10.11 Eciency

Eciency of the drive (η

VLT

)

The load on the drive has little eect on its eciency. In

general, the eciency is the same at the rated motor

frequency f

M,N

, whether the motor supplies 100% of the

rated shaft torque or only 75%, in case of part loads.

The eciency of the drive does not change even if other

U/f characteristics are selected. However, the U/f character-

istics inuence the eciency of the motor.

The eciency declines slightly when the switching

frequency is set to a value of above 5 kHz. The eciency is

slightly reduced when the mains voltage is 480 V, or if the

motor cable is longer than 30 m (98 ft).

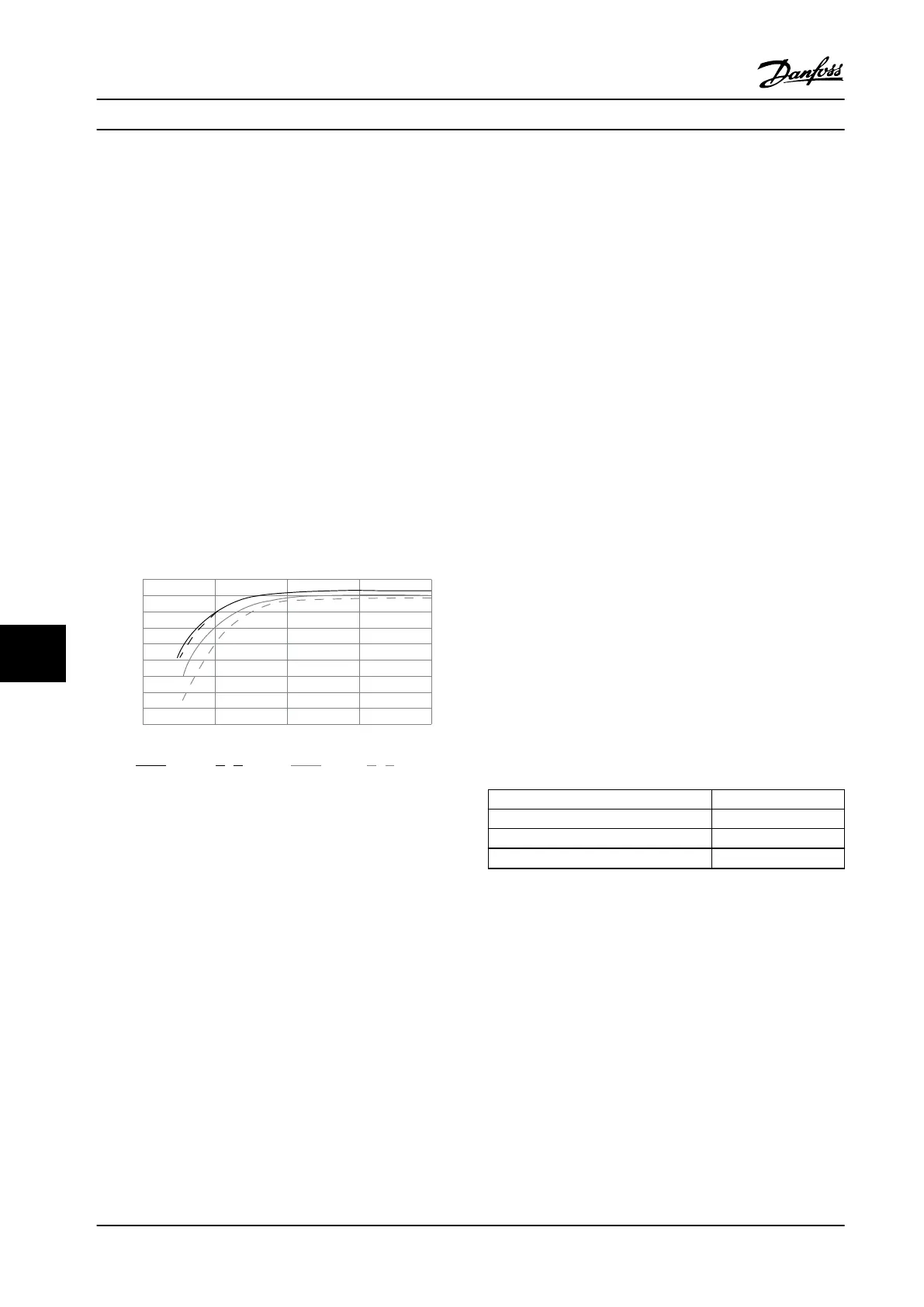

Drive eciency calculation

Calculate the eciency of the drive at dierent speeds and

loads based on Figure 10.16. The factor in this graph must

be multiplied with the specic eciency factor listed in the

specication tables in chapter 7.1 Electrical Data, 380–480 V

and chapter 7.2 Electrical Data, 525–690 V .

1.0

0.99

0.98

0.97

0.96

0.95

0.93

0.92

0% 50% 100% 200%

0.94

Relative Eciency

130BB252.11

1.01

150%

% Speed

100% load 75% load 50% load 25% load

Figure 10.16 Typical Eciency Curves

Example: Assume a 160 kW, 380–480 V AC drive at 25%

load at 50% speed. Figure 10.16 shows 0.97 - rated

eciency for a 160 kW drive is 0.98. The actual eciency is

then: 0.97x 0.98=0.95.

Eciency of the motor (η

MOTOR)

The eciency of a motor connected to the drive depends

on magnetizing level. In general, the eciency is as good

as with mains operation. The eciency of the motor

depends on the type of motor.

In the range of 75–100% of the rated torque, the eciency

of the motor is practically constant, both when the drive

controls it and when it runs directly on the mains.

In small motors, the inuence from the U/f characteristic

on eciency is marginal. However, in motors from 11 kW

(14.75 hp) and up, the advantages are signicant.

Typically the switching frequency does not aect the

eciency of small motors. Motors from 11 kW (14.75 hp)

and up have their eciency improved (1–2%) because the

shape of the motor current sine-wave is almost perfect at

high switching frequency.

Eciency of the system (η

SYSTEM

)

To calculate system eciency, the eciency of the drive

(η

VLT

) is multiplied by the eciency of the motor (η

MOTOR

):

η

SYSTEM

=η

VLT

x η

MOTOR

10.12 Acoustic Noise

The acoustic noise from the drive comes from 3 sources:

•

DC intermediate circuit coils.

•

Internal fans.

•

RFI

lter choke.

Table 10.24 lists the typical acoustic noise values measured

at a distance of 1 m (9 ft) from the unit.

Enclosure size dBA at full fan speed

D1h/D3h/D5h/D6h 73

D2h/D4h/D7h/D8h 75

E1h–E4h 80

Table 10.24 Acoustic Noise

Test results performed according to ISO 3744 for audible

noise magnitude in a controlled environment. Noise tone

has been

quantied for engineering data record of

hardware performance per ISO 1996-2 Annex D.

A new fan control algorithm for E1h-E4h enlosure sizes

helps improve audible noise performance by allowing the

operator to select dierent fan operation modes based on

specic conditions. For more information, see

parameter 30-50 Heat Sink Fan Mode.

Electrical Installation Con...

VLT

®

AQUA Drive FC 202

172 Danfoss A/S © 01/2018 All rights reserved. MG22B222

1010

Loading...

Loading...