71Fault elimination

8.2 Malfunction lists

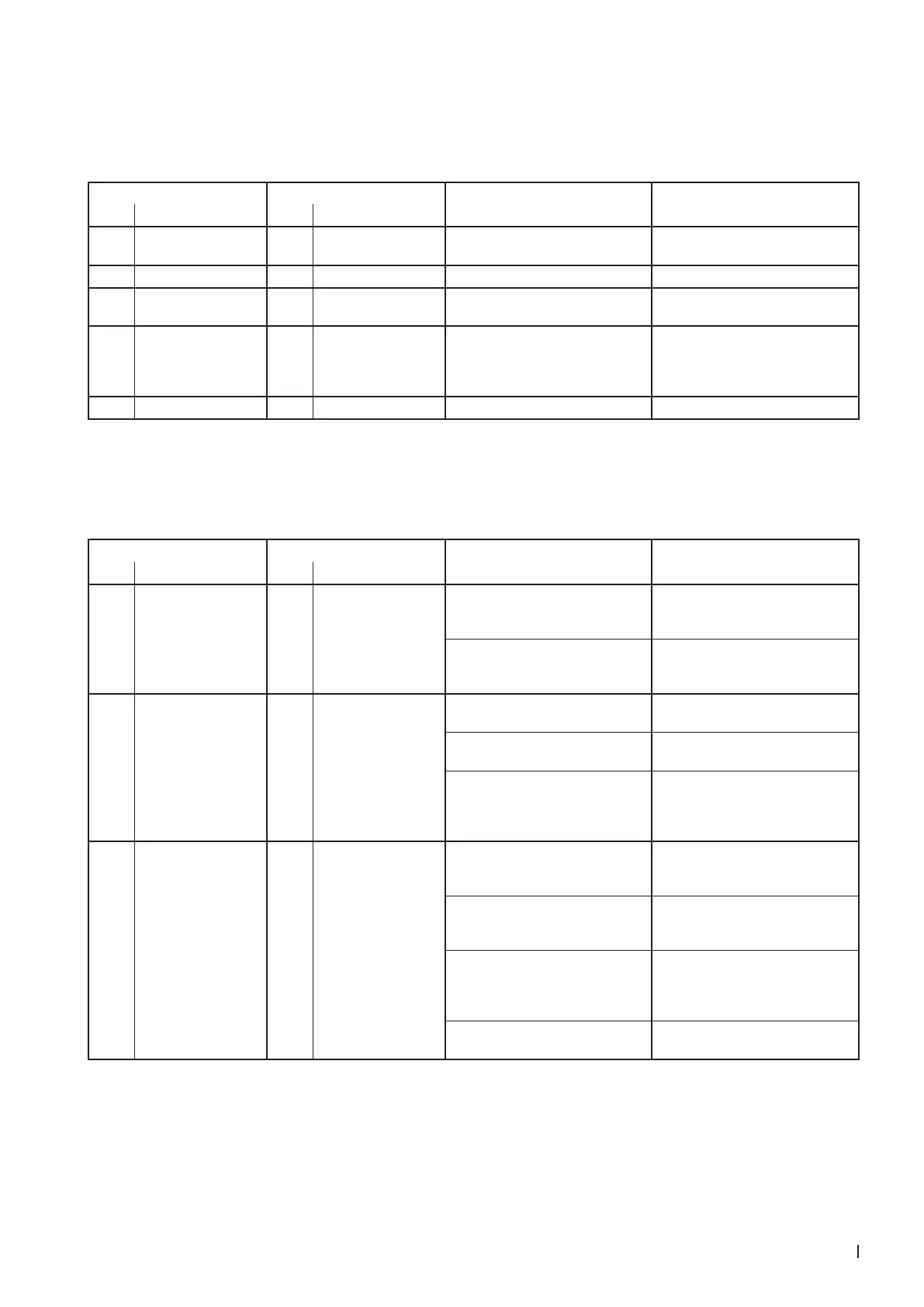

8.2.1 System faults

Warning Error Cause Remedy

Code Malfunction Code Malfunction

E1 Smart Card missing No Smart Card installed on the

control board.

Install Smart Card or start test run.

––– ––– E2 Smart Card is empty No data stored on the Smart Card. Install new Smart Card.

––– ––– E3 Smart Card is

defective

Invalid data stored on the Smart Card. Install new Smart Card.

––– ––– E4 Smart Card is

incompatible

The installed Smart Card is not com-

patible with the hardware of the unit or

with the basic settings of the control

electronics.

Install correct Smart Card. Let your

Condair service technician adjust

the basic settings.

––– ––– E10 Hardware fault Control board defective. Replace control board.

