1-90 Motor Thermal Protection

Option: Function:

[20] ATEX ETR

[21] Advanced ETR

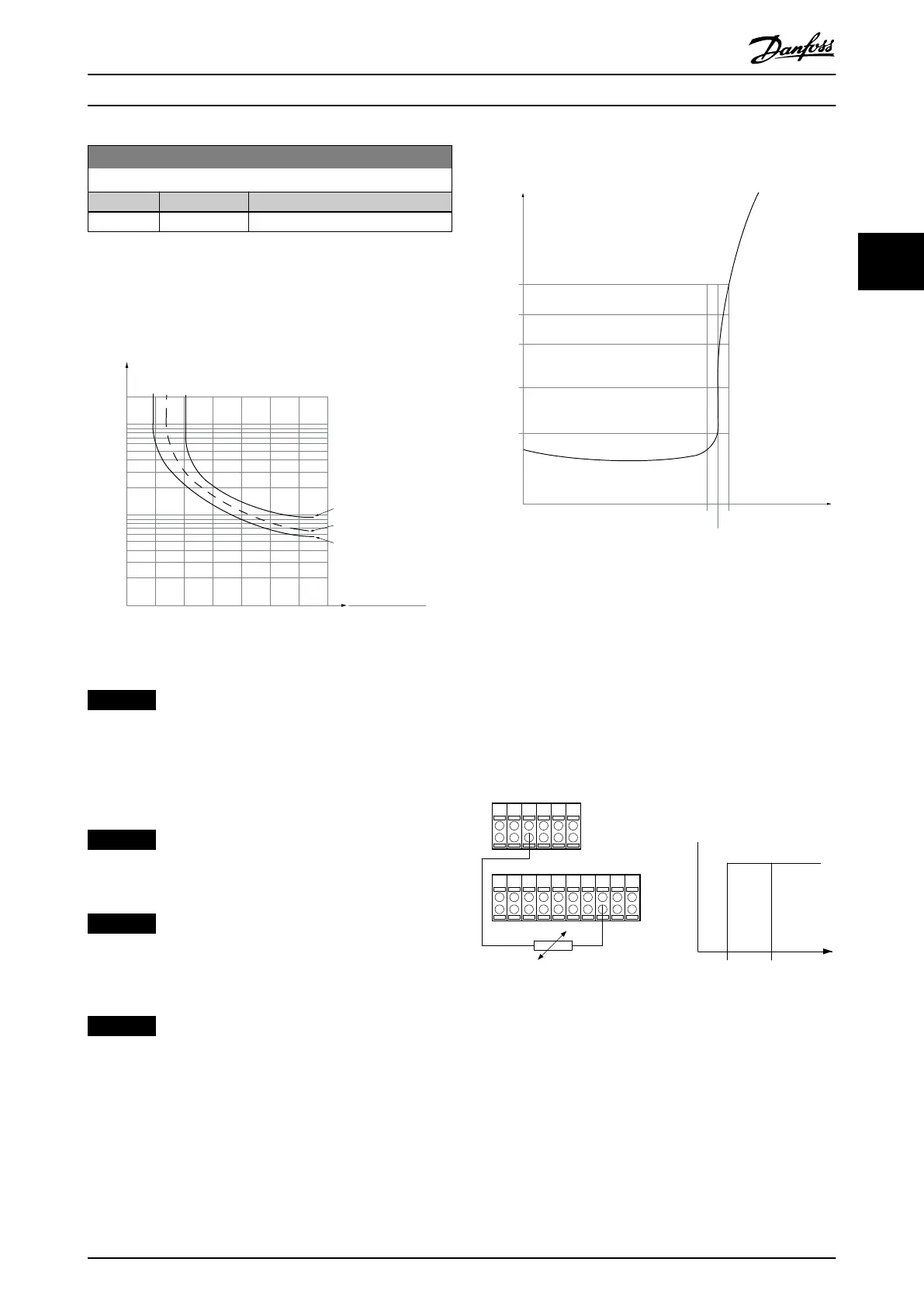

ETR functions 1-4 calculate the load when the set-up

where they were selected is active. For example, ETR-3

starts calculating when set-up 3 is selected. For the North

American market: The ETR functions provide class 20

motor overload protection in accordance with NEC.

1.21.0 1.4

30

10

20

100

60

40

50

1.81.6 2.0

2000

500

200

400

300

1000

600

t [s]

175ZA052.12

f

OUT

= 2 x f

M,N

f

OUT

= 0.2 x f

M,N

f

OUT

= 1 x f

M,N

(par. 1-23)

I

MN

(par. 1-24)

I

M

Illustration 3.10 Thermal Motor Protection

NOTICE

If the temperature of the motor is monitored through a

thermistor or a KTY Sensor, the PELV is not complied

with in case of short circuits between motor windings

and the sensor. To comply with PELV, isolate the sensor

appropriately.

NOTICE

Danfoss recommends using 24 V DC as thermistor supply

voltage.

NOTICE

The ETR timer function does not work when

parameter 1-10 Motor Construction=[1] PM, non-salient

SPM.

NOTICE

For correct operation of the ETR function, the setting in

parameter 1-03 Torque Characteristics must t the

application (see description of parameter 1-03 Torque

Characteristics).

