CHAPTERS

L

v

-~

/

w

3

L

,

u..

/

;::;

N

v

0

0

/

/

~

w

/"'

0

a:

/

w

a.

/

v

,

9 8 7 6

54

3 2

-

PERCENT

02

IN

FLUE

GAS

60 50 40 30 20 10

PERCENT

EXCESS

AIR

12

-"'

1'1

'\

1\

10

'

9

8

7

6

5

0

ADJUSTMENT

PROCEDURES

I

I

!...

'

'"

\

I

""'

'

I

i\

I

\

I

'

I

1\

I

I

\

I

I

\:

~

2 3 4 5 6

PERCENT

CO---

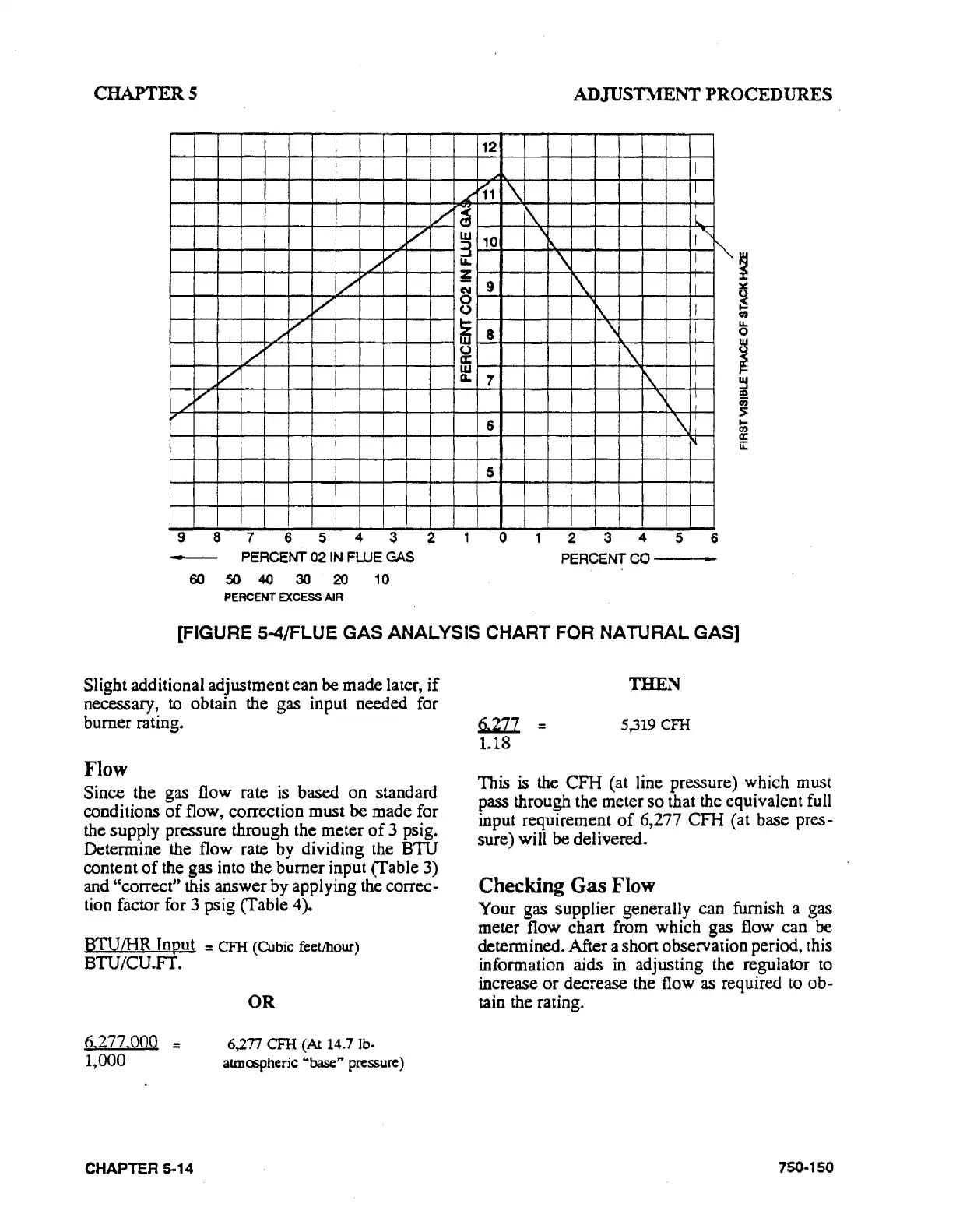

[FIGURE 5-4/FLUE GAS ANALYSIS CHART FOR NATURAL GAS]

Slight additional adjustment can be made later,

if

necessary,

to

obtain the gas input needed for

burner rating.

