CHAPTERS

JAC<SHAFT-:r-

FIOTARV

AIR

OMtF"et

.AIW

ROTARY

AIR

DAMPER

II

[FIGURE 5·2/ ROTARY

AIR

CAMPER 3/4

VIEVV]

With the modulating motor

in

the low fire posi-

tion, the arm on its shaft should

be

at an angle

of

45° below the horizontal.

The

driven arm on the

jack shaft should

be

parallel to this. Secure both

arms and fit the connecting linkage rod in place

between them. Refer

to

Figure 5-1.

Position the oil and/or gas modulating cams on

the jackshaft so that the cam follower assembly

is

between the first and second cam adjusting

screws (under the first adjusting screw for a High

Turndown Burner).

In

this position, fuel delivery

is

at low fire rate. Tighten the set screws to secure

the cams

on

the jacks haft.

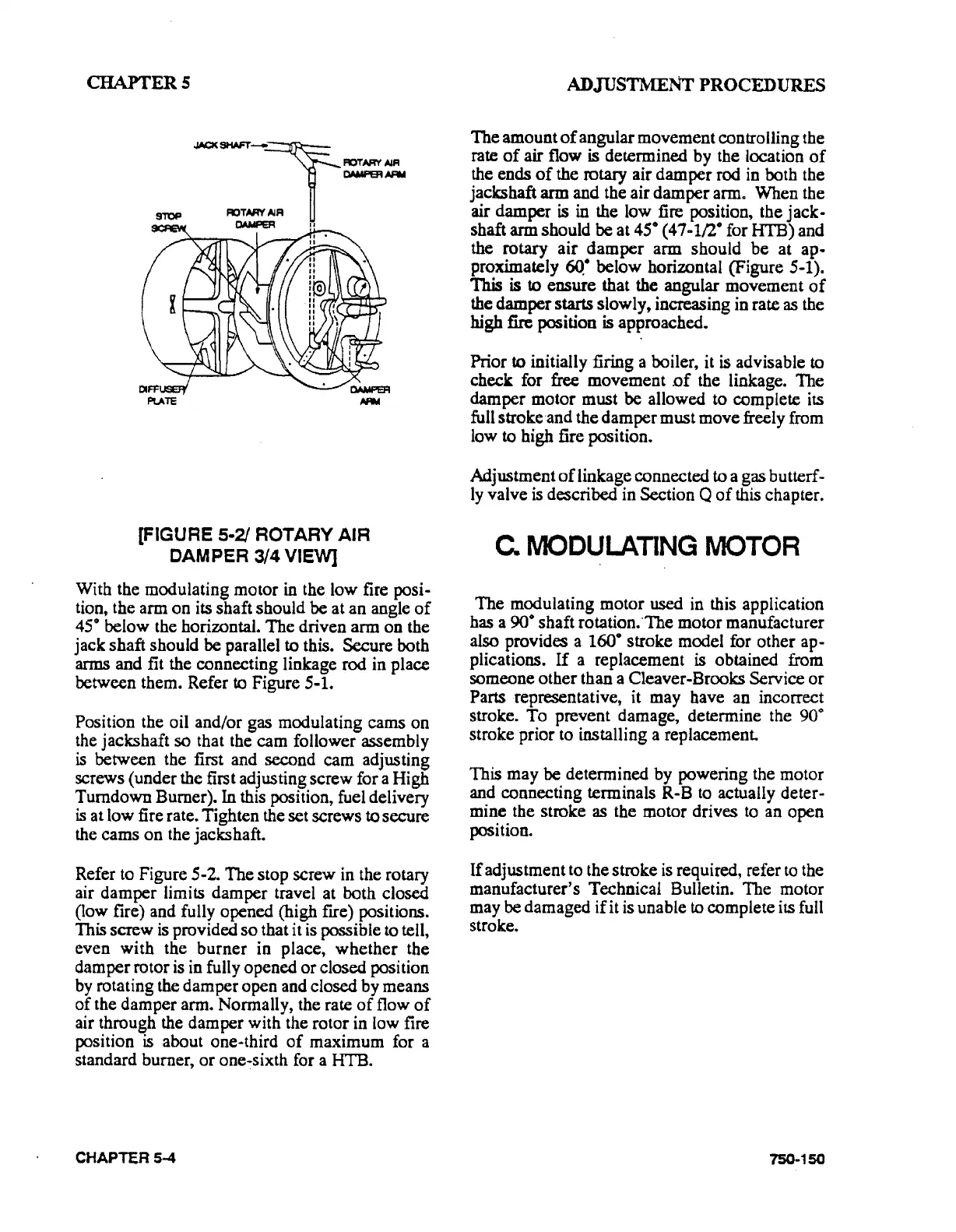

Refer to Figure 5-2.

The

stop screw in the rotary

air damper limits damper travel at both closed

(low fire) and fully opened (high fire) positions.

This

screw is provided

so

that it is possible to tell,

even

with

the

burner

in place,

whether

the

damper rotor is in fully opened

or

closed position

by

rotating the damper open and closed by means

of

the damper arm. Normally, the rate

of

flow

of

air through the damper with the rotor in low fire

position

is

about one-third

of

maximum for a

standard burner,

or

one~sixth

for a HTB.

CHAPTER 5-4

ADJUSTMENT PROCEDURES

The

amount

of

angular movement controlling the

rate

of

air flow is determined by the location

of

the ends

of

the rotary air damper rod in both the

jackshaft arm and the air damper arm. When the

air damper

is

in

the low fire position, the

jack-

shaft arm should

be

at 45• (47-1/2° for HTB) and

the rotary

air

damper

arm should

be

at ap-

proximately

6Q•

below horizontal (Figure 5-1).

This is to ensure that the angular movement

of

the damper starts slowly, increasing in rate as the

high

fire position

is

approached.

Prior

to initially firing a boiler, it

is

advisable to

check for

free

movement .of the linkage. The

damper motor must be allowed to complete its

full stroke

and

the damper must move freely from

low

to high fire position.

Adjustment

of

linkage connected to a gas butterf-

ly

valve

is

described in Section Q

of

this chapter.

C.

MODULATING

MOTOR

The

modulating motor

used

in this application

has a

90o

shaft rotation.·The motor manufacturer

also provides a

160° stroke model for other

ap·

plications.

If

a replacement

is

obtained from

someone other than a Cleaver-Brooks Service

or

Parts representative, it may have an incorrect

stroke.

To

prevent damage, determine the 90°

stroke prior to installing a replacement.

This may

be

determined by powering the motor

and connecting terminals R-B to actually deter-

mine the stroke as the motor drives

to

an open

position.

If

adjustment to the stroke

is

required, refer

to

the

manufacturer's Technical Bulletin. The motor

may be damaged

if

it is unable to complete its full

stroke.

750-150

Loading...

Loading...