CHAPTER2

(2) Partial

or

total

old

system is involved.

(3)

Conditions

may

prevent

adequate

cleaning

of

piping.

The

pressure vessel

waterside

should

be in-

spected

on

a periodic basis. This will reveal true

internal conditions and

serve

as a

check

against

conditions indicated by chemical analysis

of

the

boiler water. Inspection should be made three

months after initial starting and at regular

6-, 9-,

or

12-month intervals thereafter.

The

frequency

of

further periodic inspections will depend upon

the internal conditions found.

If

any unwanted conditions are observed, contact

your

Cleaver-Brooks

local representative for

recommendations.

Any sludge, mud,

or

sediment

found will have to

be

flushed out.

The

effectiveness

of

the blow

..

down

practiced

on

steam

boilers

should

be

verified and

scheduling

or

frequency

of

blow-

down

may have to be revised.

The

need for

periodic draining

or

washout

will also be indi

~

cated.

Any

oil

or

grease present

on

the heating surfaces

should be removed promptly by a

boil-out with ·

an

alkaline detergent solution.

NOTE:

Temperature

of

initial

fill

of

water for hydrostatic tests, boil-

out,

or

for

normal

operation

should be as stated in

the

ASME

Boiler Code.

F.

BOIL-OUT

OF

A NEW UNIT

The

internal surfaces

of

a newly installed boiler

may have oil, grease

or

other

protective coatings

used

in

manufacturing.

Such

coatings must be

removed since they lower the heat transfer rate

and could cause over-heating

of

a tube. Before

boiling

out

procedures may begin, the burner

CHAPTER 2-8

THE

PRESSURE VESSEL

should be ready for

fuing.

The

operator must

be

familiar

with

the

procedure

outlined

under

burner operation.

!WARNING

Use

of

a suitable face mask,

gog-

gles, rubber gloves, and protec-

tive

garments

Is

strongly

recommended when handling

or

mixing caustic chemicals.

Do

not

permit the

dry

material

or

the con-

centrated

solution

to

come

in

contact

with

skin

or

clothing.

Failure

to

follow

these precau-

tions

could result in serious per-

sonal

injury

or

death.

Your Cleaver-Brooks local representative

wiU

be

able to

recommend a cleaning

or

boil-out prOce-

dure. In the

event

such

service is unavailable

or

is

yet unscheduled, the following information

may be

of

assistance.

There are several chemicals suitable for this

pur-

pose.

Soda

ash (sodium carbonate) and caustic

soda (sodium hydroxide at the rate

of

3 to 5

pounds

each

per

1,000 pounds

of

water, along

with a small

amount

of

laundry detergent added

as

a wetting agent is

one

combination often used.

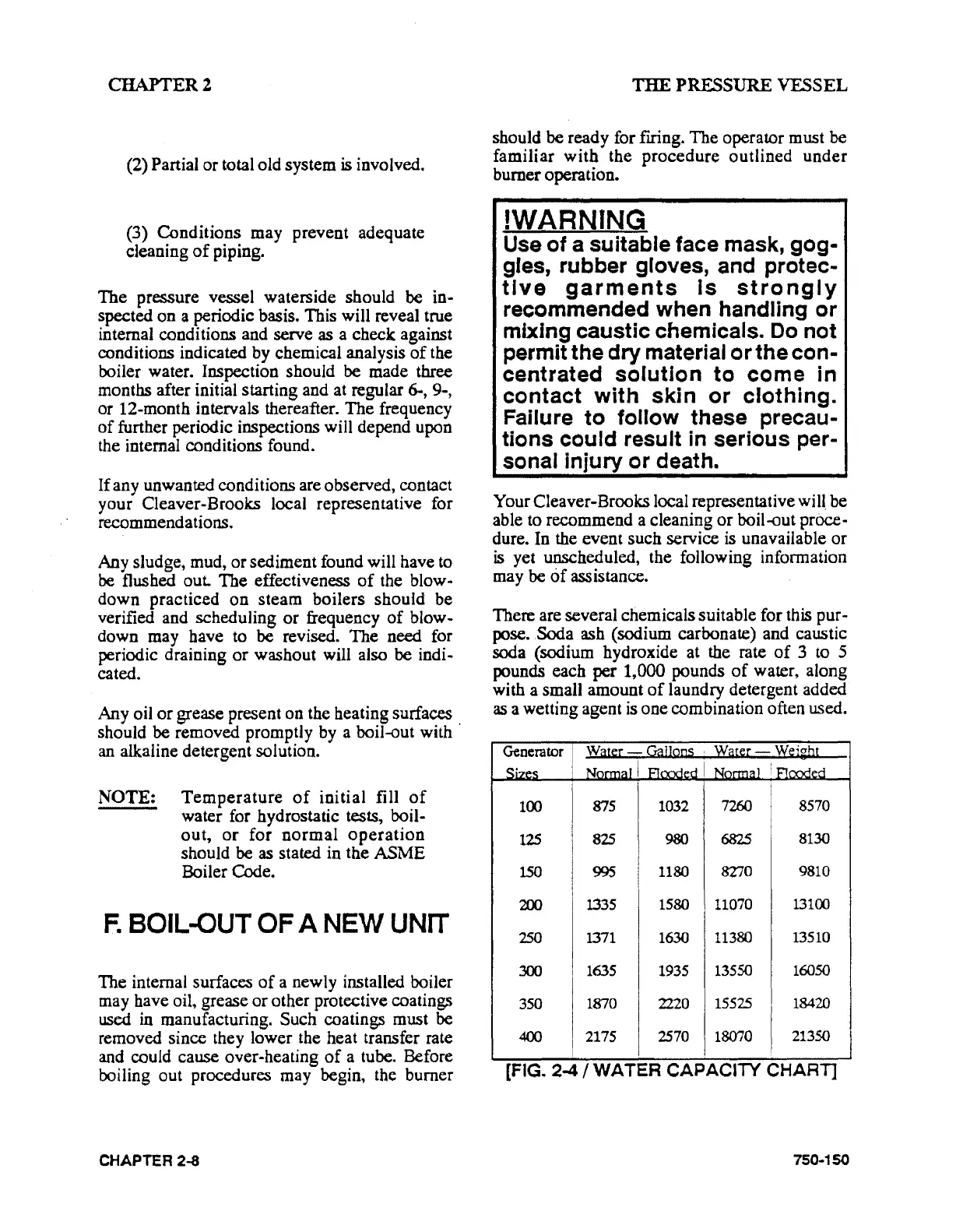

Generator

JYatcr-

O:allccs

, JYatct-

Wci~bt

Si?P:<IOI.

Normal

I

F"

"'lOCrec

I

Nnrm~l

I

F1CXXIea

100

875

1032

7260

8570

125

825

980

6825

8130

150

995

1180

8270

9810

200

1335

1580

11070

13100

250

1371

1630

11380

13510

300

1635

1935

13550

16050

350

1870

2220

15525

18420

400

2175 2570

18070

21350

(FIG. 2-4 I WATER

CAPACirf

CHARn

750-150

Loading...

Loading...