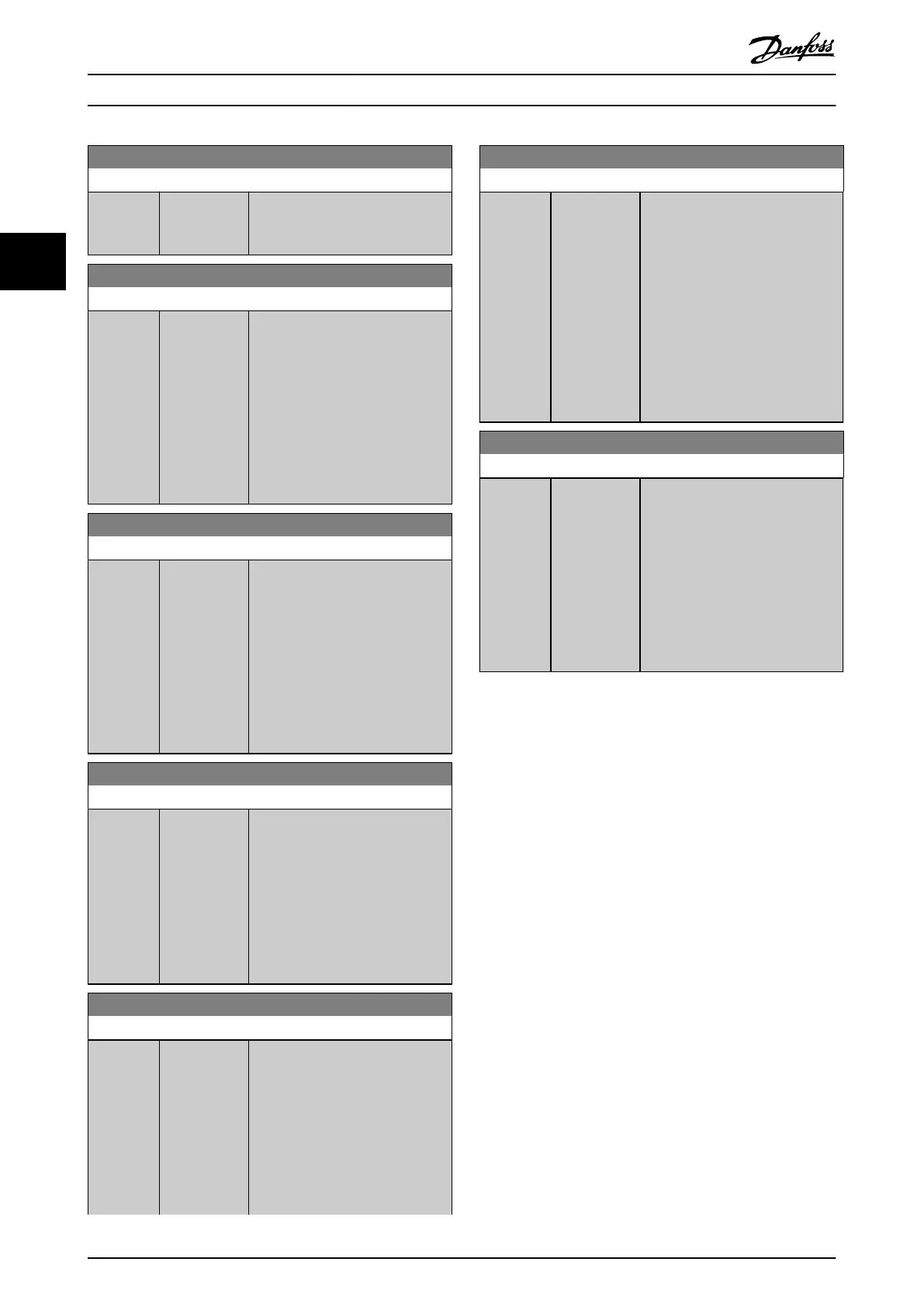

22-41 Minimum Sleep Time

Range: Function:

10 s* [0 - 600 s] Set the minimum time for staying

in sleep mode. This setting

overrides any wake-up conditions.

