Parameter structure Keypad and display Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Performance

206 Mentor MP Advanced User Guide

www.controltechniques.com Issue Number: 4

6.2 CT Modbus RTU specification

This section describes the adaptation of the MODBUS RTU protocol offered on Control Techniques' products. The portable software class which

implements this protocol is also defined.

MODBUS RTU is a master slave system with half-duplex message exchange. The Control Techniques (CT) implementation supports the core

function codes to read and write registers. A scheme to map between MODBUS registers and CT parameters is defined. The CT implementation

also defines a 32bit extension to the standard 16bit register data format.

6.2.1 MODBUS RTU

Physical layer

RTU framing

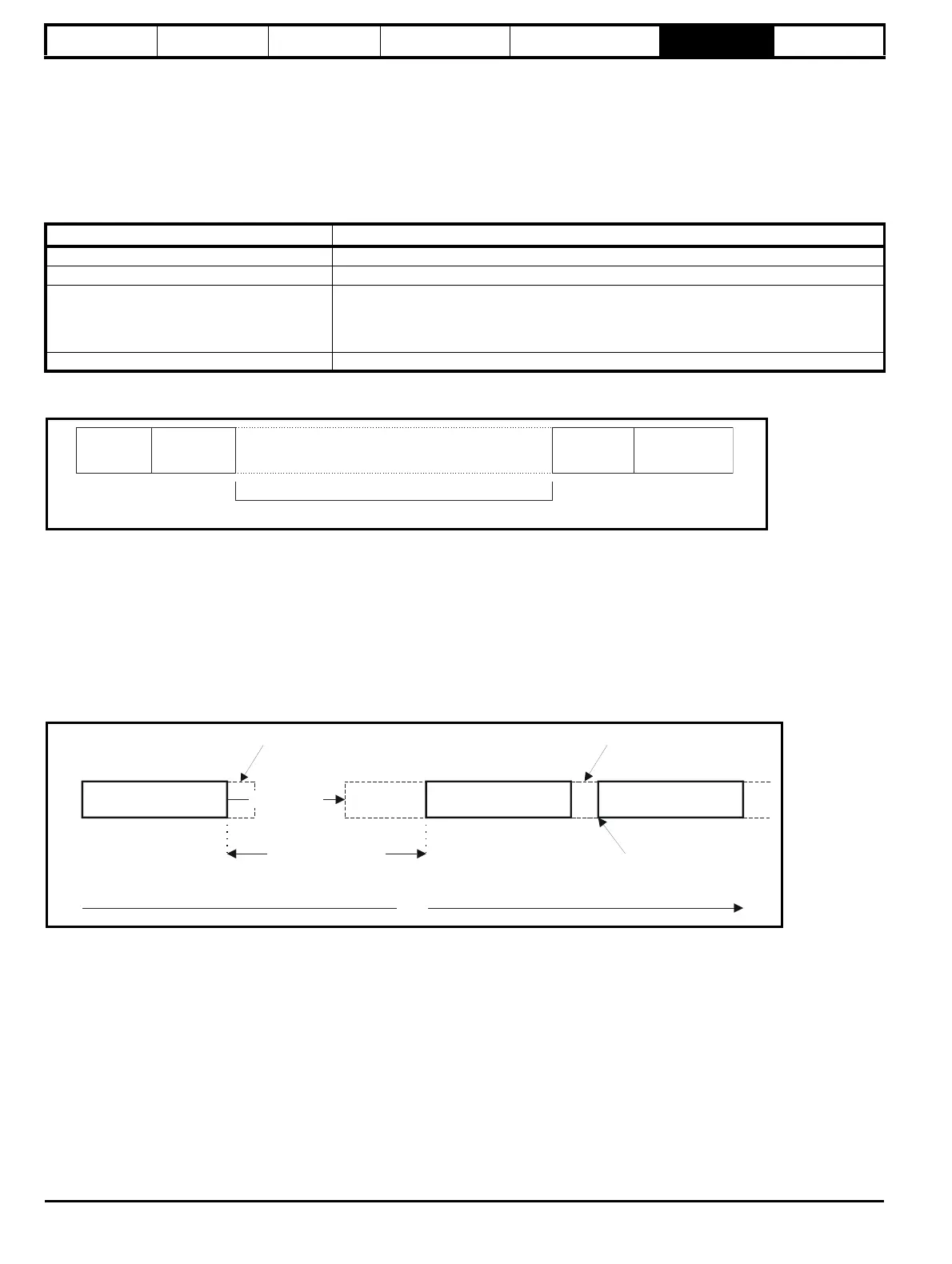

The frame has the following basic format

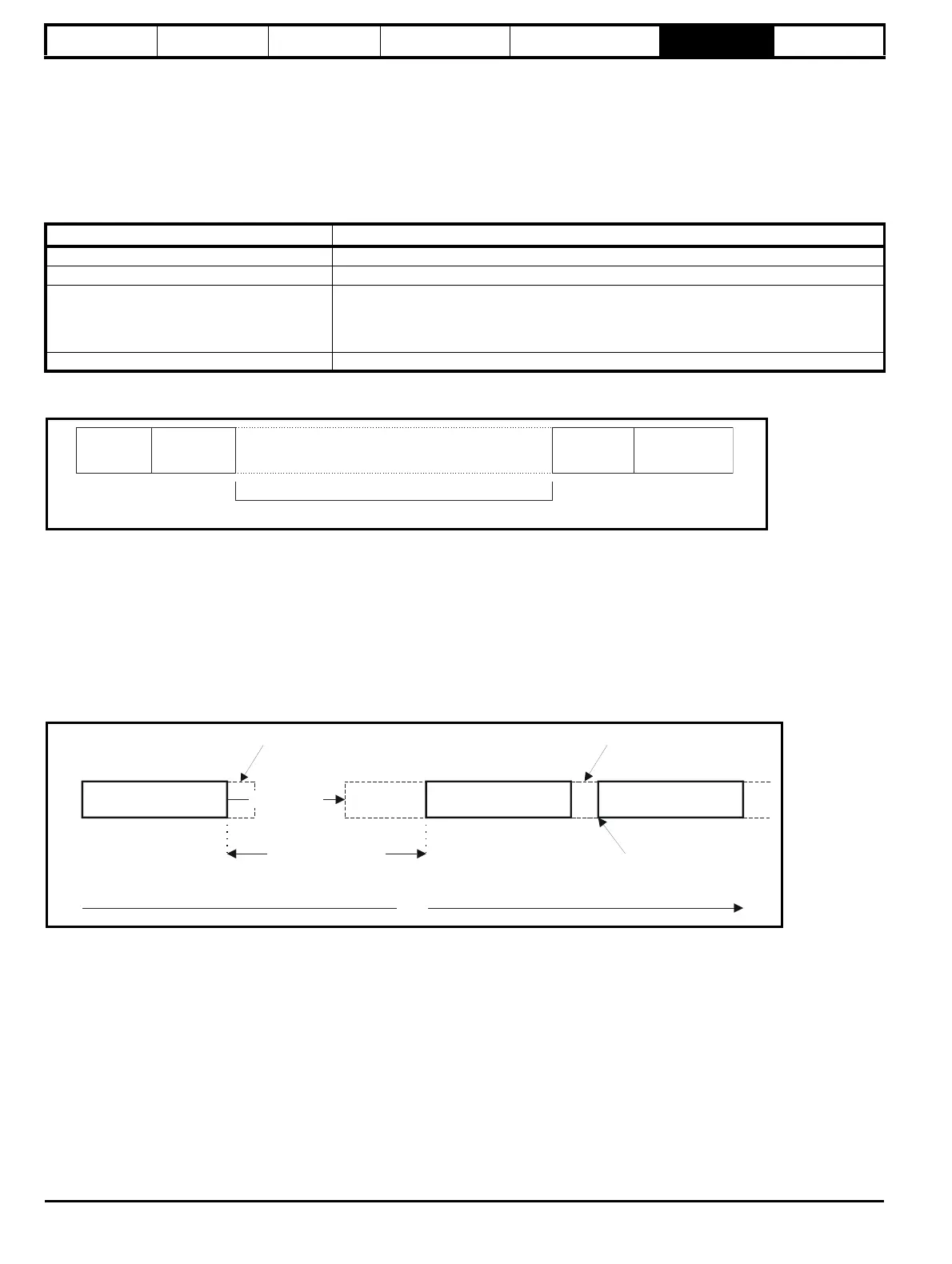

The frame is terminated with a minimum silent period of 3.5 character times (for example, at 19200 baud the minimum silent period is 2 ms).

Nodes use the terminating silence period to detect the end of frame and begin frame processing. All frames must therefore be transmitted as a

continuous stream without any gaps greater or equal to the silence period. If an erroneous gap is inserted then receiving nodes may start frame

processing early in which case the CRC will fail and the frame will be discarded.

MODBUS RTU is a master slave system. All master requests, except broadcast requests, will lead to a response from an individual slave. The

slave will respond (i.e. start transmitting the response) within the quoted maximum slave response time (this time is quoted in the data sheet for all

Control Techniques products). The minimum slave response time is also quoted but will never be less that the minimum silent period defined by

3.5 character times.

If the master request was a broadcast request then the master may transmit a new request once the maximum slave response time has expired.

The master must implement a message time out to handle transmission errors. This time out period must be set to the maximum slave response

time + transmission time for the response.

Attribute Description

Normal physical layer for multi-drop operation EIA485 2 wire

Bit stream Standard UART asynchronous symbols with Non Return to Zero (NRZ)

Symbol

Each symbol consists of:-

1 start bit

8 data bits (transmitted least significant bit first)

2 stop bits

Baud rates 300, 600, 1200,2400,4800, 9600, 19200, 38400, 57600, 115200

message data

FUNCTION

CODE

Silent

interval

Master request

Time

frame detect

Slave frame

processing

Slave response

Slave response time

Master request

New master request

can start here

minimum silence

period

minimum silence

period

Loading...

Loading...