•

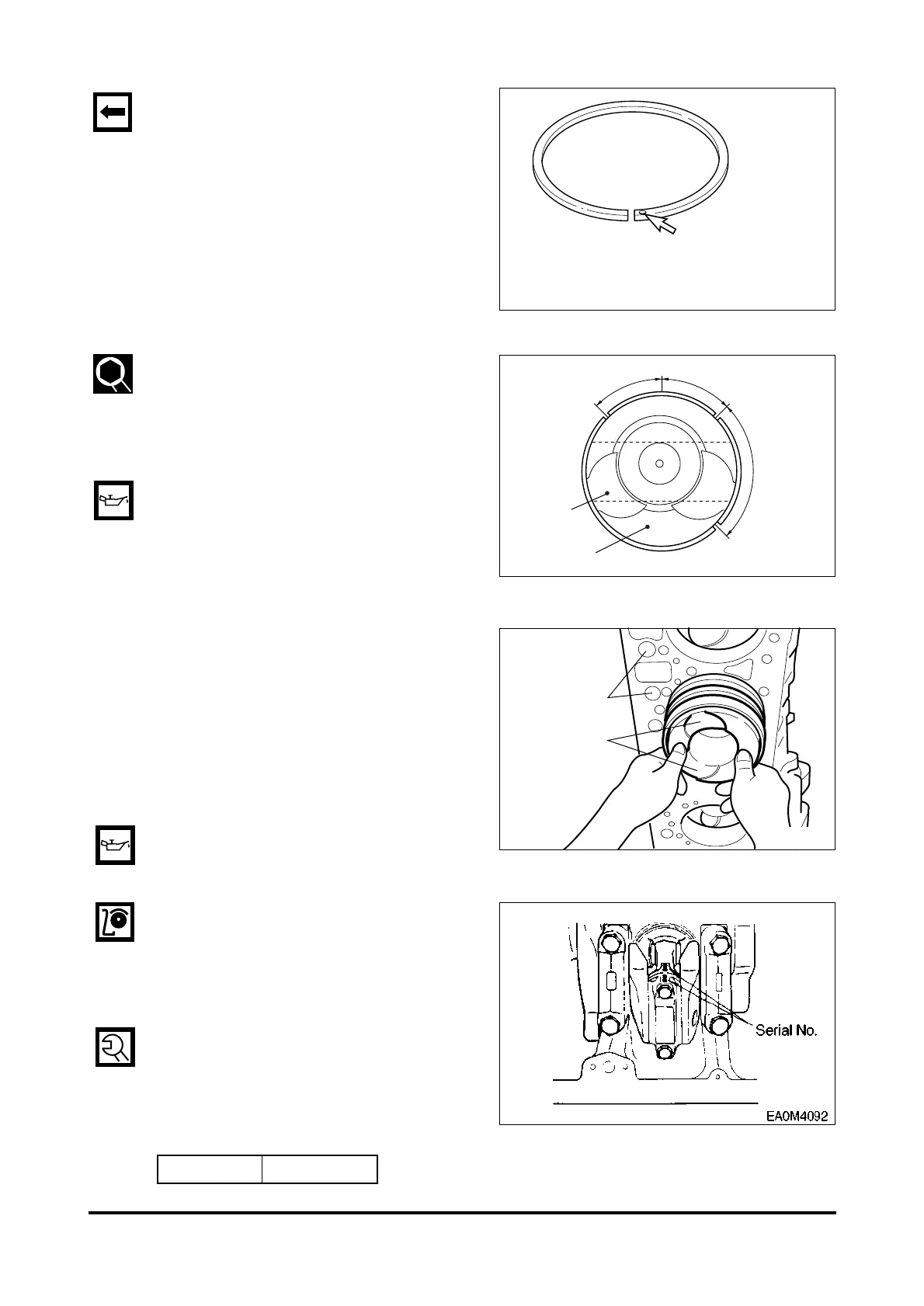

Identify the mark “Y” or “TOP” on the

ring end to prevent the top and bottom

of the piston ring from being inter-

changed and make the marked por-

tion face upward.

•

Adjust the angle among individual pis-

ton ring gaps to 90˚ and fit a piston

assembling jig onto the piston, Use

care not to match the ring gaps with

the pin direction.

•

Install the bearing by aligning it with

the connecting rod key groove and

apply oil to the bearing and piston.

•

Position the valve seating surface

toward the tappet hole and insert the

piston with hand.

