CHAPTERS

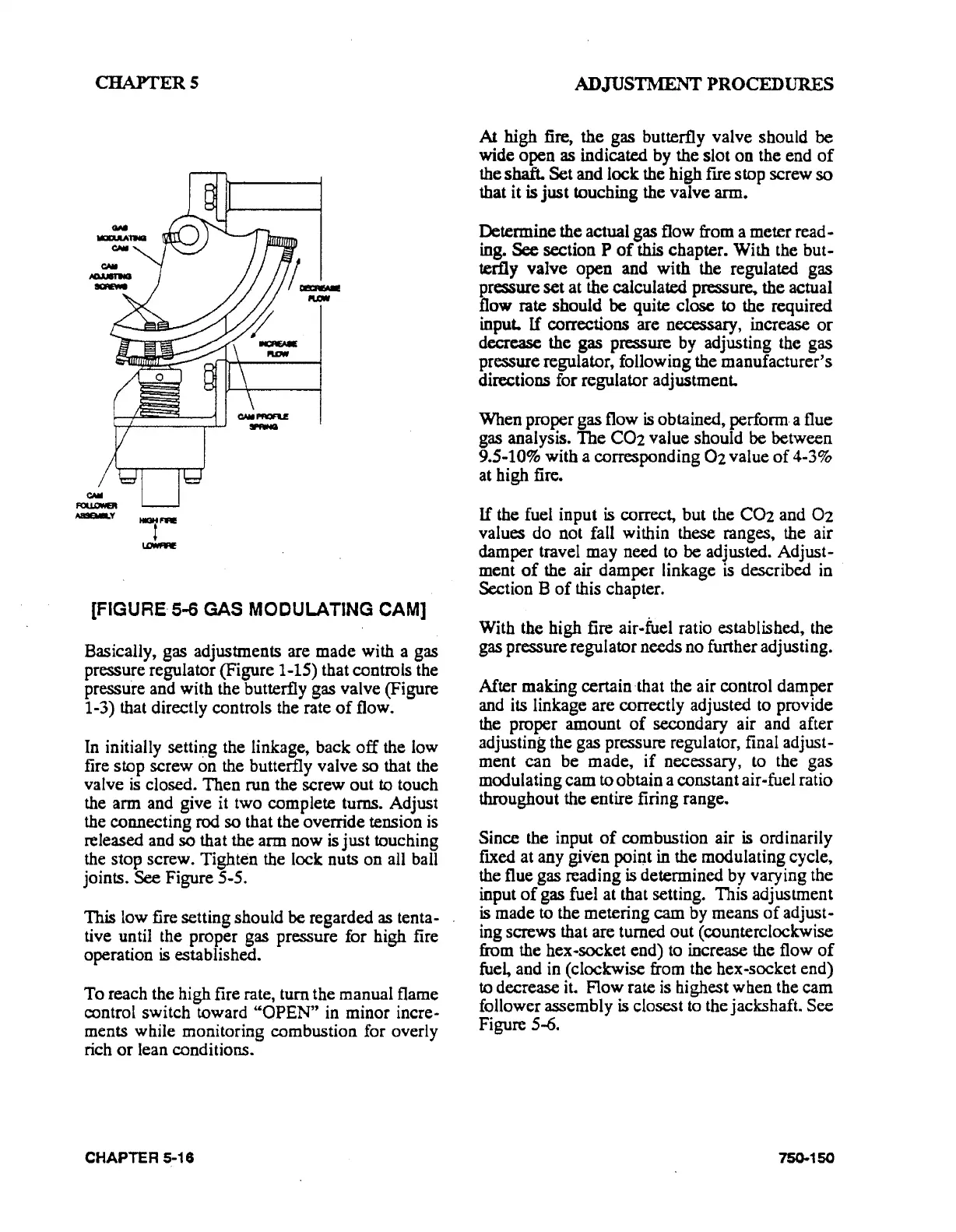

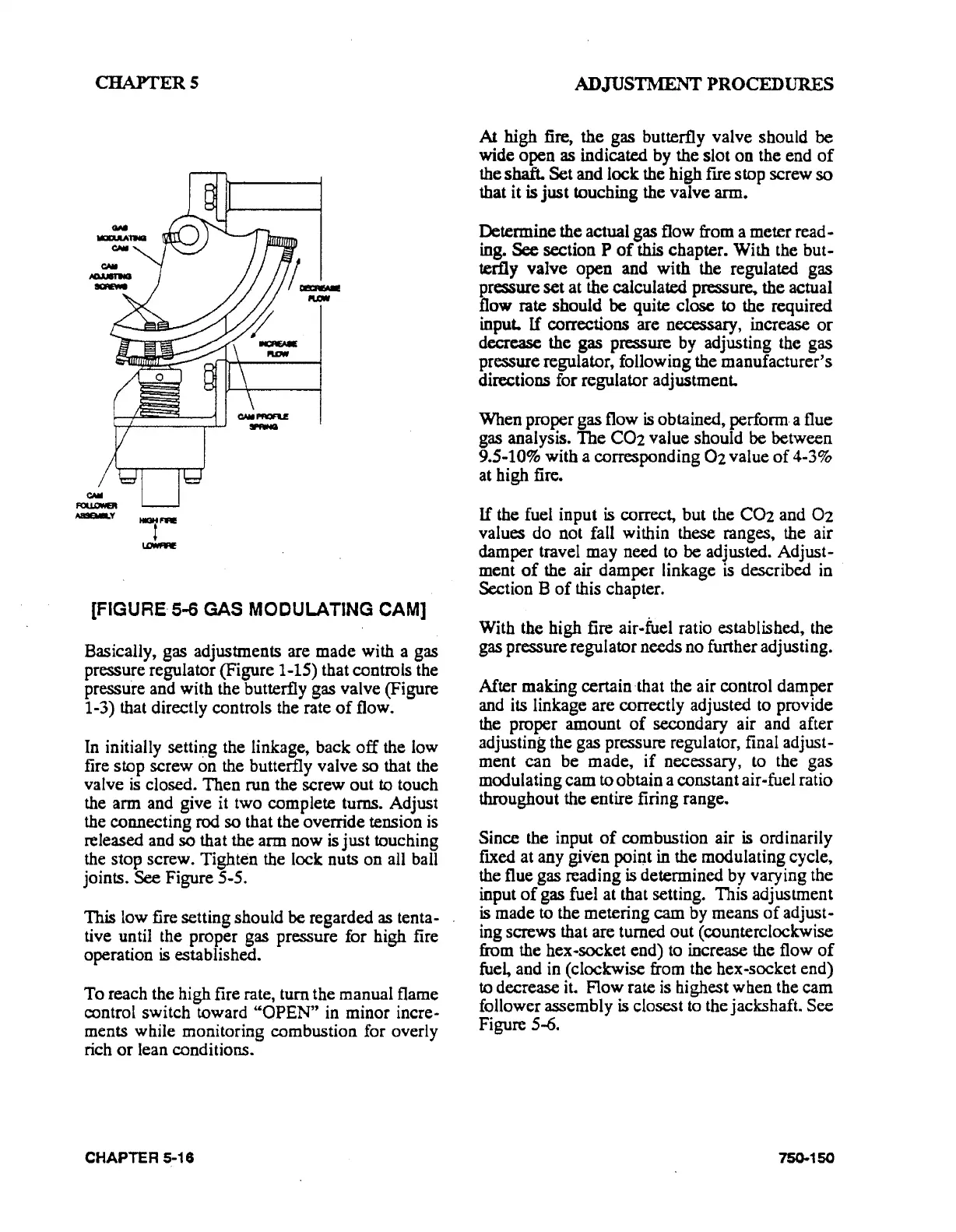

(FIGURE· 5-6 GAS MODULATING CAM]

Basically, gas adjustments are made with a gas

pressure regulator (Figure 1-15) that controls the

pressure and with the butterfly gas valve (Figure

1-3) that directly controls the rate

of

flow.

In initially

setti~g

the linkage, back

off

the low

fire

stop

screw

on

the butterfly valve

so

that the

valve

is

closed.

Then

run the screw

out

to

touch

the arm and give it two complete turns. Adjust

the connecting

rod

so

that the override tension is

released and

so

that the arm

now

is

just

touching

the stop screw. Tighten the lock nuts

on

all ball

joints.

See Figure S-5.

This low fire setting should be regarded as tenta-

tive until the proper gas pressure for high fire

operation

is

established.

To

reach the high fire rate,

tum

the manual flame

rontrol switch toward

"OPEN"

in minor incre-

ments while monitoring combustion for overly

rich

or

lean conditions.

CHAPTER 5-16

ADJUSTMENT PROCEDURES

At

high fire, the gas butterfly valve should

be

wide

open

as indicated by the

slot

on

the end

of

the shaft.

Set

and lock the high

fue

stop screw

so

that it is

just

touching the valve arm.

Determine the actual gas flow from a meter read-

ing.

See section P

of

this chapter. With the but-

terfly

valve

open

and

with

the regulated gas

pressure

set

at the calculated

pressu~

the actual

flow rate should

be

quite close to the required

input.

If

corrections are necessary, increase