22-42 Wake-up Speed [RPM]

Range: Function:

Size

related*

[ par. 4-11 -

par. 4-13 RPM]

To be used if parameter 0-02 Motor

Speed Unit has been set for [0] RPM

(parameter not visible if [1] Hz is

selected). Only to be used if

parameter 1-00 Conguration Mode

is set for [0] Open loop and an

external controller applies speed

reference.

Set the reference speed at which

the sleep mode should be canceled.

22-43 Wake-up Speed [Hz]

Range: Function:

Size

related*

[ par. 4-12 -

par. 4-14 Hz]

To be used if parameter 0-02 Motor

Speed Unit has been set for [1] Hz

(parameter not visible if [0] RPM is

selected). Only to be used if

parameter 1-00 Conguration Mode

is set for [0] Open Loop and speed

reference is applied by an external

controller controlling the pressure.

Set the reference speed at which

the sleep mode should be canceled.

22-44 Wake-up Ref./FB Dierence

Range: Function:

10 %* [0 - 100 %] Only to be used if

parameter 1-00 Conguration Mode

is set for [3] Process Closed Loop and

the integrated PI controller is used

for controlling the pressure.

Set the pressure drop allowed in

percentage of setpoint for the

pressure (P

set

) before canceling the

sleep mode.

22-45 Setpoint Boost

Range: Function:

0 %* [-100 -

100 %]

Only to be used if

parameter 1-00 Conguration Mode

is set to [3] Closed Loop and the

integrated PI controller is used. In

systems with, for example, constant

pressure control, it is advantageous

to increase the system pressure

before the motor is stopped. This

extends the time in which the

22-45 Setpoint Boost

Range: Function:

motor is stopped and helps to

avoid frequent start/stop.

Set the overpressure/overtem-

perature in percentage of the

setpoint for the pressure (P

set

)/

temperature before entering sleep

mode.

If set to 5%, the boost pressure is

P

set

x1.05. The negative values can

be used, for example, in cooling

tower control where a negative

change is needed.

22-46 Maximum Boost Time

Range: Function:

60 s* [0 - 600 s] Only to be used if

parameter 1-00 Conguration Mode

is set to [3] Closed Loop and the

integrated PI controller is used for

controlling the pressure.

Set the maximum time for which

boost mode is allowed. If the set

time is exceeded, sleep mode is

entered, not waiting for the set

boost pressure to be reached.

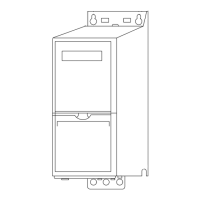

3.20.4 22-5* End of Curve

The end-of-curve conditions occur when a pump is

yielding a too large volume to ensure the set pressure. This

situation can occur if there is a leakage in the distribution

pipe system after the pump causing the pump to operate

at the end of the pump characteristic, valid for the

maximum speed set in parameter 4-13 Motor Speed High

Limit [RPM] or parameter 4-14 Motor Speed High Limit [Hz].

If the feedback is 2.5% of the programmed value in

parameter 20-14 Maximum Reference/Feedb. (or numerical

value of parameter 20-13 Minimum Reference/Feedb.

whichever is highest) below the setpoint for the required

pressure for a set time (parameter 22-51 End of Curve

Delay), and the pump runs with maximum speed set in

parameter 4-13 Motor Speed High Limit [RPM] or

parameter 4-14 Motor Speed High Limit [Hz], the function

selected in parameter 22-50 End of Curve Function takes

place.

It is possible to get a signal on 1 of the digital outputs by

selecting [192] End of Curve in parameter group 5-3* Digital

Outputs and/or parameter group 5-4* Relays. The signal is

present, when an end-of-curve condition occurs and the

selection in parameter 22-50 End of Curve Function is

dierent from [0] O. The end-of-curve function can only

be used when operating with the built-in PID controller

([3] Closed loop in parameter 1-00 Conguration Mode).

Parameter Descriptions

VLT

®

HVAC Drive FC 102

206 Danfoss A/S © 10/2019 All rights reserved. M0010001

33

Loading...

Loading...