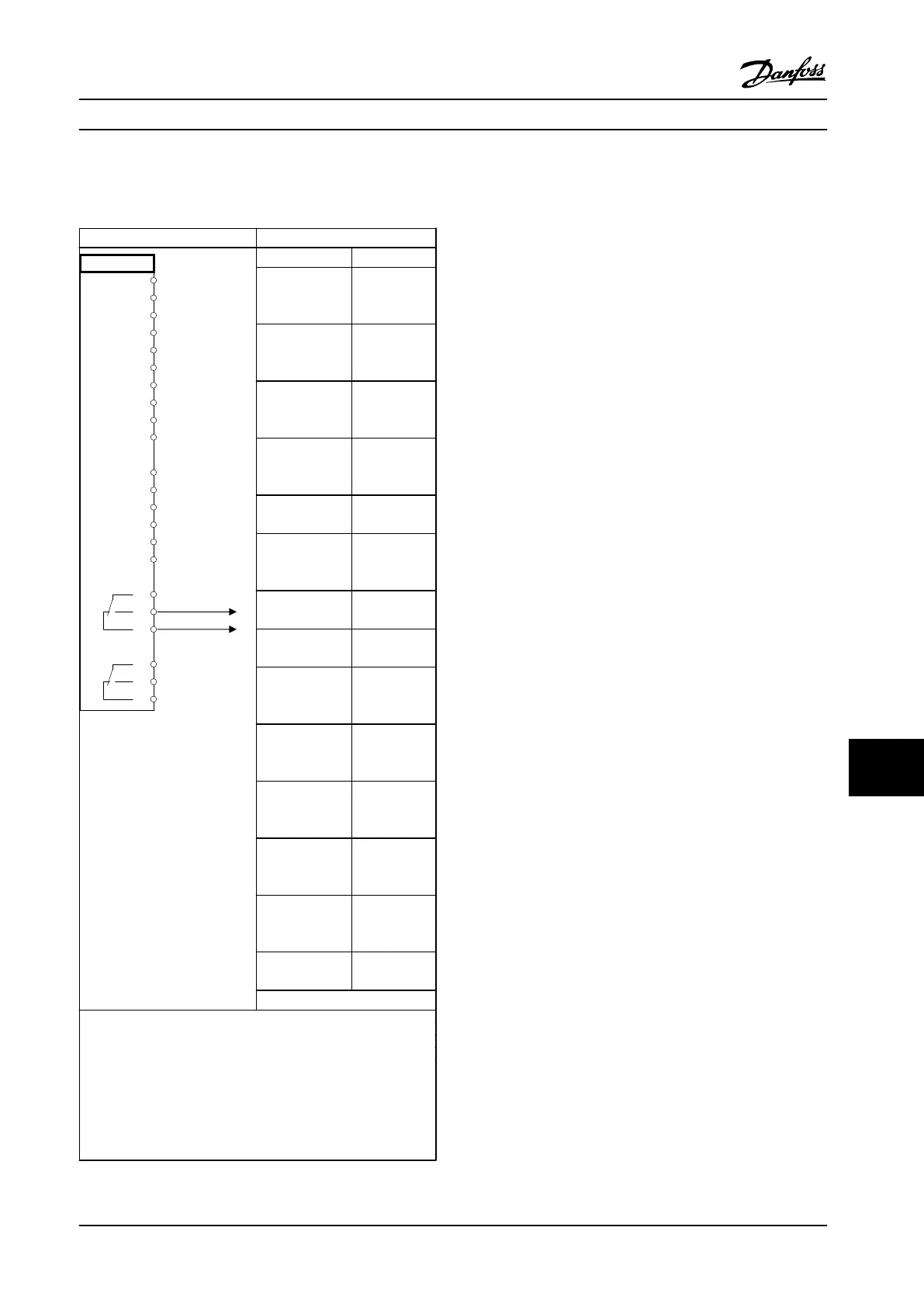

12.9 Wiring Conguration for a Relay Set-up

with Smart Logic Control

Parameters

FC

+24 V

+24 V

D IN

D IN

D IN

COM

D IN

D IN

D IN

D IN

+10 V

A IN

A IN

COM

A OUT

COM

R1R2

12

13

18

19

20

27

29

32

33

37

50

53

54

55

42

39

01

02

03

04

05

06

130BB839.10

Function Setting

Parameter 4-30

Motor Feedback

Loss Function

[1] Warning

Parameter 4-31

Motor Feedback

Speed Error

100 RPM

Parameter 4-32

Motor Feedback

Loss Timeout

5 s

Parameter 7-00 S

peed PID

Feedback Source

[2] MCB 102

Parameter 17-11

Resolution (PPR)

1024*

Parameter 13-00

SL Controller

Mode

[1] On

Parameter 13-01

Start Event

[19] Warning

Parameter 13-02

Stop Event

[44] Reset key

Parameter 13-10

Comparator

Operand

[21] Warning

no.

Parameter 13-11

Comparator

Operator

[1] ≈ (equal)*

Parameter 13-12

Comparator

Value

90

Parameter 13-51

SL Controller

Event

[22]

Comparator 0

Parameter 13-52

SL Controller

Action

[32] Set digital

out A low

Parameter 5-40 F

unction Relay

[80] SL digital

output A

*=Default value

Notes/comments:

If the limit in the feedback monitor is exceeded, warning 90,

Feedback Mon. is issued. The SLC monitors warning 90, Feedback

Mon. and if the warning becomes true, relay 1 is triggered.

External equipment may require service. If the feedback error

goes below the limit again within 5 s, the drive continues and

the warning disappears. Reset relay 1 by pressing [Reset] on the

LCP.

Table 12.13 Wiring Conguration for a Relay Set-up with

Smart Logic Control

12.10 Wiring Conguration for a

Submersible Pump

The system consists of a submersible pump controlled by a

Danfoss VLT

®

AQUA Drive and a pressure transmitter. The

transmitter gives a 4–20 mA feedback signal to the drive,

which keeps a constant pressure by controlling the speed

of the pump. To design a drive for a submersible pump