Use care not to damage the cylinder

liner and piston, and slightly lift and

insert the piston into the cylinder so

that the ring may not be damaged by

the fillet of the liner.

•

Install the bearing in the connecting

rod cap and apply oil.

•

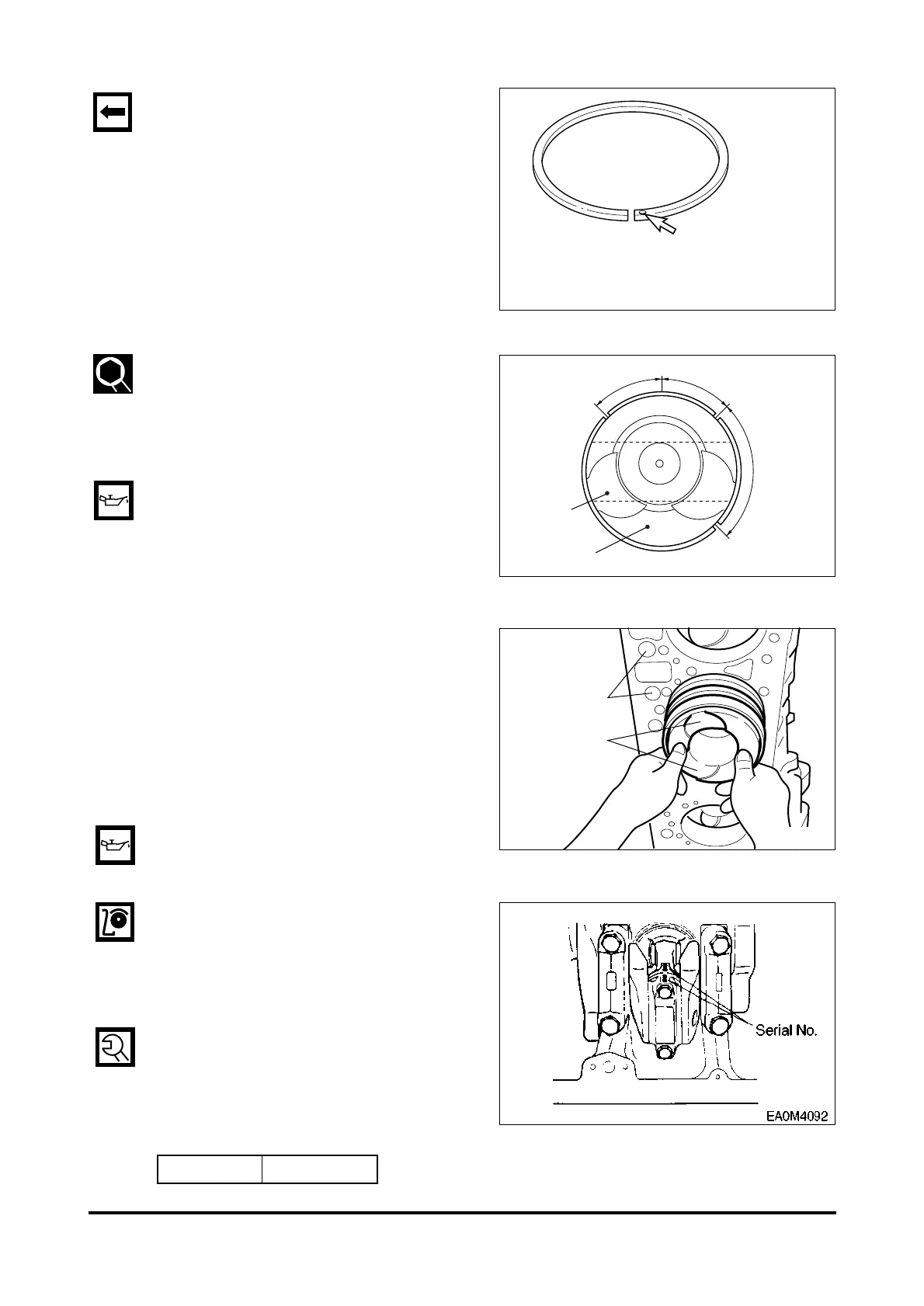

Make sure that the manufacture serial

numbers impressed on the connecting

rod cap and connecting rod big end are

identical, and install the connecting rod

cap by aligning it with dowel pin.

•

Wet the fixing bolts with oil, semi-tight-

en them with hand, tighten them to 15

kg.m for 1st stage and 22 kg.m for 2nd

stage respectively, and finally to spec-

ified torque.

- 84 -

REASSEMBLY

Loading...

Loading...