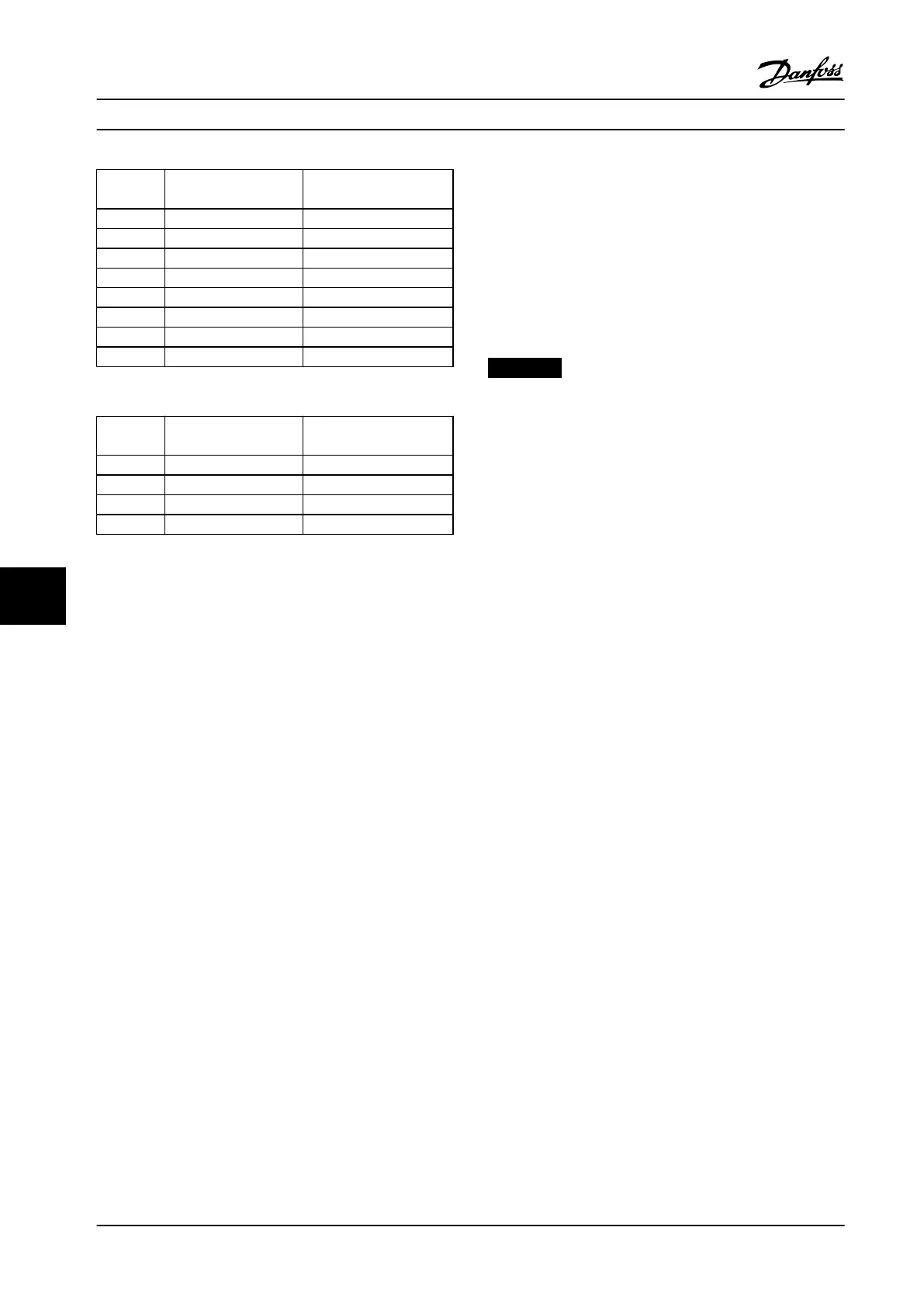

Frame Door fan/top fan

[m

3

/hr (cfm)]

Heat sink fan

[m

3

/hr (cfm)]

D1h 102 (60) 420 (250)

D2h 204 (120) 840 (500)

D3h 102 (60) 420 (250)

D4h 204 (120) 840 (500)

D5h 102 (60) 420 (250)

D6h 102 (60) 420 (250)

D7h 204 (120) 840 (500)

D8h 204 (120) 840 (500)

