5.9 Advanced Minimum Speed Monitoring

Overview

Some pumps are sensitive to operating at low speed.

Insucient cooling or lubrication at low speed are typical

reasons.

Under overload conditions, the drive protects itself using

its integral protection features, which include lowering the

speed. For example, the current limit controller can lower

the speed. Sometimes, the speed can go lower than the

speed specied in parameter 4-11 Motor Speed Low Limit

[RPM] and parameter 4-12 Motor Speed Low Limit [Hz].

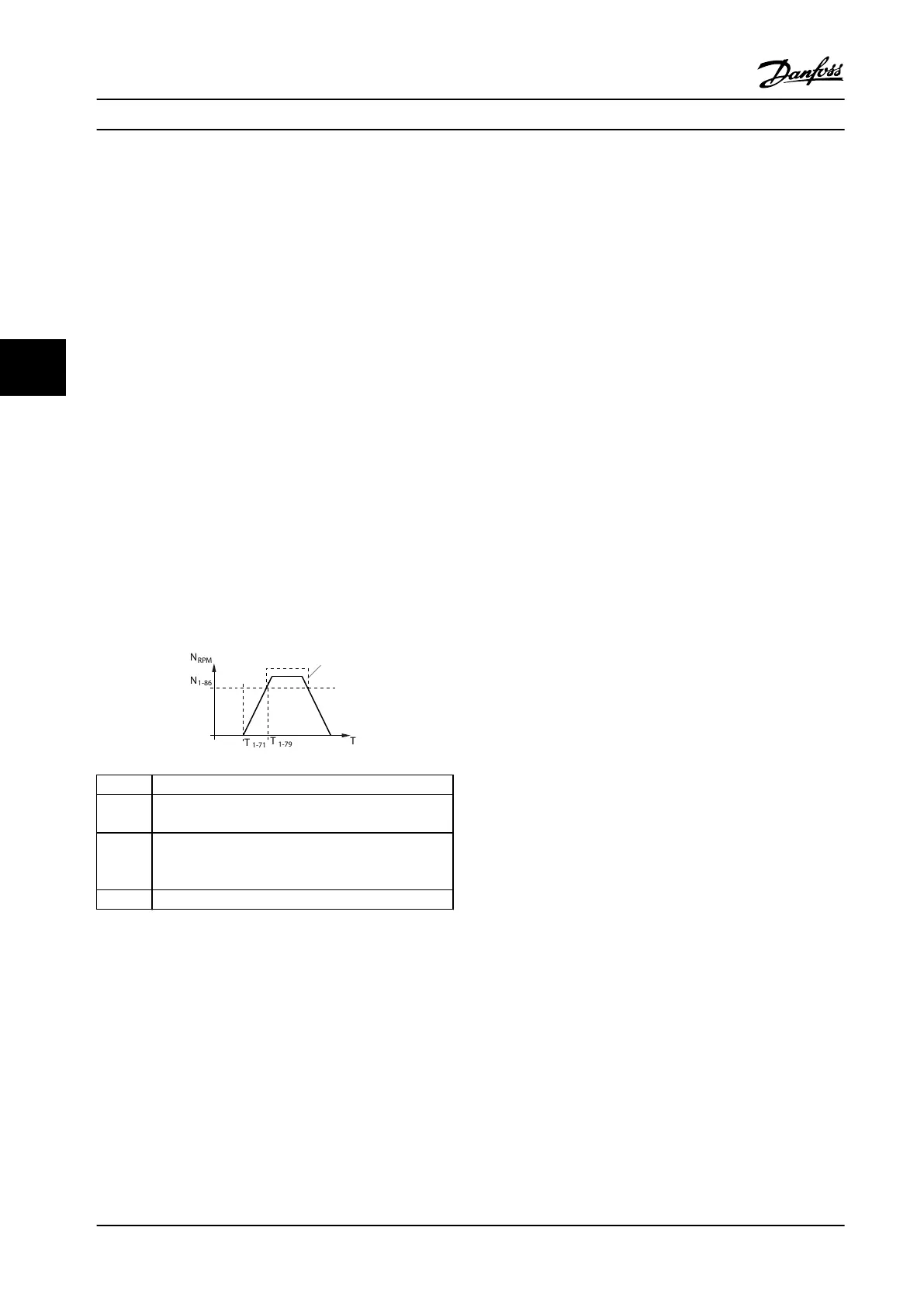

If the speed drops below a certain value, the advanced

minimum-speed monitoring feature trips the drive. If the

pump motor does not reach the speed specied in

parameter 1-86 Trip Speed Low [RPM] within the time

specied in parameter 1-79 Pump Start Max Time to Trip

(ramping up takes too long), the drive trips. Timers for

parameter 1-71 Start Delay and parameter 1-79 Pump Start

Max Time to Trip start at the same time when the start

command is issued. For example, if the value in

parameter 1-71 Start Delay is more than or equal to the

value in parameter 1-79 Pump Start Max Time to Trip, the

drive never starts.

T

1-71

Parameter 1-71 Start Delay.

T

1-79

Parameter 1-79 Pump Start Max Time to Trip. This time

includes the time in T

1-71

.

N

1-86

Parameter 1-86 Trip Speed Low [RPM]. If the speed

drops below this value during normal operation, the

drive trips.

1 Normal operation.

Figure 5.15 Advanced Minimum Speed Monitoring

5.10 Dynamic Braking Overview

Dynamic braking slows the motor using 1 of the following

methods:

•

AC brake

The brake energy is distributed in the motor by

changing the loss conditions in the motor

(parameter 2-10 Brake Function = [2]). The AC

brake function cannot be used in applications

with high cycling frequency since this situation

overheats the motor.

•

DC brake

An overmodulated DC current added to the AC

current works as an eddy current brake

(parameter 2-02 DC Braking Time ≠ 0 s).

•

Resistor brake

A brake IGBT keeps the overvoltage under a

certain threshold by directing the brake energy

from the motor to the connected brake resistor

(parameter 2-10 Brake Function = [1]). For more

information on selecting a brake resistor, see VLT

®

Brake Resistor MCE 101 Design Guide.

For drives equipped with the brake option, a brake IGBT

along with terminals 81(R-) and 82(R+) are included for

connecting an external brake resistor.

The function of the brake IGBT is to limit the voltage in the

DC link whenever the maximum voltage limit is exceeded.

It limits the voltage by switching the externally mounted

resistor across the DC bus to remove excess DC voltage

present on the bus capacitors.

External brake resistor placement has the advantages of

selecting the resistor based on application need,

dissipating the energy outside of the control panel, and

protecting the drive from overheating if the brake resistor

is overloaded.

The brake IGBT gate signal originates on the control card

and is delivered to the brake IGBT via the power card and

gatedrive card. Also, the power and control cards monitor

the brake IGBT for a short circuit. The power card also

monitors the brake resistor for overloads.

Product Features

VLT

®

AQUA Drive FC 202

32 Danfoss A/S © 01/2018 All rights reserved. MG22B222

55

Loading...

Loading...