10.6 Motor

Any 3-phase asynchronous standard motor can be used

with a drive.

Terminal Function

96 U/T1

97 V/T2

98 W/T3

99 Ground

Table 10.17 Motor Cable Terminals Providing Clockwise

Rotation (Factory Default)

The direction of rotation can be changed by switching 2

phases in the motor cable, or by changing the setting of

parameter 4-10 Motor Speed Direction.

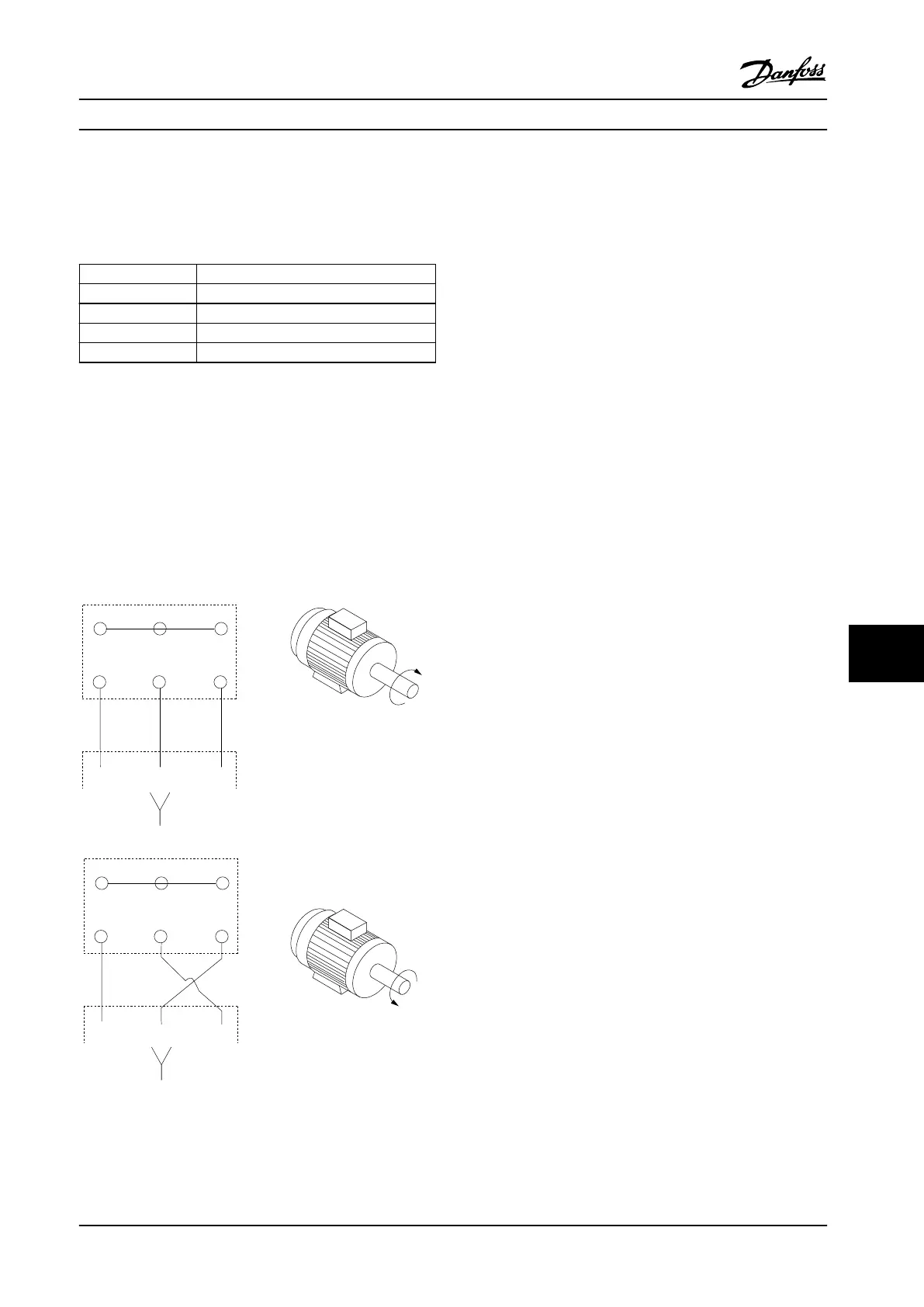

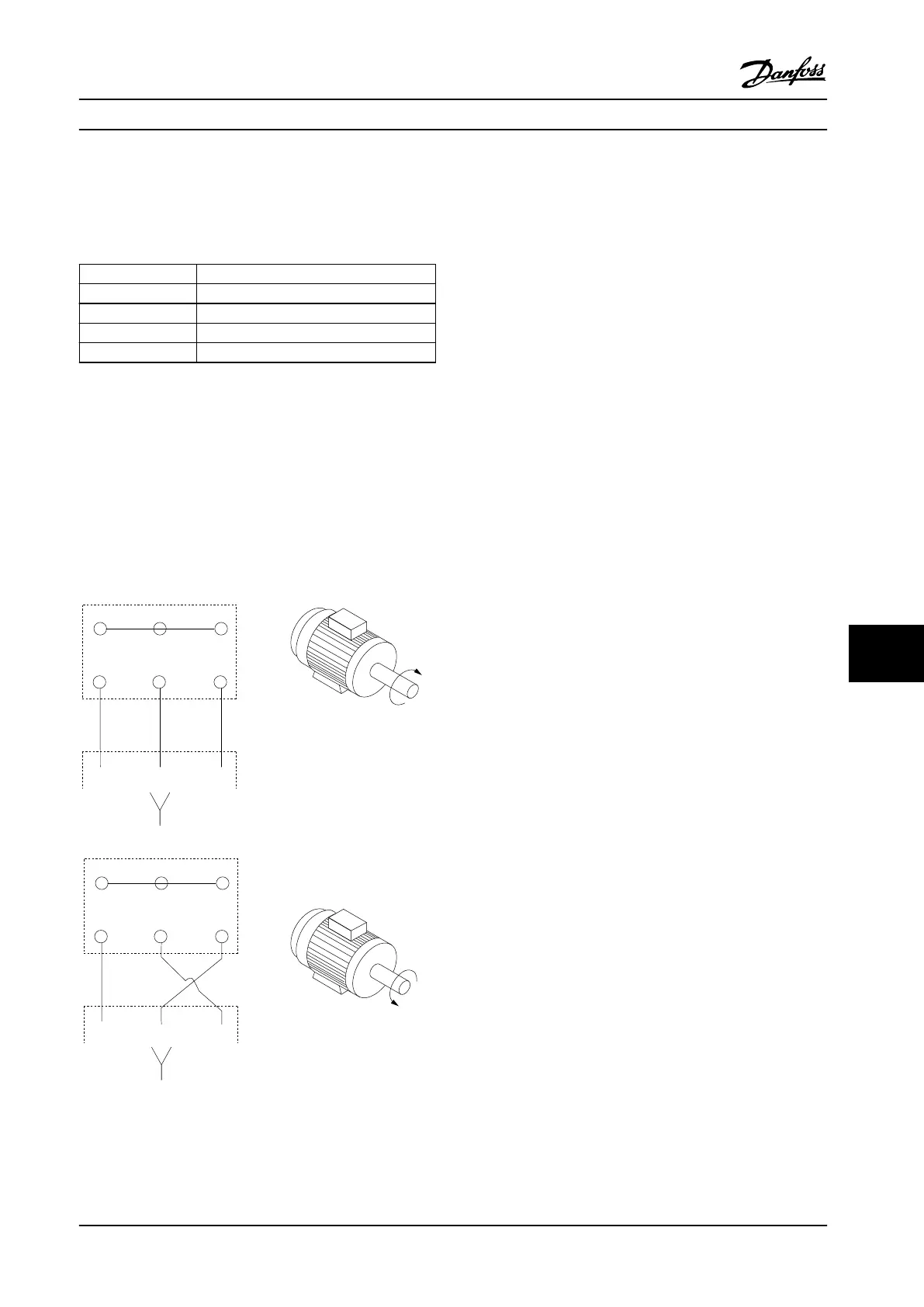

Motor rotation check can be performed using

parameter 1-28 Motor Rotation Check and following the

conguration shown in Figure 10.9.

175HA036.11

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

U

1

V

1

W

1

96 97 98

FC

Motor

U

2

V

2

W

2

Figure 10.9 Changing Motor Rotation

10.6.1 Motor Thermal Protection

The electronic thermal relay in the drive has received UL

approval for single motor overload protection, when

parameter 1-90 Motor Thermal Protection is set for ETR Trip

and parameter 1-24 Motor Current is set to the rated motor

current (see the motor nameplate).

For motor thermal protection, it is also possible to use the

VLT

®

PTC Thermistor Card MCB 112 option. This card

provides ATEX certication to protect motors in explosion

hazardous areas Zone 1/21 and Zone 2/22. When

parameter 1-90 Motor Thermal Protection, set to [20] ATEX

ETR, is combined with the use of MCB 112, it is possible to

control an Ex-e motor in explosion hazardous areas.

Consult the programming guide for details on how to set

up the drive for safe operation of Ex-e motors.

10.6.2 Parallel Connection of Motors

The drive can control several parallel-connected motors.

For dierent congurations of parallel-connected motors,

see Figure 10.10.

When using parallel motor connection, observe the

following points:

•

Run applications with parallel motors in U/F

mode (volts per hertz).

•

VVC

+

mode can be used in some applications.

•

Total current consumption of motors must not

exceed the rated output current I

INV

for the drive.

•

Problems can occur at start and at low RPM if

motor sizes are widely

dierent because the

relatively high ohmic resistance in the stator of a

small motor demands a higher voltage at start

and at low RPM.

•

The electronic thermal relay (ETR) of the drive

cannot be used as motor overload protection.

Provide further motor overload protection by

including thermistors in each motor winding or

individual thermal relays.

•

When motors are connected in parallel,

parameter 1-02 Flux Motor Feedback Source cannot

be used, and parameter 1-01 Motor Control

Principle must be set to [0] U/f.

Electrical Installation Con... Design Guide

MG22B222 Danfoss A/S © 01/2018 All rights reserved. 165

10 10

Loading...

Loading...