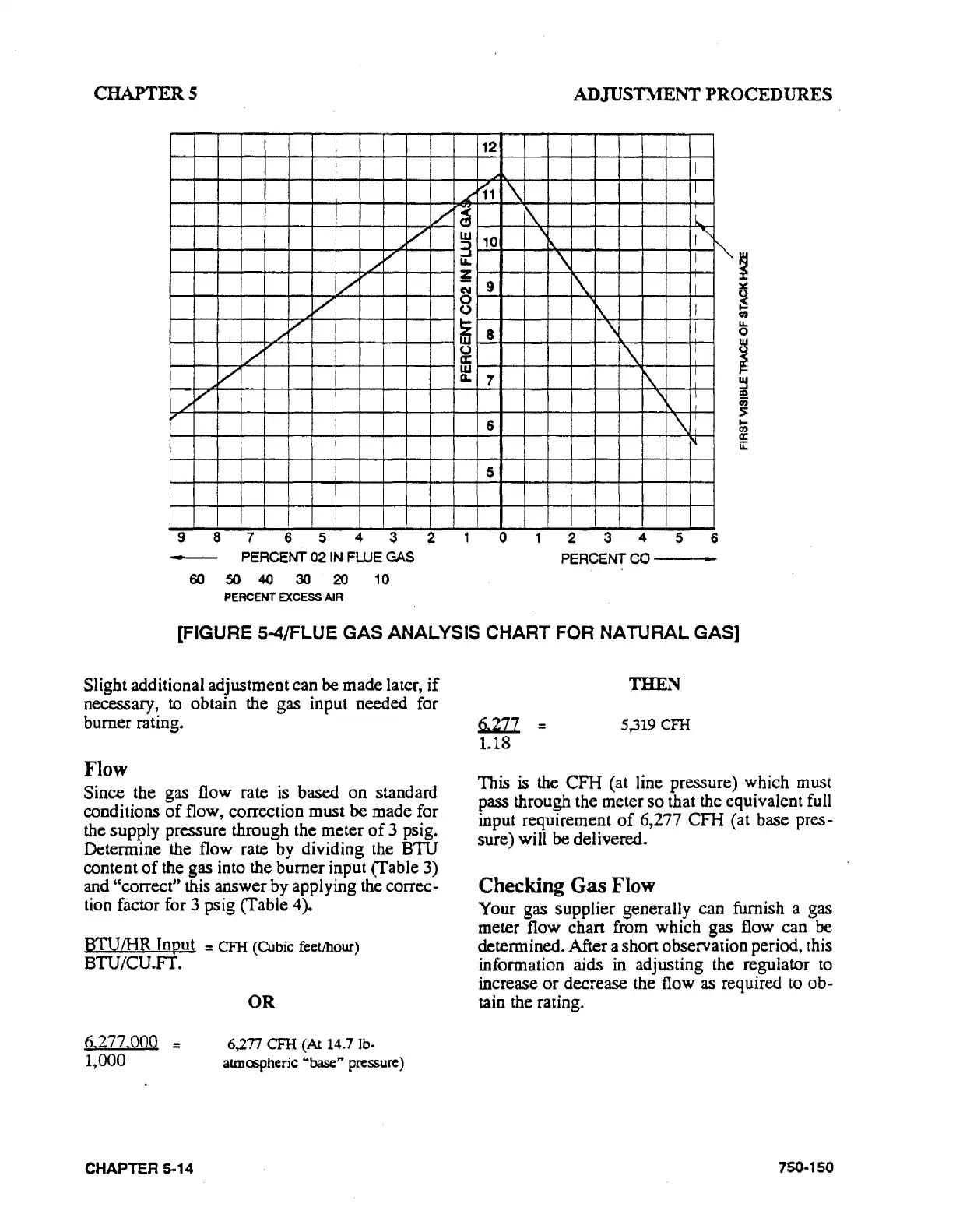

Flow

Since the gas flow rate

is

based

on

standard

conditions

of

flow, correction must be made for

the supply pressure through the meter

of

3 psi

g.

Determine the flow rate by dividing the BTU

content

of

the gas into the burner input (Table 3)

and "correct" this answer by applying the correc-

tion factor for 3 psig (Table 4).

BTUIHR Input = CFH (Cubic feet/hour)

BTU/CU.Fr.

6.277.000

::

1,000

CHAPTER 5-14

OR

6)."n

CFH (A114.7 lb·

atmcspheric "base" pressure)

Q;]JJ_

::

1.18

THEN

5,319 CFH

This

is

the

CFH

(at line pressure) which

must

pass through the meter so that the equivalent full

input requirement

of

6,277 CFH (at base pres-

sure) will be delivered.

Checking

Gas

Flow

Your gas supplier generally can furnish a gas

meter flow chart from which gas flow can be

determined. After a short observation period, this

information aids

in

adjusting the regulator

to

increase

or

decrease the flow

as

required

to

ob-

tain the rating.

750

..

150

Loading...

Loading...