Function:

In addition to its normal function, this parameter can

be used for two different tests.

Furthermore, it is possible to reset to the default factory

settings for all Setups, except parameters 500 Ad-

dress, 501 Baud rate, 600-605 Operating data and

615-617 Fault log.

Description of choice:

Normal function [0] is used for normal operation of the

motor.

Function with de-activated inverter [1] is selected if

control is desired over the influence of the control sig-

nal on the control card and its functions - without the

motor shaft running.

Control card [2] is selected if control of the analogue

and digital inputs, analogue and digital outputs, relay

outputs and the control voltage of +10 V is desired.

A test connector with internal connections is required

for this test.

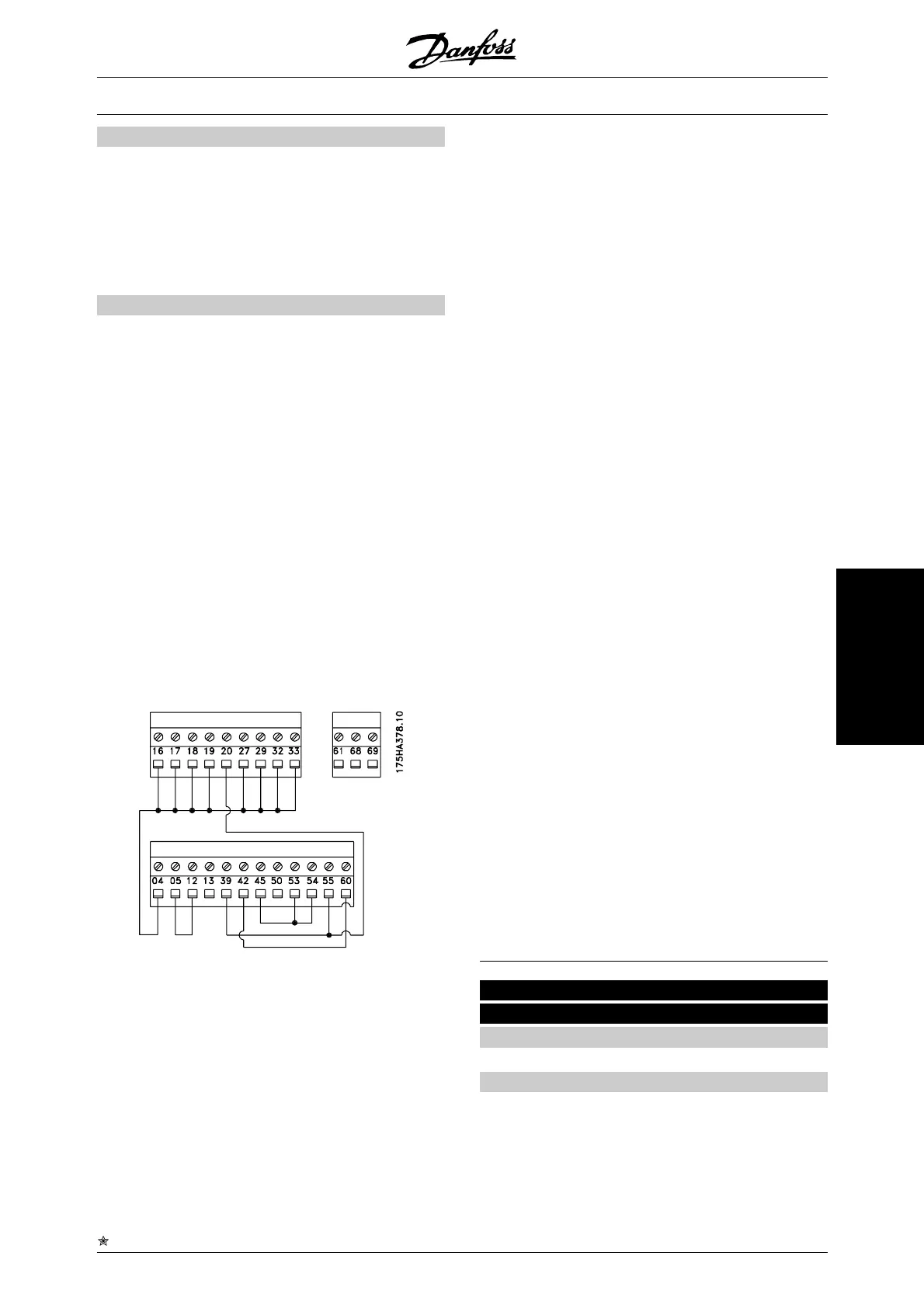

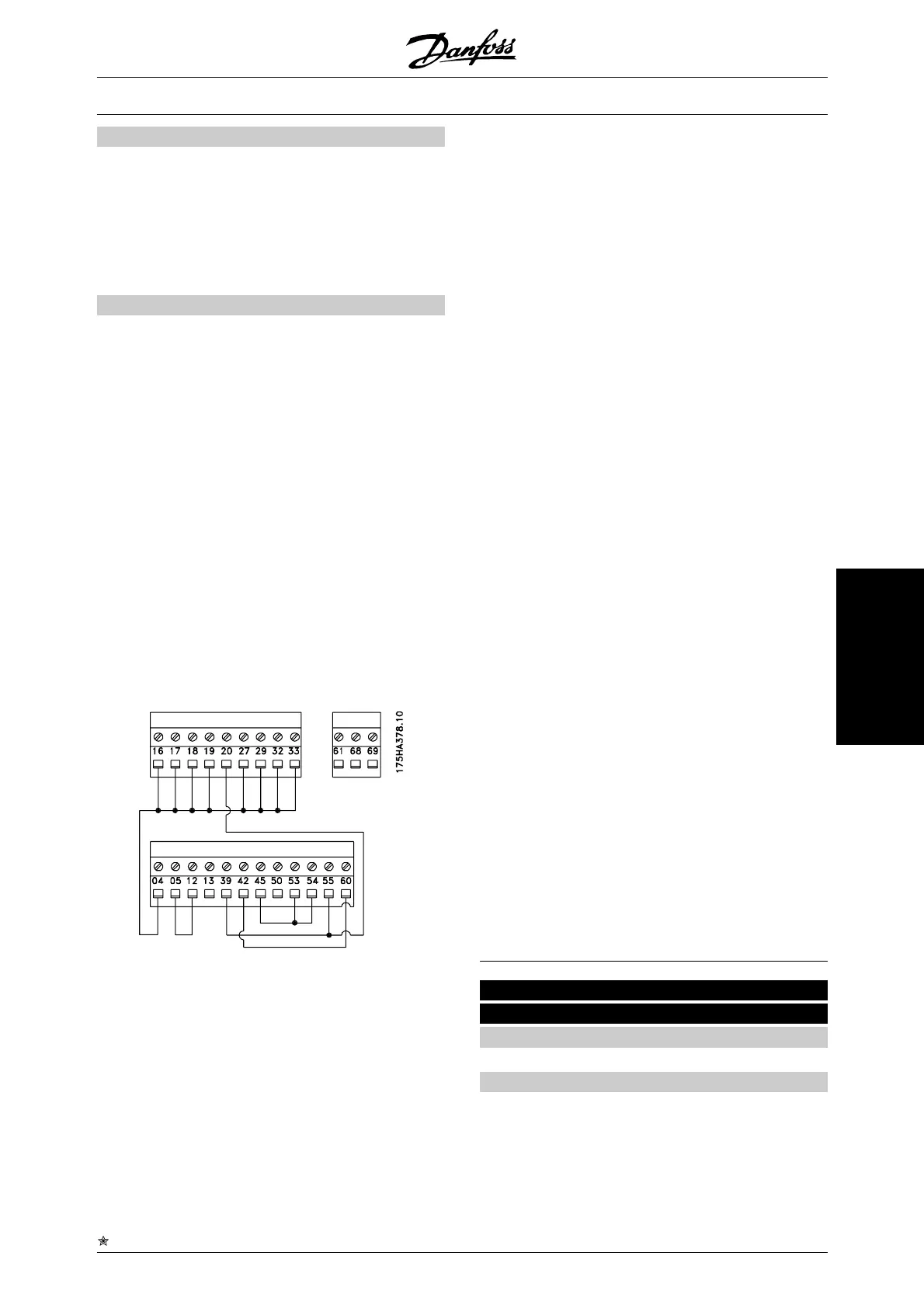

The test connector for the Control card [2] is set up as

follows:

connect 4-16-17-18-19-27-29-32-33;

connect 5-12;

connect 39-20-55;

connect 42 - 60;

connect 45-53-54.

Use the following procedure for the control card test:

1.

Select Control card test.

2. Cut off the mains supply and wait for the light

in the display to go out.

3. Insert the test plug (see preceding column).

4. Connect to mains.

5. The frequency converter expects the [OK]

key to be pressed (the test cannot be run

without LCP).

6. The frequency converter automatically tests

