If a derag is triggered from a drive-stopped state, the rst

o delay is skipped. The deragging event consists of

several cycles. One cycle consisting of 1 pulse in the

reverse direction followed by 1 pulse in the forward

direction. Deragging is considered nished after the

specied number of cycles have completed. More specif-

ically, on the last pulse (it is always forward) of the last

cycle, the derag is considered nished after the deragging

run-time expires (the drive is running at derag speed). In

between pulses, the drive output coasts for a specied o-

delay time to let debris in the pump settle.

NOTICE!

Do not enable deragging if the pump cannot operate in

reverse direction.

There are 3 dierent notications for an ongoing

deragging event:

•

Status in the LCP: Auto Remote Derag.

•

A bit in the extended status word

(bit 23, 80 0000 hex).

•

A digital output can be congured to reect the

active deragging status.

Depending on the application and the purpose of using it,

this feature can be used as a preventive or reactive

measure and can be triggered/started in the following

ways:

•

On each start command (parameter 29-11 Derag

at Start/Stop).

•

On each stop command (parameter 29-11 Derag

at Start/Stop).

•

On each start/stop command

(parameter 29-11 Derag at Start/Stop).

•

On digital input (parameter group 5-1* Digital

Inputs).

•

On drive action with the smart logic controller

(parameter 13-52 SL Controller Action).

•

As timed action (parameter group 23-** Time-

based Functions).

•

On high power (parameter group 29-2* Derag

Power Tuning).

5.7

Pre/post Lube Overview

Certain motors require lubrication of their mechanical parts

before and during running to prevent damage/wear. This

situation is especially the case when the motor has not

been running for extended periods of time. Pre-lube also

supports applications that require certain exhaust fans to

be running. The pre-lube feature signals an external device

to start performing a specic action for a user-dened

time, beginning at the rising edge of a run command (for

example, start request). Furthermore, a start delay

(parameter 1-71 Start Delay) can be entered such that the

pre-lube occurs only while the drive is stopped and the

pre-lube completes just before the drive starts to ramp up.

Pre-lube can also be congured such that the external

device remains signaled always when the drive is in a

running state, or such that the signal stays on after the

motor has stopped (parameter 29-42 Post Lube Time).

Application examples include a device to lubricate the

mechanical parts of a motor/pump or some type of

exhaust fan unit.

An example use case for a lubrication device would be to

start lubrication at the rising edge of a start request. Delay

the start for a time and stop lubrication when the delay

expires and the drive starts.

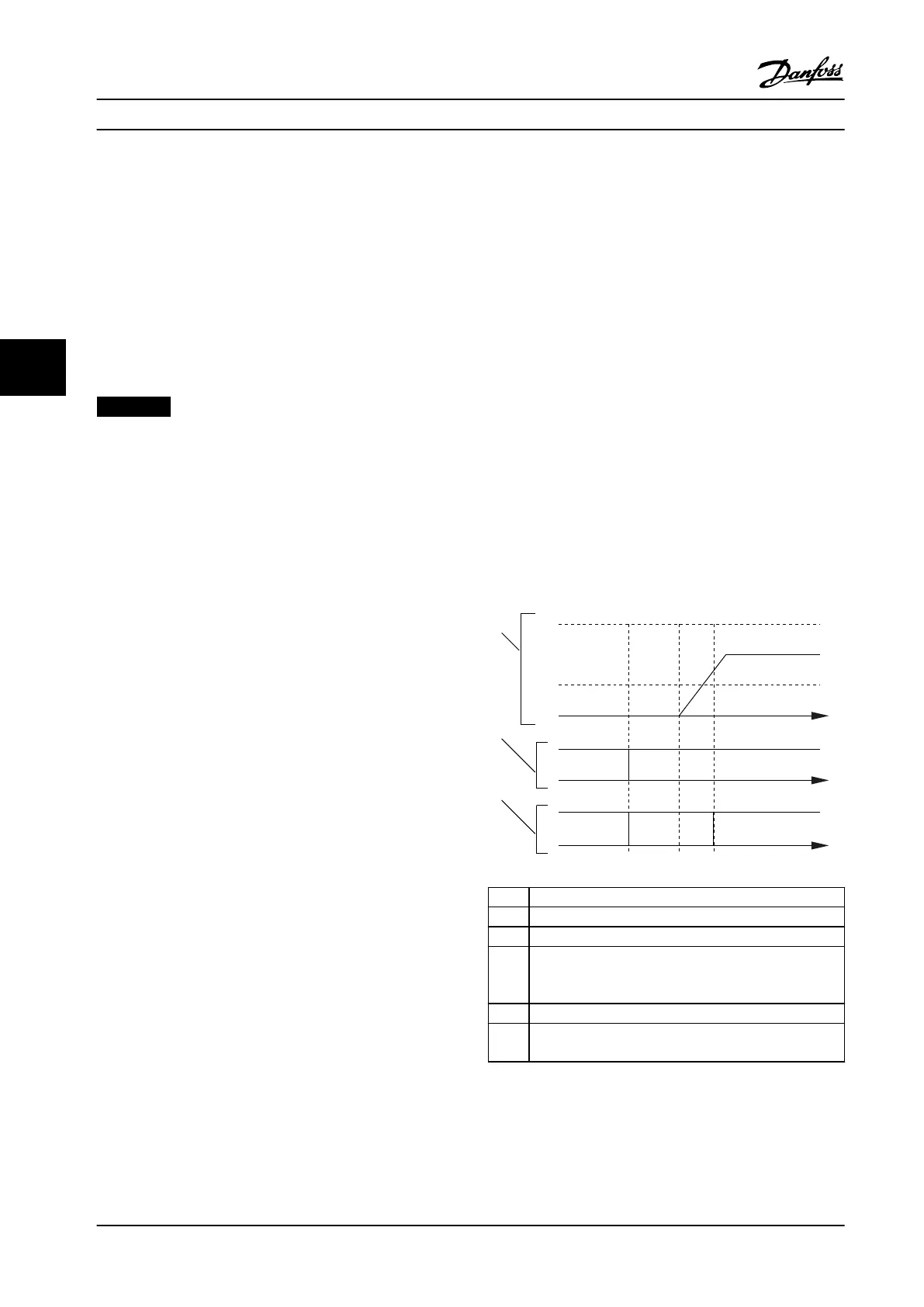

Figure 5.13 shows a

dierent usage of the feature. In this

case, the delay expires while the drive is already ramping

up. See the related parameters in Table 5.1.

130BD765.10

N

MAX

N

MIN

0

1

1

0

0

1

2

3

t1 t3t2

T

T

T

1 Speed curve.

2 Start command (for example, terminal 18).

3 Pre-lube output signal.

t

1

Start command issued (for example, terminal 18 is set

active). The start delay timer (parameter 1-71 Start Delay)

and the pre-lube timer (parameter 29-41 Pre Lube Time).

t

2

The start delay timer expires. The drive starts to ramp up.

t

3

The pre-lube timer (parameter 29-41 Pre Lube Time)

expires.

Figure 5.13 Pre/post Lube Function Example

Product Features

VLT

®

AQUA Drive FC 202

30 Danfoss A/S © 01/2018 All rights reserved. MG22B222

55

Loading...

Loading...