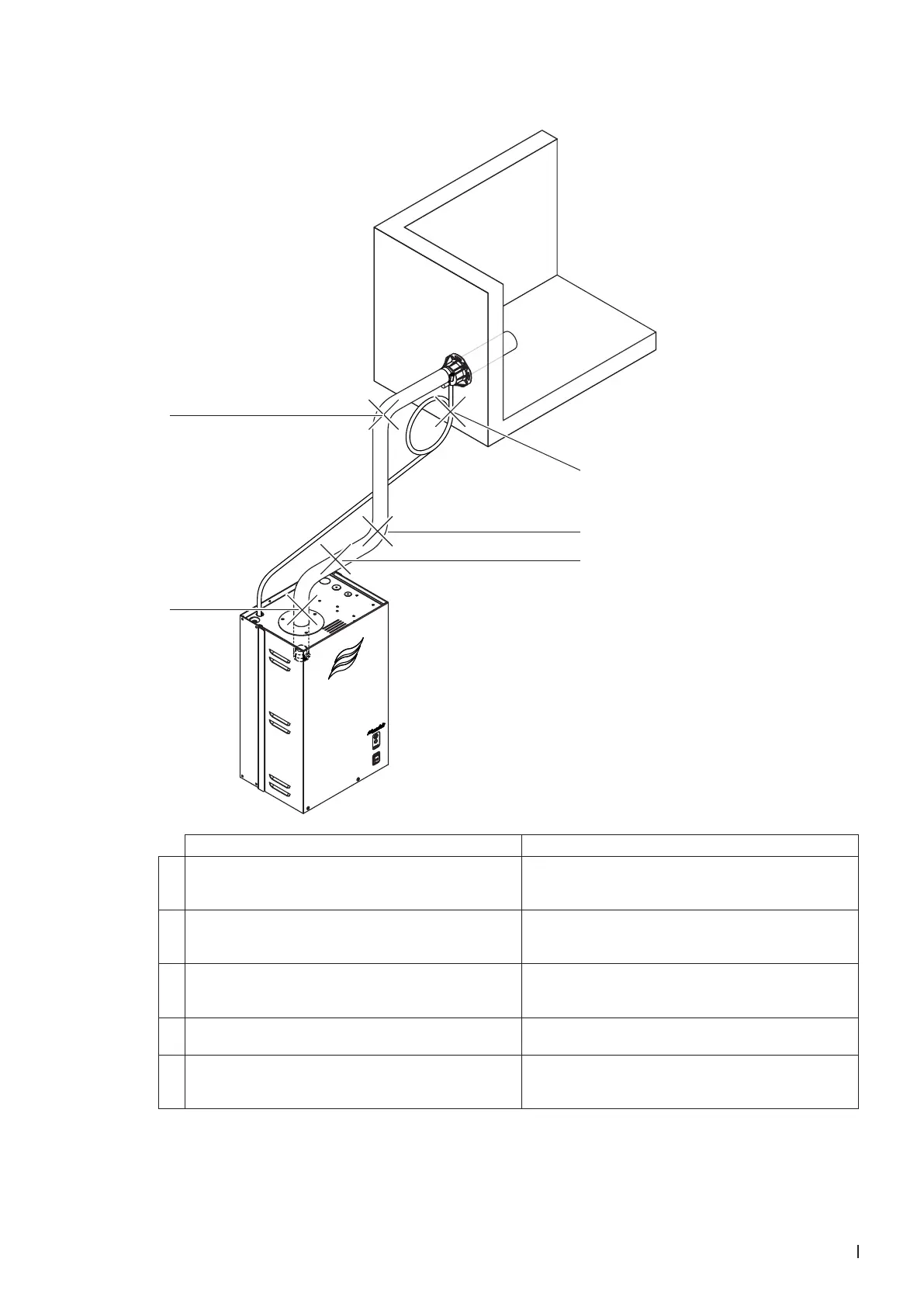

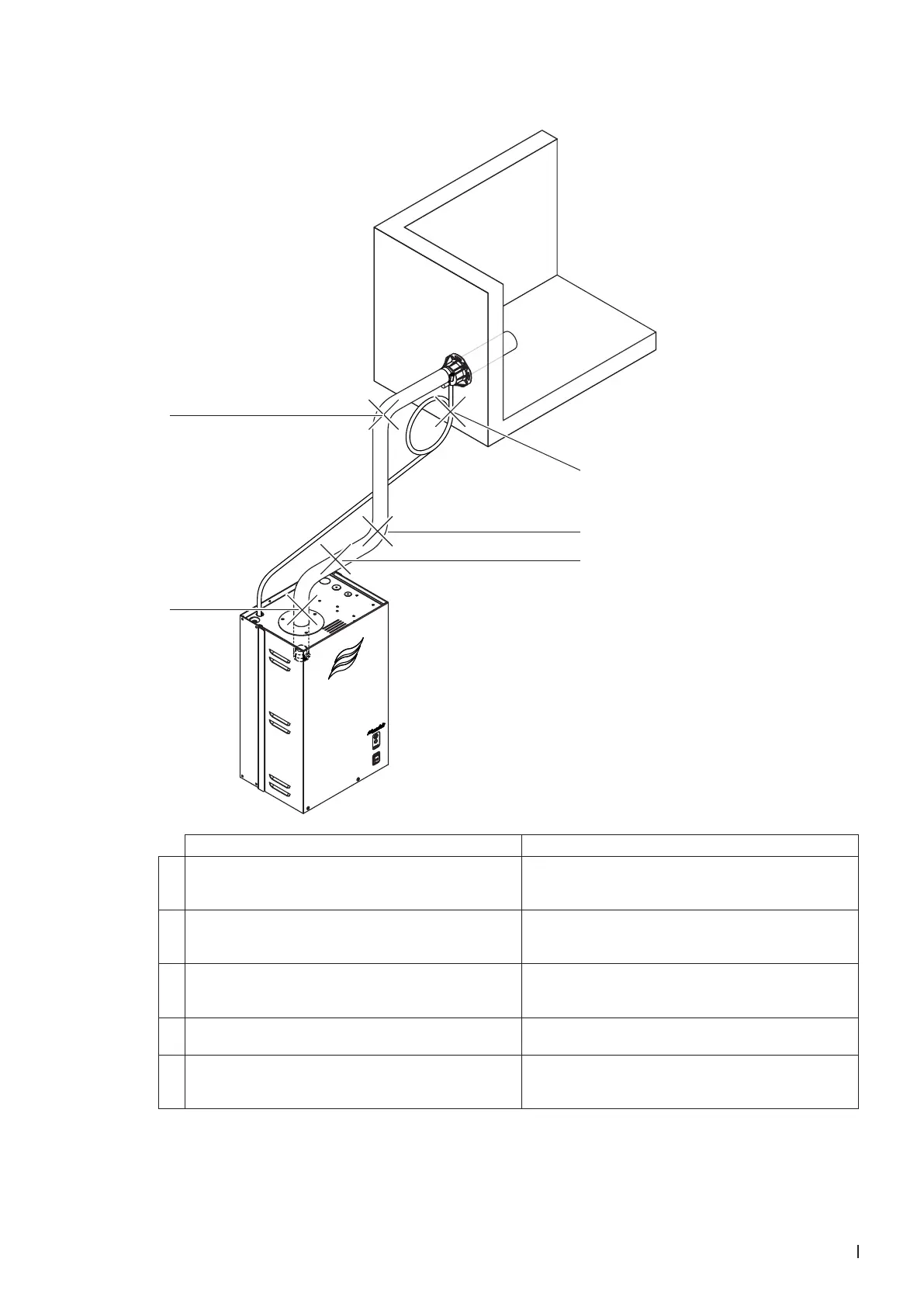

35Mounting and installation work

5.4.4 Common steam and condensate line errors

Wrong Correct

1

Steam hose/steam hose piece not led at least 300 mm perpen-

dicularly upwards before rst bend (forming of condensate).

Lead steam hose/steam hose piece at least 300 mm (for steam

hose installations) or 1,000 mm (for solid pipe installation)

perpendicularly upwards before rst bend.

2 Minimum bend radius of steam hose/solid steam line not

maintained (forming of condensate).

The minimum bend radius of 300 mm for steam hoses or

5 times steam line internal diameter for solid steam lines

must be maintained.

3 Condensate trap not sufciently high and installed too near

at the steam distributor.

The condensate trap must be at least 300 mm below the con-

nector on the steam distributor and it must have a minimum

height of 200 mm (ø200 mm).

4 No condensate trap installed at vertical transition. Install condensate trap at all low points and before vertical

transitions.

5 Steam line and condensate hose not sloped. Install steam line always with constant up or downslope

of min. 15 % (8.5°) and condensate hose with constant

downslope of min.15 % (8.5°).

Abb. 13: Common steam and condensate line errors

1

2

3

4

5

Loading...

Loading...