CHAPTER4

STARTING AND OPERATING INSTRUCfiONS

D.

ATOMIZING

AIR

The supply and pressure

of

the atomizin'g air on

an

oil fired burner should be checked. Before

starting,

inspect the oil pump lube oil level. Add

oil

if

necessary to bring the level to the mid-point

or slightly higher

of

the sight glass. Use SAE 20

detergent oil

of

a grade mentioned

in

Chapter 7

and

fill in accordance with the instructions given

there.

Check the oil level

of

the air intake strainer.

To

verify air flow and pressure, place the run/test

switch on the program relay

to

the test position.

If

this

is

a combination fuel burner, make sure

that the gas/oil selector switch

is

set

to

"oil." Tum

the

burner switch on. The burner will cycle

to

the

low

fire pre-purge position and stop there.

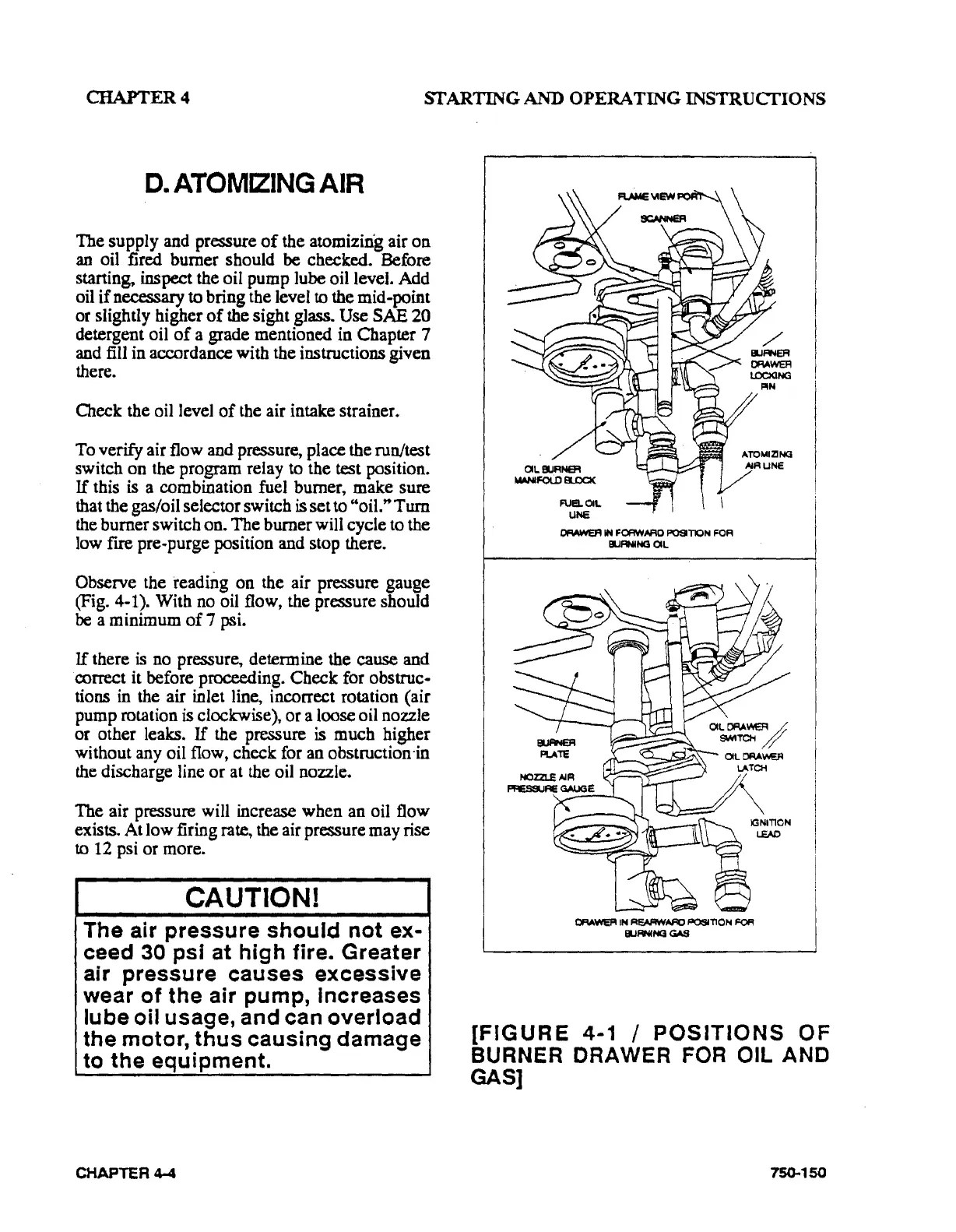

Observe the

readmg on the air pressure gauge

(Fig. 4-1). With

no

oil flow, the pressure should

be

a minimum

of

7

psi.