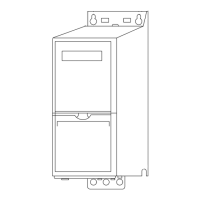

3.3.13.1 PTC Thermistor Connection

1330

550

250

-20 °C

175HA183.11

4000

3000

R

(Ω)

nominal

nominal -5 °C nominal +5 °C

[°C]

Illustration 3.11 PTC Prole

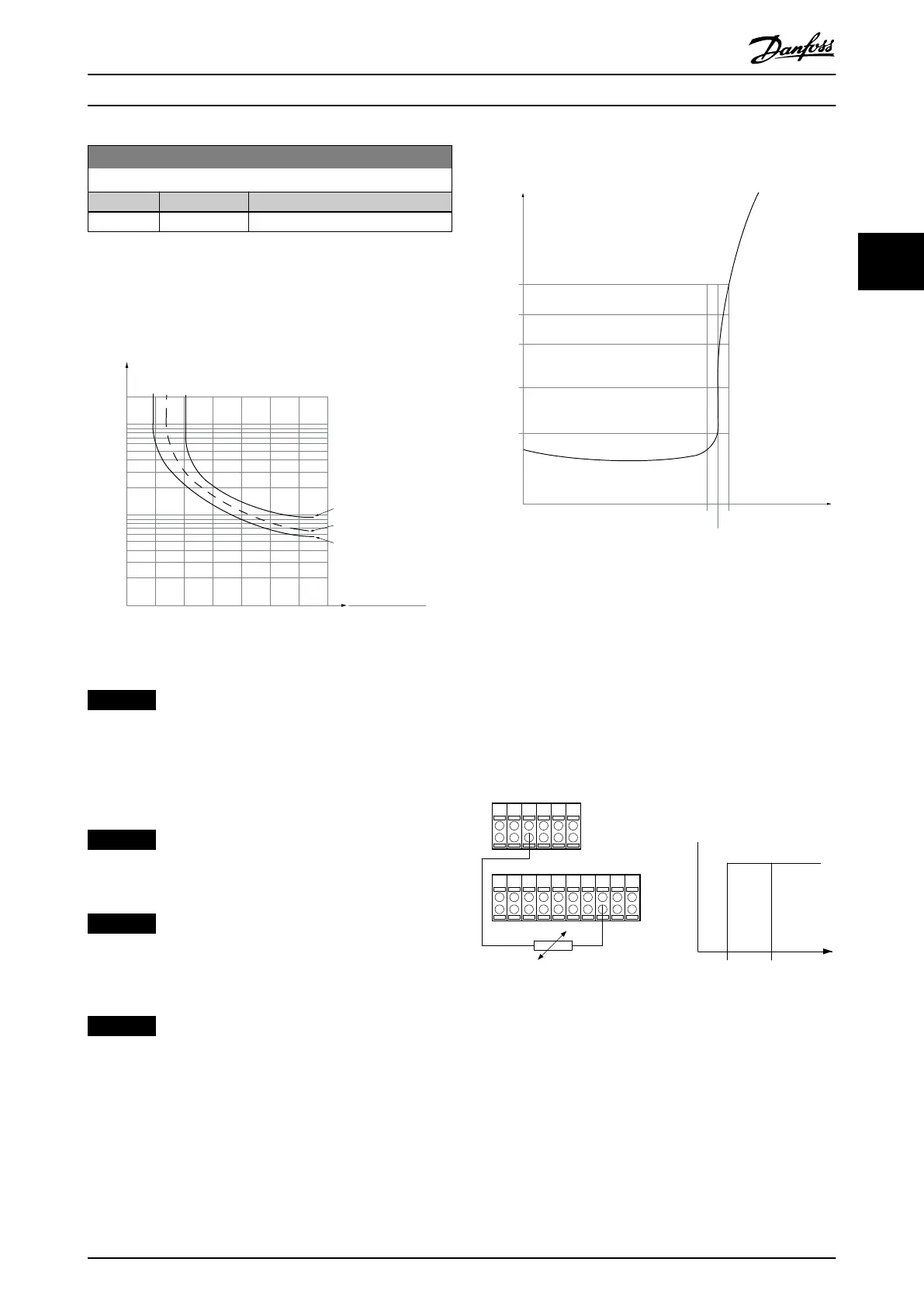

Example using a digital input and 10 V as supply

The frequency converter trips when the motor temperature

is too high.

Parameter set-up:

•

Set parameter 1-90 Motor Thermal Protection to [2]

Thermistor Trip.

•

Set parameter 1-93 Thermistor Source to [6] Digital

Input.

PTC / Thermistor

R

OFF

ON

<800 Ω

+10V

130BA152.10

>2.7 kΩ

12 13 18 37322719 29 33 20

5550

39 42 53 54

Illustration 3.12 PTC Thermistor Connection - Digital Input

Example using an analog input and 10 V as supply

The frequency converter trips when the motor temperature

is too high.

Parameter set-up:

•

Set parameter 1-90 Motor Thermal Protection to [2]

Thermistor Trip.

•

Set parameter 1-93 Thermistor Source to [2] Analog

Input 54.

Parameter Descriptions Programming Guide

M0010001 Danfoss A/S © 10/2019 All rights reserved. 67

3 3

Loading...

Loading...