or

decrease the gas pressure by adjusting the gas

pressure regulator, following the manufacturer's

directions for regulator adjustment.

When proper gas flow

is

obtained, perform. a flue

gas analysis.

The

C02

value should be between

9.5-10% with a corresponding

02

value

of

4-3%

at high fire.

If

the fuel input

is

correct, but the

C02

and

02

values

do

not fall within these ranges, the air

damper travel may need to be adjusted. Adjust-

ment

of

the air

damper

linkage

is

described in ·

Section B

of

this chapter.

With the high fire

air-fuel ratio established, the

gas

pressure regulator needs no further adjusting.

After making certain

·that the air control

damper

and its linkage are correctly adjusted to provide

the proper amount

of

secondary air and after

adjusting the gas pressure regulator, final adjust-

ment

can

be

made,

if

necessary, to the gas

modulating cam to obtain a constant air-fuel ratio

throughout the entire firing range.

Since the input

of

combustion air

is

ordinarily

ftxed at any

given poiQt in the modulating cycle,

the flue gas reading

is

determined by varying the

input

of

gas fuel at that setting. This adjustment

is

made to the metering

cam

by means

of

adjust-

ing screws that are turned

out

(counterclockwise

from the hex-socket end) to increase the flow

of

fue~

and in (clockwise from the hex-socket end)

to decrease it. Flow rate is highest when the cam

follower assembly

is

closest to the jack:shaft. See

Figure

S--6.

75().150

Loading...

Loading...