Table 9.2 D1h–D8h Airow Rate

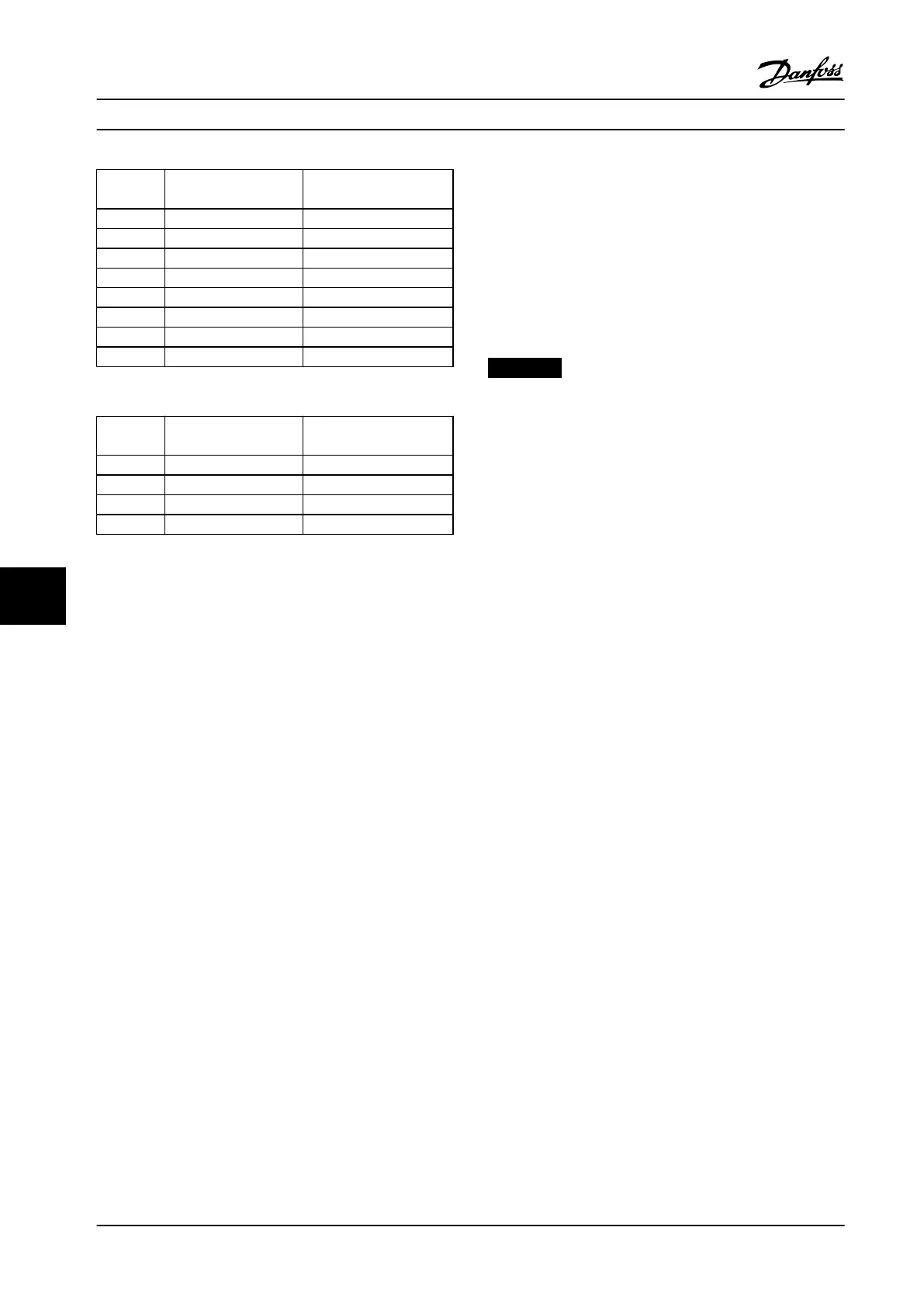

Frame Door fan/top fan

[m

3

/hr (cfm)]

Heat sink fan

[m

3

/hr (cfm)]

E1h 510 (300) 994 (585)

E2h 552 (325) 1053–1206 (620–710)

E3h 595 (350) 994 (585)

E4h 629 (370) 1053–1206 (620–710)

Table 9.3 E1h–E4h Airow Rate

9.6 Derating

Derating is a method used to reduce output current to

avoid tripping the drive when high temperatures are

reached within the enclosure. If certain extreme operating

conditions are expected, a higher-powered drive can be

selected to eliminate the need for derating. This is called

manual derating. Otherwise, the drive automatically

derates the output current to eliminate the excessive heat

generated by extreme conditions.

Manual derating

When the following conditions are present, Danfoss

recommends selecting a drive 1 power size higher (for

example P710 instead of P630):

•

Low-speed – continuous operation at low RPM in

constant torque applications.

•

Low air pressure – operating at altitudes above

1000 m (3281 ft).

•

High ambient temperature – operating at

ambient temperatures of 10 °C (50 °F).

•

High switching frequency.

•

Long motor cables.

•

Cables with a large cross-section.

Automatic derating

If the following operating conditions are found, the drive

automatically changes switching frequency or switching

pattern (PWM to SFAVM) to reduce excessive heat within

the enclosure:

•

High temperature on the control card or heat

sink.

•

High motor load or low motor speed.

•

High DC-link voltage.

NOTICE!

Automatic derating is dierent when

parameter 14-55 Output Filter is set to [2] Sine-Wave Filter

Fixed.

9.6.1 Derating for Low-Speed Operation

When a motor is connected to a drive, it is necessary to

check that the cooling of the motor is adequate. The level

of cooling required depends on the following:

•

Load on the motor.

•

Operating speed.

•

Length of operating time.

Constant torque applications

A problem can occur at low RPM values in constant torque

applications. In a constant torque application, a motor can

overheat at low speeds because less cooling air is being

provided by the fan within the motor.

If the motor is run continuously at an RPM value lower

than half of the rated value, the motor must be supplied

with extra air cooling. If extra air cooling cannot be

provided, a motor designed for low RPM/constant torque

applications can be used instead.

Variable (quadratic) torque applications

Extra cooling or derating of the motor is not required in

variable torque applications where the torque is propor-

tional to the square of the speed, and the power is

proportional to the cube of the speed. Centrifugal pumps

and fans are common variable torque applications.

Mechanical Installation Con...

VLT

®

AQUA Drive FC 202

152 Danfoss A/S © 01/2018 All rights reserved. MG22B222

99

Loading...

Loading...