If

there

is

no

pressure, determine the

cause

and

correct it before proceeding. Check for obstruc·

tions

in

the air inlet line, incorrect rotation (air

pump rotation

is

clockwise), or a loose oil nozzle

or other leaks.

If

the pressure

is

much higher

without

any

oil flow, check for

an

obstruction·in

the

discharge line or at

the

oil nozzle.

The air pressure will increase when an oil flow

exists. At low firing rate, the air pressure may rise

to 12 psi or more.

CAUTION!

The

air

pressure

should

not

ex-

ceed 30

psi

at

high

fire. Greater

air

pressure

causes

excessive

wear

of

the

air

pump,

Increases

lube

oil

usage, and can

overload

the

motor,

thus

causing

damage

to

the

equipment.

CHAPTER4-4

FUB.OIL

UNE

0RAweA

IN

FOFIWAFIO

POSITION

FOR

EI.IRNING

OIL

OAAWER

IN

REAFIWAAD

POSITION

~

EI.IRNING

GAS

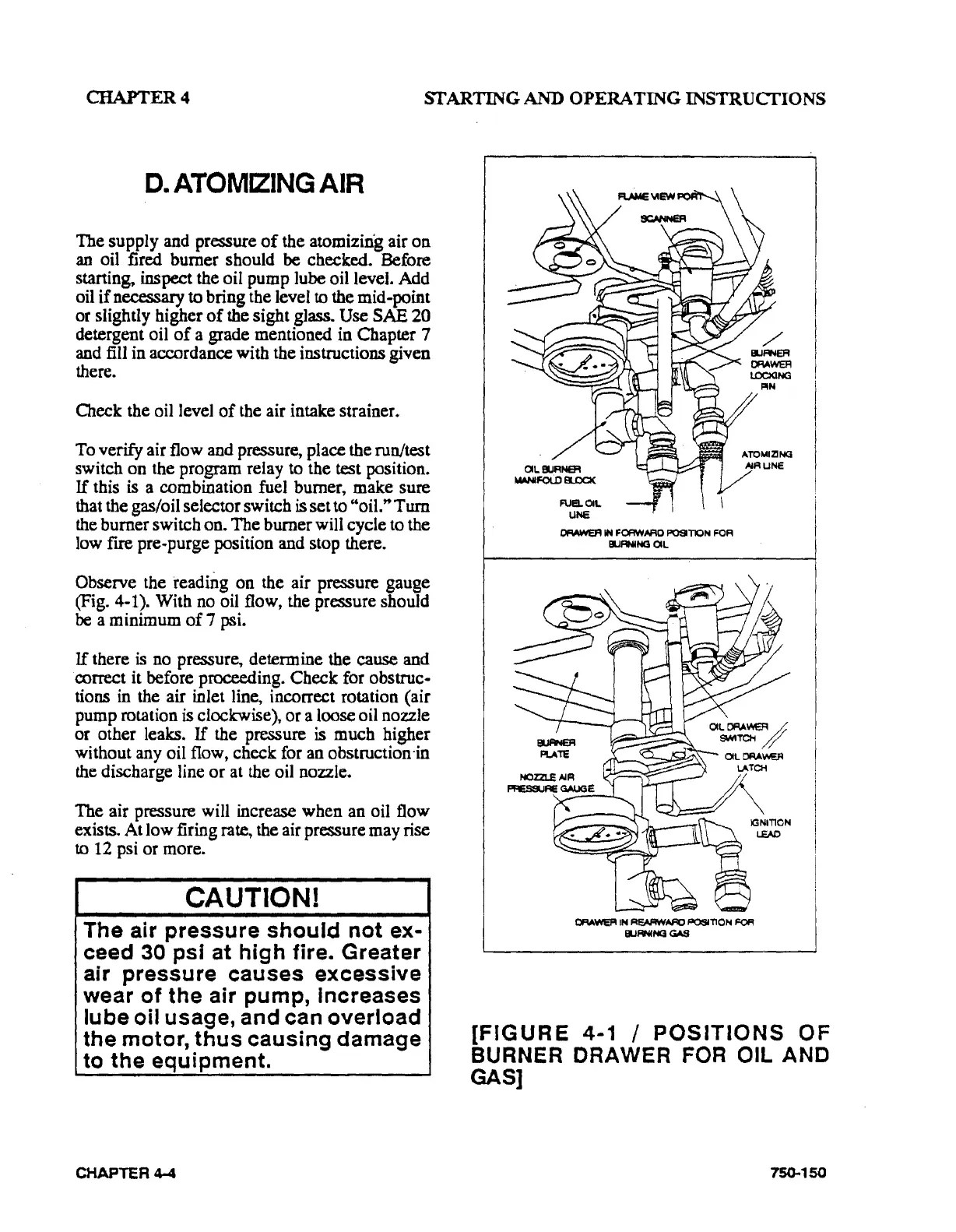

[FIGURE

4-1 I

POSITIONS

OF

BURNER DRAWER

FOR

OIL AND

GAS]

750-150

Loading...

Loading...