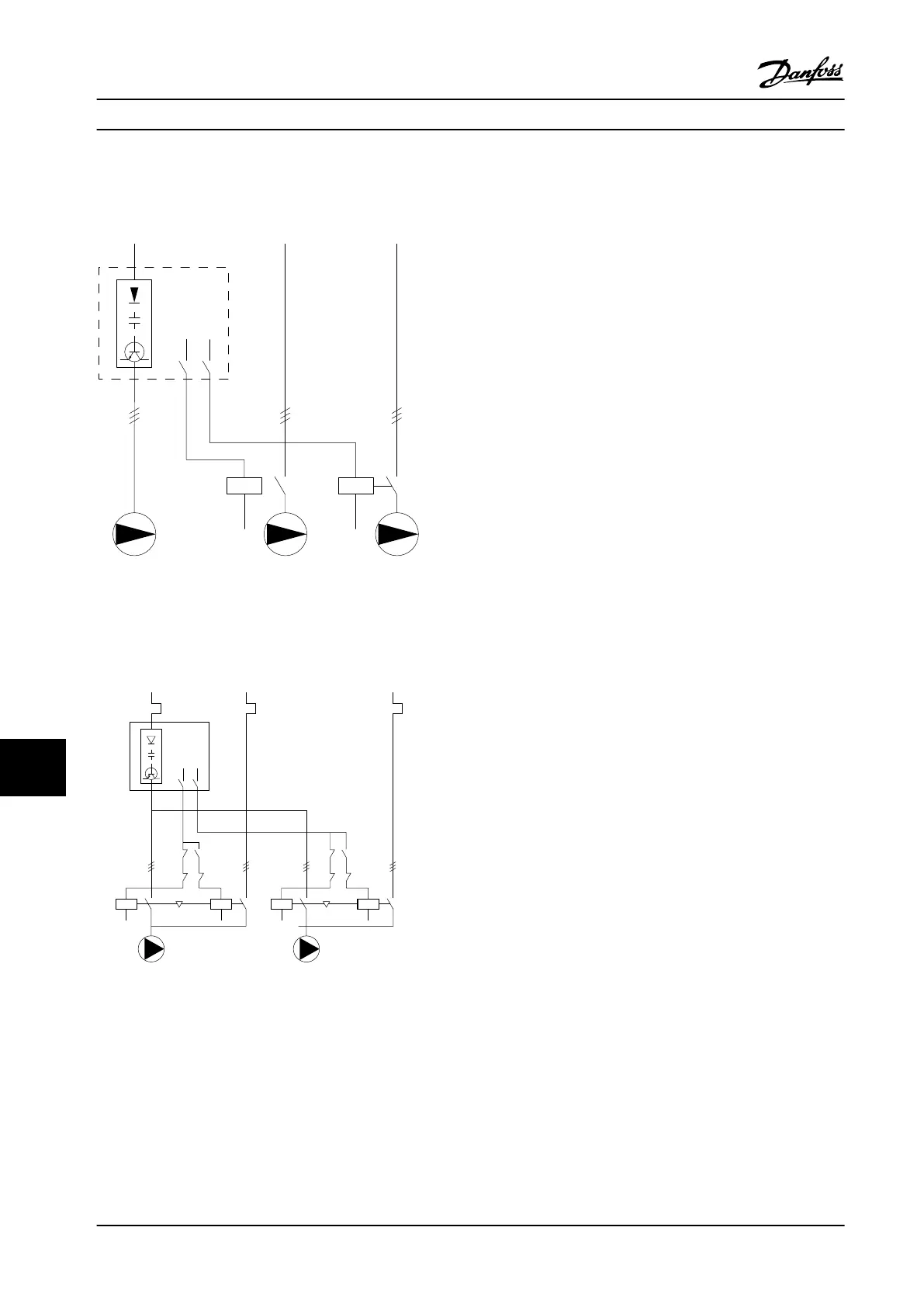

12.12 Wiring Conguration for a Fixed

Variable Speed Pump

L1/L2/L3 L1/L2/L3 L1/L2/L3

Power Section

RELAY 1

RELAY 2

130BA376.10

Figure 12.7 Fixed Variable Speed Pump Wiring Diagram

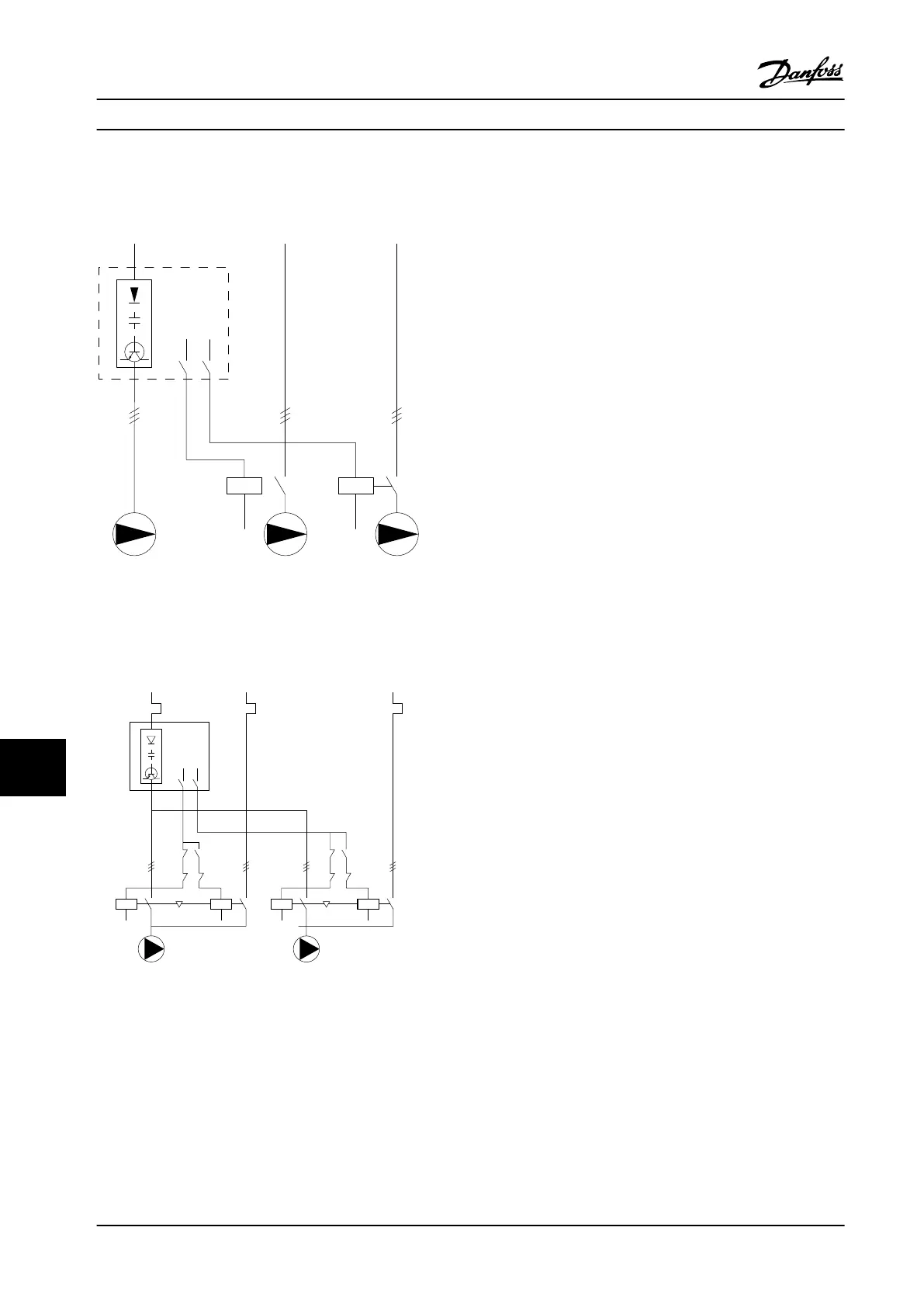

12.13 Wiring Conguration for Lead Pump

Alternation

130BA377.13

L1/L2/L3

FC

L1/L2/L3

L1/L2/L3

k3

k2

k3

k1

K2

K1

K1

K1

K4

K3

K4

K3

R1

R2

Figure 12.8 Lead Pump Alternation Wiring Diagram.

Every pump must be connected to 2 contactors (K1/K2 and

K3/K4) with a mechanical interlock. Thermal relays or other

motor overload protection devices must be applied

according to local regulation and/or individual demands.

•

Relay 1 (R1) and relay 2 (R2) are the built-in relays

in the drive.

•

When all relays are de-energized, the 1

st

built-in

relay that is energized cuts in the contactor

corresponding to the pump controlled by the

relay. For example, relay 1 cuts in contactor K1,

which becomes the lead pump.

•

K1 blocks for K2 via the mechanical interlock,

preventing mains from being connected to the

output of the drive (via K1).

•

Auxiliary break contact on K1 prevents K3 from

cutting in.

•

Relay 2 controls contactor K4 for on/o control of

the xed-speed pump.

•

At alternation, both relays de-energize and now

relay 2 is energized as the 1

st

relay.

For a detailed description of commissioning for mixed

pump and master/slave applications, refer to VLT

®

Cascade

Controller Options MCO 101/102 Operating Instructions.

Application Examples

VLT

®

AQUA Drive FC 202

206 Danfoss A/S © 01/2018 All rights reserved. MG22B222

1212

Loading...

Loading...