the control card.

7. Remove the test connector and press the

[OK] key when the frequency converter dis-

plays "TEST COMPLETED".

8.

Parameter 620 Operating mode is automati-

cally set to Normal function.

If the control card test fails, the frequency conver-ter

will display "TEST FAILED". Replace the control card.

Initialisation [3] is selected if the factory setting of the

unit is to be generated without resetting parameters

500 Address, 501 Baud rate, 600-605 Operating data

and 615-6171 Fault log.

Procedure for initialisation:

1.

Select Initialisation.

2. Press the [OK] key.

3. Cut off the mains supply and wait for the light

in the display to go out.

4. Connect to mains.

5. Initialisation of all parameters will be carried

out in all Setups with the exception of param-

eters 500 Address, 501 Baud rate, 600-605

Operating data and 615-617 Fault log.

Manual initialisation is another option. (See Manual

initialisation).

655 Fault log: Real time

(F. LOG REAL TIME)

Value:

[Index 1-10] Value: 000000.0000 - 991231.2359

Function:

This parameter has a similar function as parameter

616. Only here the log is based on the real time clock,

not running hours from zero. This means a date and

time are shown.

VLT

®

6000 HVAC Series

= factory setting, () = display text, [] = value for use in communication via serial communication port

MG.61.B5.02 - VLT

®

is a registered Danfoss trademark 179

Programming

Loading...

Loading...