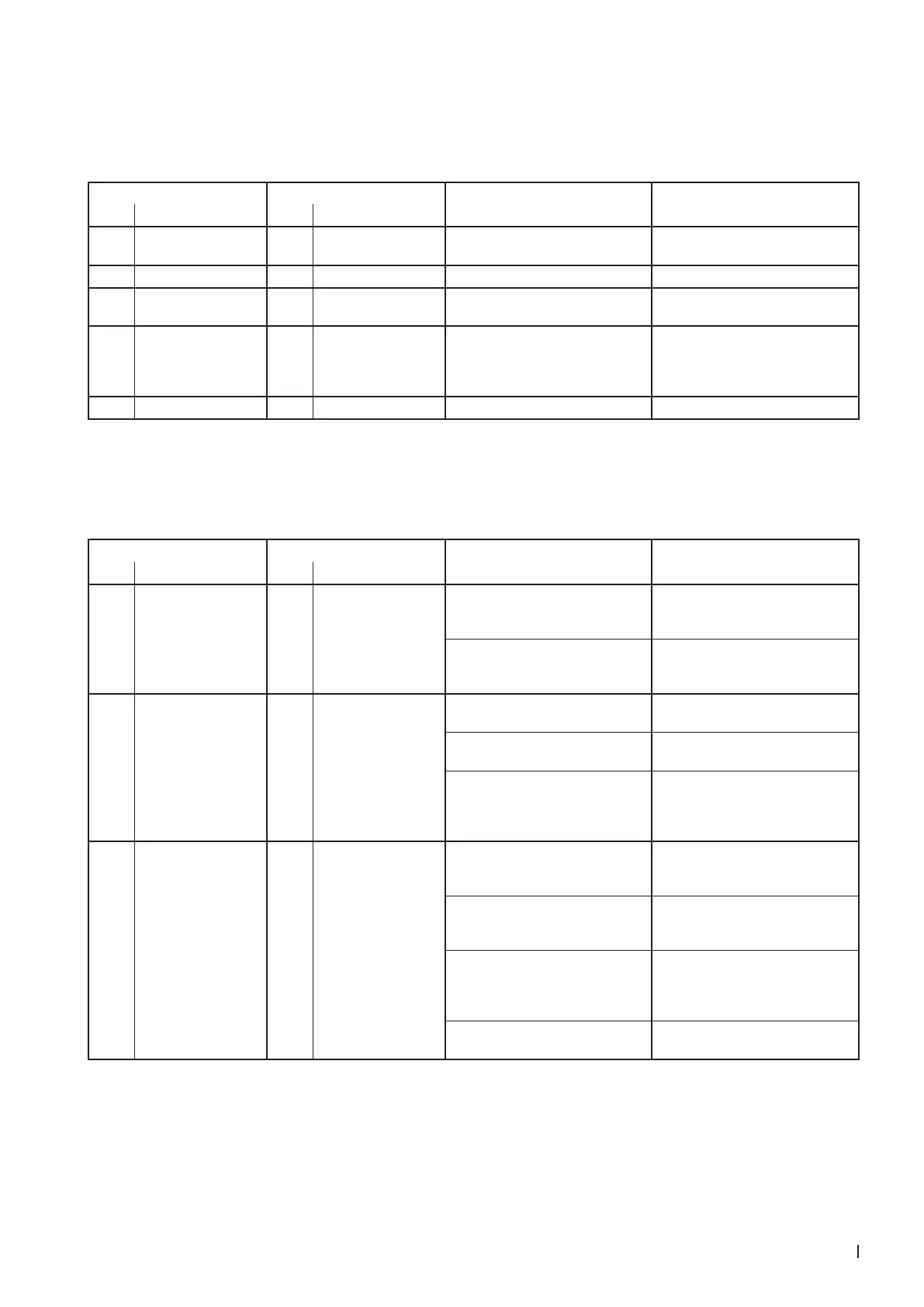

8.2.2 Unit faults

Warning Error Cause Remedy

Code Malfunction Code Malfunction

W20 External safety

chain is open

––– ––– One or more monitoring devices (e.g.

safety thermostat) of the external

safety loop have responded.

Check monitoring devices.

No cable bridge connected to termi-

nals "SC1" and "SC2" if no monitoring

devices are connected.

Connect the cable bridge to terminals

"SC1" and "SC2".

W21

Max.llinglevelof

steam cylinder

reached

E21 Max.llinglevelof

steam cylinder

reached but

no heating current

Water conductivity too low (after initial

operation).

Wait until the mineral content of the

cylinder has increased

Water conductivity too low for type of

steam cylinder.

Select correct steam cylinder type.

Phase failure heating voltage. Check electrical isolator in the mains

supply line(s) and switch on if applica-

ble. Check mains fuse(s) and replace

if applicable.

W22

Permissiblelling

time exceeded (20

minutes)

E22

Permissiblelling

time exceeded (more

than 4 hours)

Water supply obstructed/shut-off

valve closed/water pressure too low.

Inspect water supply (lter, water pip-

ing, etc.), check/open shut-off valve,

check water pressure.

Inlet valve blocked or defective. Inspect strainer insert in the inlet valve,

if applicable clean strainer insert or

replace inlet valve.

Excessive back pressure in the steam

line (duct pressure too high, steam

line too long or kinked), causing water

loss via lling cup.

Check duct pressure, inspect steam

installation. If applicable install pres-

sure compensation kit (see options).

Leakage in the water system. Inspect water system and seal if

necessary.

Loading...

Loading...