Parameter structure Keypad and display Parameter x.00

Parameter description

format

Advanced parameter

descriptions

Serial comms

protocol

Performance

Mentor MP Advanced User Guide 15

Issue Number: 4 www.controltechniques.com

3 Parameter x.00

Parameter x.00 is available in all menus and has the following functions.

*These functions do not require a drive reset to become active. All other

functions require a drive reset.

3.1 Parameter x.00 reset

When an action is started by setting Pr x.00 to one of the above values

and initiating a drive reset this parameter is cleared when the action is

completed successfully. If the action is not started, e.g. because the

drive is enabled and an attempt is made to load defaults, etc., Pr x.00 is

not cleared and no trip is produced. If the action is started and then fails

for some reason a trip is always produced and Pr x.00 is not cleared.

It should be noted that parameter saves etc. can also be initiated with

the copying parameter (Pr 11.42 (SE09, 0.30)). If actions that can be

initiated by either parameter are started and then completed

successfully Pr x.00 is cleared and Pr 11.42 (SE09, 0.30) is cleared if it

has a value of less than 3.

It should be noted that there could be some conflict between the actions

of Pr x.00 and Pr 11.42 (SE09, 0.30) Parameter copying when the drive

is reset. If Pr 11.42 (SE09, 0.30) has a value of 1 or 2 and a valid action

is required from the value of Pr x.00 then only the action required by

Pr x.00 is performed. Pr x.00 and Pr 11.42 (SE09, 0.30) are then reset to

zero. If Pr 11.42 (SE09, 0.30) has a value of 3 or 4 it will operate

correctly causing parameters to be save to a SMARTCARD each time a

parameter save is performed.

3.2 Saving parameters in drive EEPROM

Drive parameters are saved to drive EEPROM by setting Pr x.00 to save

and initiating a drive reset. In addition to user save parameters. power

down save parameters are also saved by these actions and by changing

drive mode, but not by any other actions that result in parameters being

saved to drive EEPROM (i.e. loading defaults). Power down save

parameters are not saved at power down unless the drive is supplied

from a normal line power supply, and so this gives the user the option of

saving these parameters when required.

When the parameter save is complete Pr x.00 is reset to zero by the

drive. Care should be taken when saving parameters because this

action can take between 400 ms and several seconds depending on

how many changes are stored in the EEPROM. If the drive is powered

down during a parameter save, it is possible that data may be lost.

When the drive is operating from a normal line power supply then it will

stay active for a short time after the power is removed, however, if the

drive is being powered from a 24 V control supply, or it is being operated

from a low voltage battery supply, the drive will power down very quickly

after the supply is removed. The drive provides two features to reduce

the risk of data loss when the drive is powered down.

1. If Pr x.00 is set to save a parameter save is only initiated on drive

reset if the drive is supplied from a normal line power supply

(Pr 10.16 = 0 and Pr 6.44 = 0).

2. Two banks of arrays are provided in EEPROM to store the data.

When a parameter save is initiated the data is stored in a new bank

and only when the data store is complete does the new bank

become active. If the power is removed before the parameter save is

complete a SAVE.Er trip (user save parameter save error) or

PSAVE.Er trip (power down save parameter save error) will be

produced when the drive is powered up again indicating that the

drive has reverted to the data that was saved prior to the last

parameter save.

The second feature will significantly reduce the possibility of completely

invalidating all saved data, which would result in an EEF trip on the next

power-up. However the following points should be noted:

1. If the power is removed during a parameter save the current data

that is being saved to the EEPROM that is different from the last

data saved in the EEPROM will be lost and SAVE.Er or PSAVE.Er

trip will occur on power-up.

2. This feature does not apply when user save parameters are saved

automatically by adjusting the values in menu 0 with an LED keypad.

However, the time taken to save parameters in this way is very short,

and is unlikely to cause data loss if the power is removed after the

parameter has been changed. It should be noted that any parameter

changes made in this way are included in the currently active bank in

the EEPROM, so that if the power is removed during a subsequent

save initiated via Pr x.00 that results in an SAVE.Er trip, the changes

made via menu 0 will be retained and not lost.

3. User save parameters are saved to drive EEPROM after a transfer

of data from an electronic nameplate in an encoder.

4. User save parameters are saved to drive EEPROM after a transfer

of data from a SMARTCARD.

5. This feature is not provided for data saved to a SMARTCARD, and

so it is possible to corrupt the data files on a SMARTCARD if the

power is removed when data is being transferred to the card.

6. User save parameters are saved to drive EEPROM after defaults

are loaded.

