CHAPTERS

A.

GENERAL

While each boiler is tested for correct operation

before shipment from the factory, variable con-

ditions such

as

burning characteristics

of

the

fuel

and

operating load conditions may require fur-

ther adjustment after installation

to

assure maxi-

mum

operating efficiency

and

economy.

ADJUSTMENT

PROCEDURES

A combustion efficiency analysis made during

the

initial start-up

will

help to determine what

additional adjustments are required

in

a par-

ticular installation.

Prior to placing the boiler into service, a complete

inspection should be made

of

all controls,

con~

necting piping, wiring, and all fastenings such

as

nuts, bolts and setscrews to

be

sure that

no

damage or misadjustments occurred during ship-

ment

and

installation.

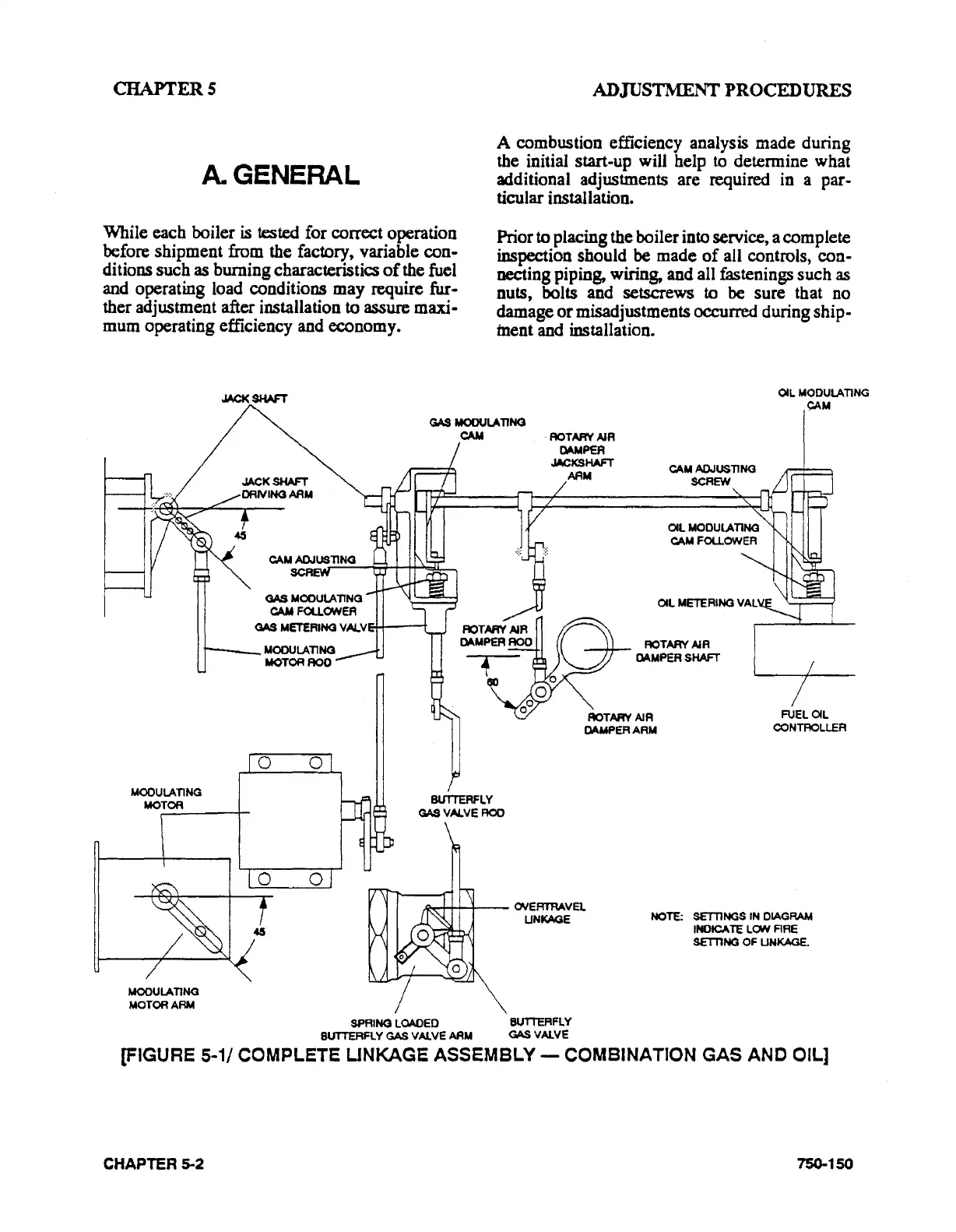

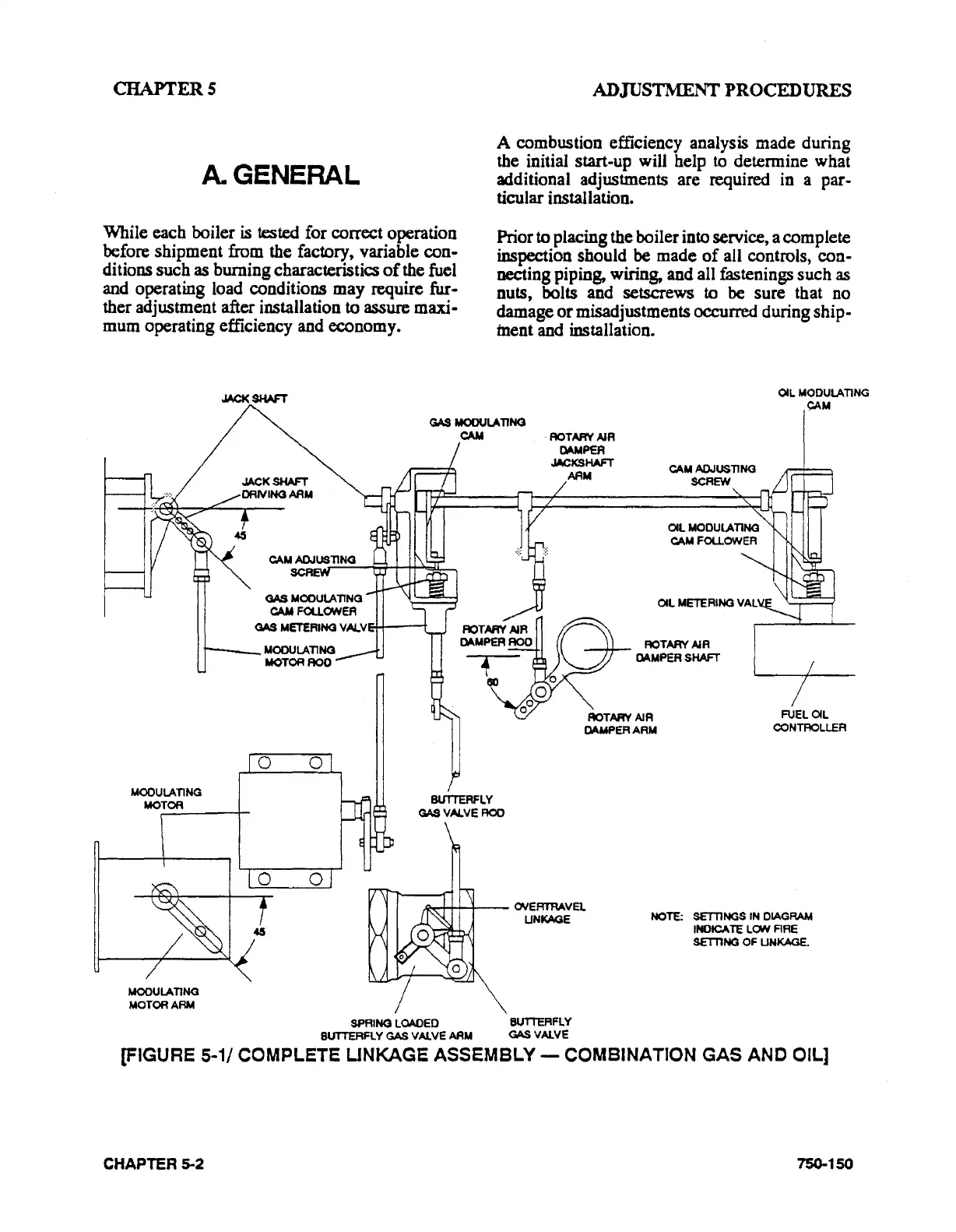

OIL MODULATING

~M

GAS

MODULATING

MODULATING

MOTOR

MODULATING

MOTOR

ARM

CAM

·ROTARY

AIR

BUTTERFLY

GAS

VAL.VE

ROO

I:WotPER

JACKS

HAFT

AAM

.o..--~-..,...;..~-

OVERTRAVEl

UNKAGE

SPRINQ LOADED

8U1TERFL

Y

BUTTERFLY

GAS

VAlVE

AAM

GAS

VAlVE

CAM

ADJUSTING

SCREW

OIL METERING VAL

ROTARY AIR

CAMPER

SHAFT

FUEL

OIL

CONTROLLER

NOTE:

SETllNGS

IN

DIAGRAM

INDICATE

LON

ARE

SETllNG

OF

UNKAGE.

[FIGURE 5·1/ COMPLETE UNKAGE

ASSEMBLY-

COMBINATION GAS AND OIL]

CHAPTER 5-2 750-150

Loading...

Loading...