CHAPTERS

Final adjustment

of

gas fuel is carried out by

means

of

the adjusting screws

in

the gas modulat-

ing

cam

while performing a combustion efficien-

cy

analysis. See Section Q for details.

NOTE:

The

information given

in

this

sec-

tion is for all practical purposes

sufficient to set and adjust

con-

trols for gas input.

Your

gas

sup·

plier can,

if

necessary, furnish

exact correction factors that take

into consideration

BTU

content,

exact

base

pressure,

specific

gravity, ·temperature, etc.,

of

the

gas

used.

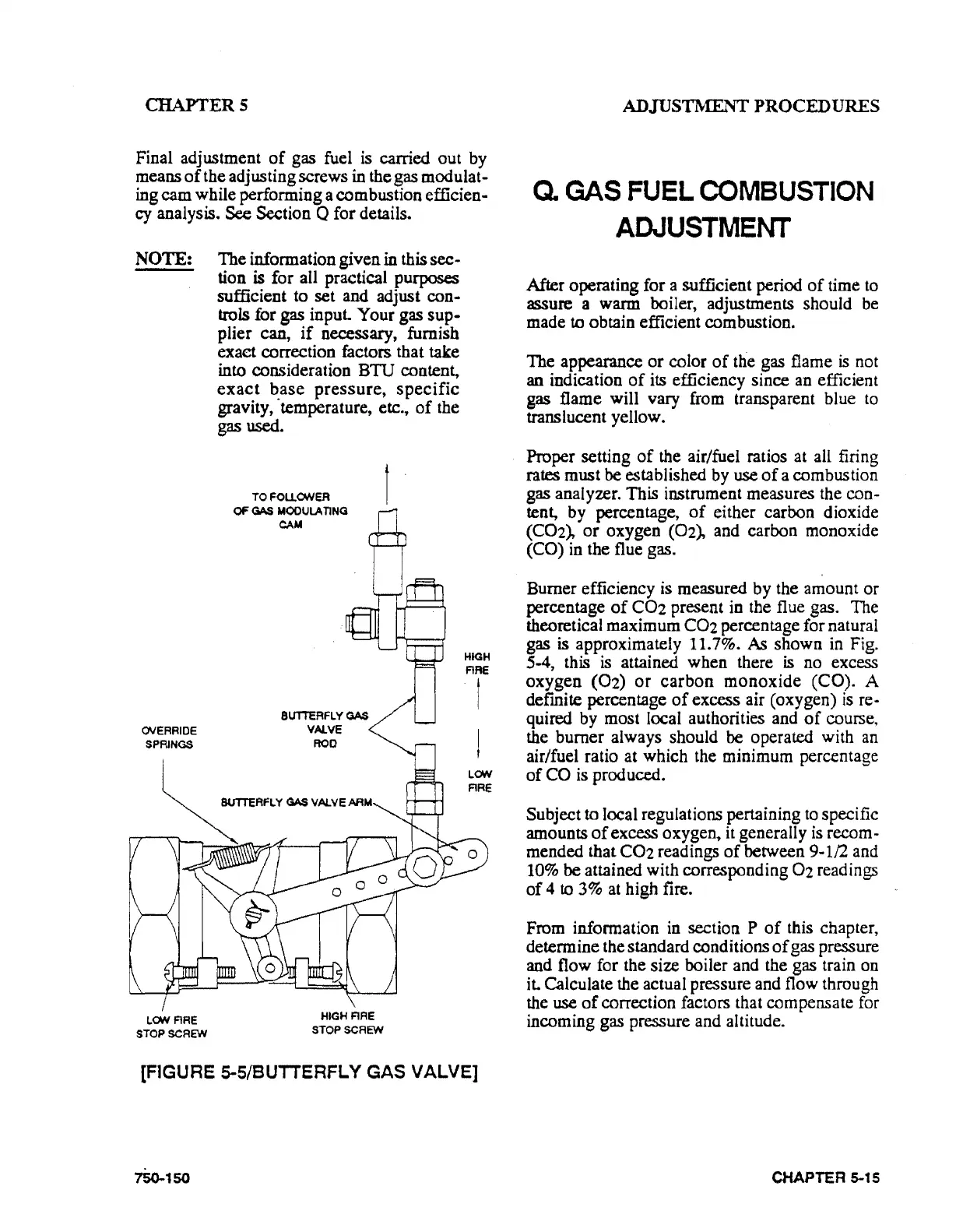

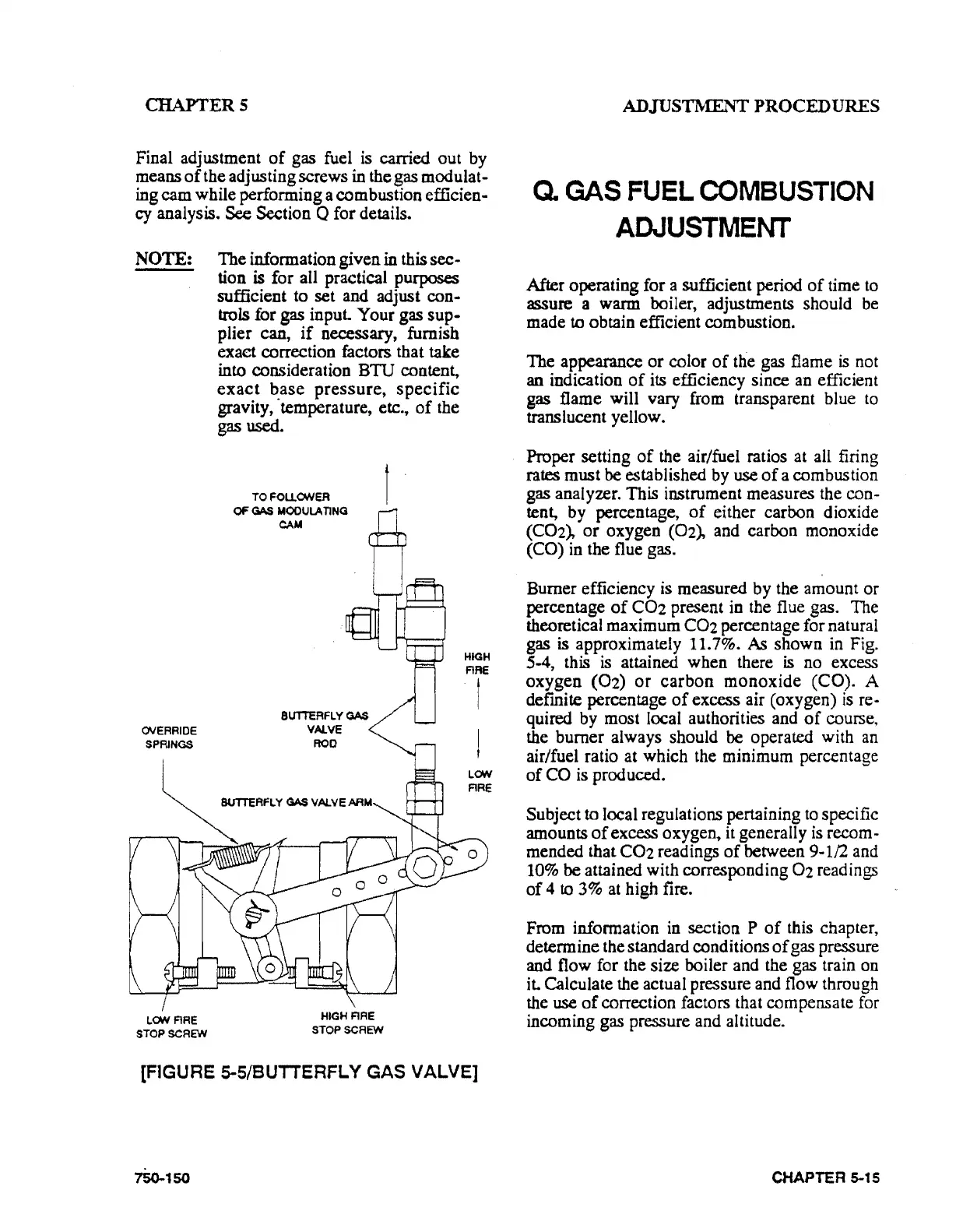

OVERRIDE

SPRINGS

LON ARE

STOP

SCREW

TOFOUONER

OF

GAS

MOOULA

TING

CAM

HIGH

ARE

STOP

SCREW

HIGH

ARE

t

!

LON

ARE

[FIGURE 5-5/BUTTERFLY GAS VALVE]

1So..1so

ADJUSTMrnNTPROCEDURES

Q.

GAS

FUEL

COMBUSTION

ADJUSTMENT

After operating for a sufficient period

of

time

to

assure a warm boiler, adjustments should be

made

to obtain efficient combustion.

The

appearance

or

color

of

the gas flame

is

not

an indication

of

its

efficiency since an efficient

gas

flame will vary from transparent blue

to

translucent yellow.

Proper setting

of

the air/fuel ratios at all firing

rates must be established by use

of

a combustion

gas analyzer. This instrument measures the

con-

tent, by percentage,

of

either carbon dioxide

(COz),

or

oxygen (Oz), and carbon monoxide

(CO) in the flue gas.

Burner efficiency is measured by the amount

or

percentage

of

C02

present in the flue gas. The

theoretical maximum

C02

percentage for natural

gas is approximately 11.7%.

As

shown

in Fig.

S-4, this

is

attained when there is no excess

oxygen

(02)

or

carbon

monoxide

(CO). A

definite percentage

of

excess air (oxygen)

is

re·

quired by most local authorities and

of

course,

the burner always should be operated with an

air/fuel ratio at which the minimum percentage

of

CO is produced.

Subject

to local regulations pertaining

to

specific

amounts

of

excess oxygen, it generally is recom-

mended that

C02

readings

of

between 9-1/2 and

10% be attained with corresponding Oz readings

of

4 to

3%

at high fire.

From information

in

section P

of

this chapter,

detennine the standard conditions

of

gas pressure

and flow for the size boiler and the gas train on

it. Calculate the actual pressure and flow through

the use

of

correction factors that compensate for

incoming gas pressure and altitude.

CHAPTER 5-15

Loading...

Loading...