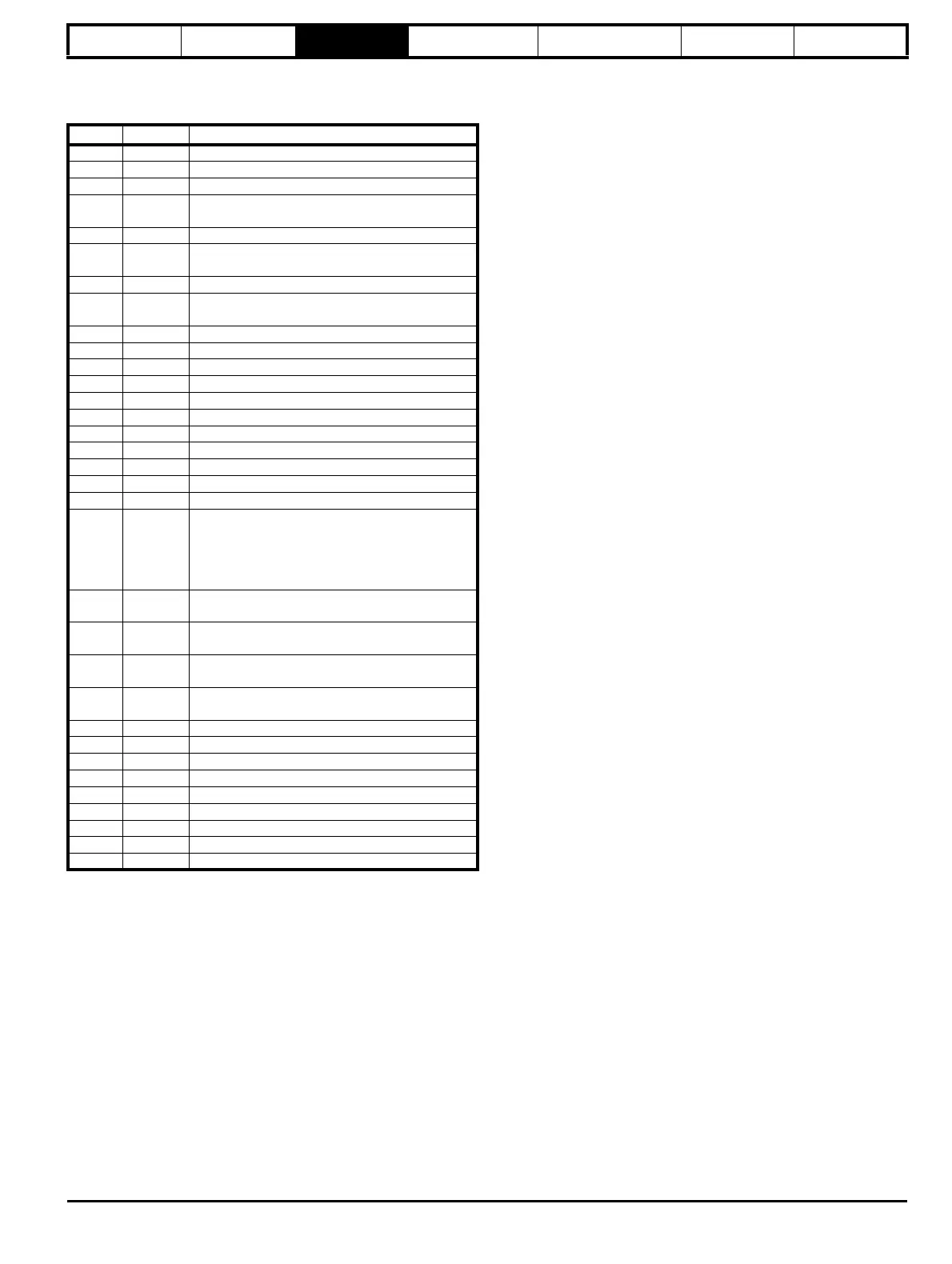

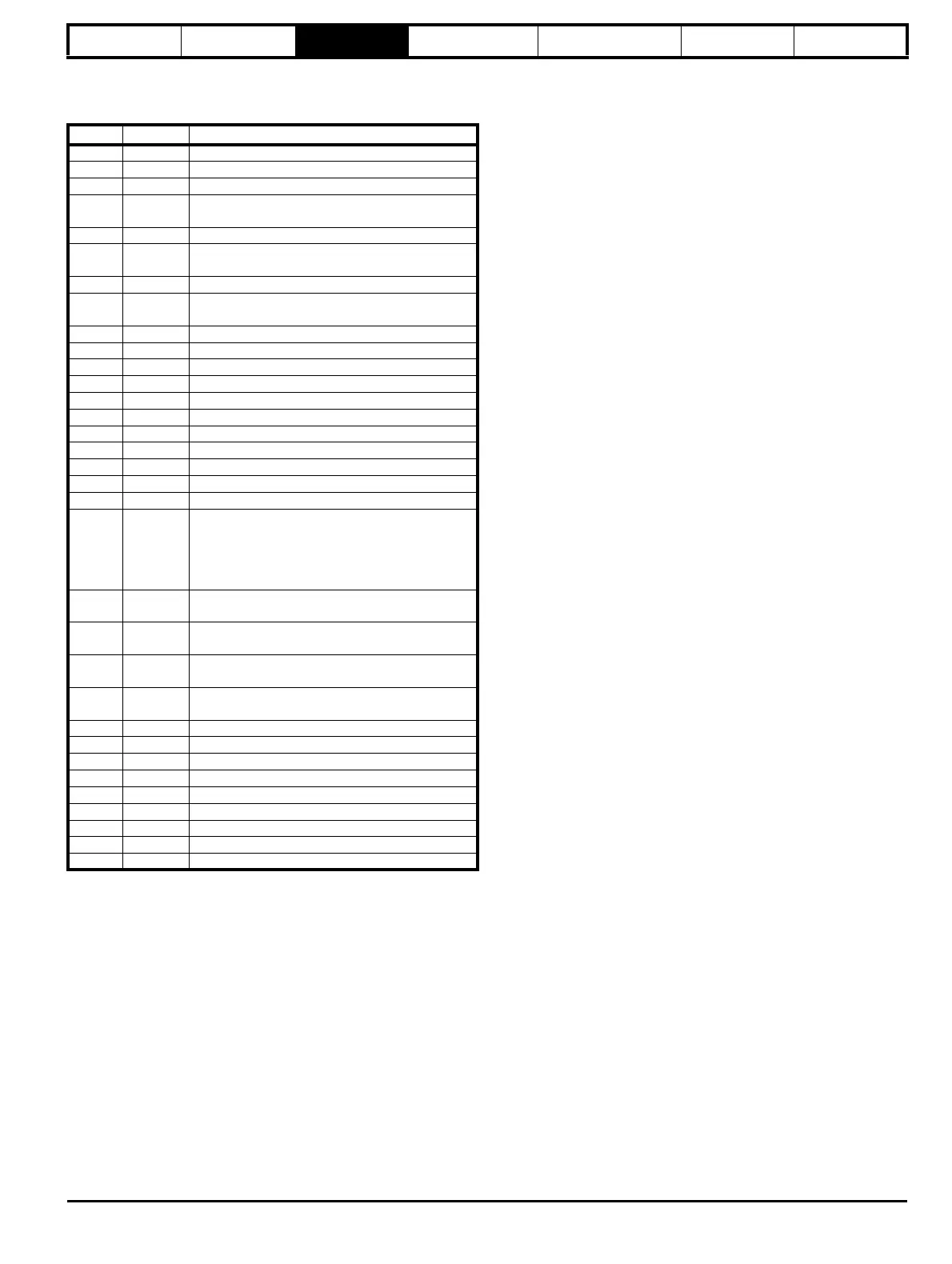

Value String Action

0 No Act No action

1 SAUE Save parameters

2 rEAd 1* Transfer SMARTCARD data block 1 to the drive

3PrOg 1*

Transfer drive parameters as difference from

default to SMARTCARD block number 1

4 rEAd 2* Transfer SMARTCARD data block 2 to the drive

5PrOg 2*

Transfer drive parameters as difference from

default to SMARTCARD block number 2

6 rEAd 3* Transfer SMARTCARD data block 3 to the drive

7PrOg 3*

Transfer drive parameters as difference from

default to SMARTCARD block number 3

8 diS.diFF Display non-default values only

9 diS.dESt Display destination parameters only

10 Eur Load European defaults

11 USA Load USA defaults

12 rES OP Reset all Solution Modules

1000 1000 Save parameters

1070 1070 Reset all Solution Modules

1233 1233 Load European defaults

1244 1244 Load USA defaults

1255 1255 Load European defaults (excluding menus 15 to 20)

1256 1256 Load USA defaults (excluding menus 15 to 20)

2001 2001*

Transfer drive parameter to a card and create a

bootable difference from default SMARTCARD

block with data block number 1 and clear

parameter 11.42. If data block 1 exists it is over

written.

3yyy 3yyy*

Transfer drive parameters to SMARTCARD block

number yyy

4yyy 4yyy*

Transfer drive parameters as difference from

default to SMARTCARD block number yyy

5yyy 5yyy*

Transfer Onboard Applications Lite ladder

program to SMARTCARD block number yyy

6yyy 6yyy*

Transfer SMARTCARD data block yyy to the

drive

7yyy 7yyy* Erase SMARTCARD data block yyy

8yyy 8yyy* Compare drive data with SMARTCARD block yyy

9555 9555* Clear SMARTCARD warning suppression flag

9666 9666* Set SMARTCARD warning suppression flag

9777 9777* Clear SMARTCARD read-only flag

9888 9888* Set SMARTCARD read-only flag

9999 9999* Erase SMARTCARD

12000** 12000** Display non-default values only

12001** 12001** Display destination parameters only

Loading...

Loading...