application, there are a few important issues to consider.

Select the drive according to motor current.

•

The CAN motor is a motor with a stainless steel

can between the rotor and stator that contains a

larger and a more magnetic resistant air-gap than

on a normal motor. This weaker

eld results in

the motors being designed with a higher rated

current than a normal motor with similar rated

power.

•

The pump contains thrust bearings that are

damaged when running below minimum speed,

which is normally 30 Hz.

•

The motor reactance is nonlinear in submersible

pump motors and, therefore, automatic motor

adaption (AMA) may not be possible. Normally,

submersible pumps are operated with long motor

cables that might eliminate the nonlinear motor

reactance and enable the drive to perform AMA.

If AMA fails, the motor data can be set from

parameter group 1-3* Adv. Motor Data (see the

motor datasheet). If AMA has succeeded, the

drive compensates for the voltage drop in the

long motor cables. If the advanced motor data

are set manually, the length of the motor cable

must be considered to optimize system

performance.

•

It is important that the system is operated with a

minimum of wear and tear on the pump and

motor. A Danfoss sine-wave lter can lower the

motor insulation stress and increase lifetime

(check actual motor insulation and the drive

dU/dt

specication). Most manufacturers of

submersible pumps require the use of output

lters.

•

EMC performance can be dicult to achieve

because the special pump cable, which is able to

withstand the wet conditions in the well, is

normally unshielded. A solution could be to use a

shielded cable above the well and attach the

shield to the well pipe, if it is made of steel. A

sine-wave lter also reduces the EMI from

unshielded motor cables.

Application Examples Design Guide

MG22B222 Danfoss A/S © 01/2018 All rights reserved. 203

12 12

Loading...

Loading...