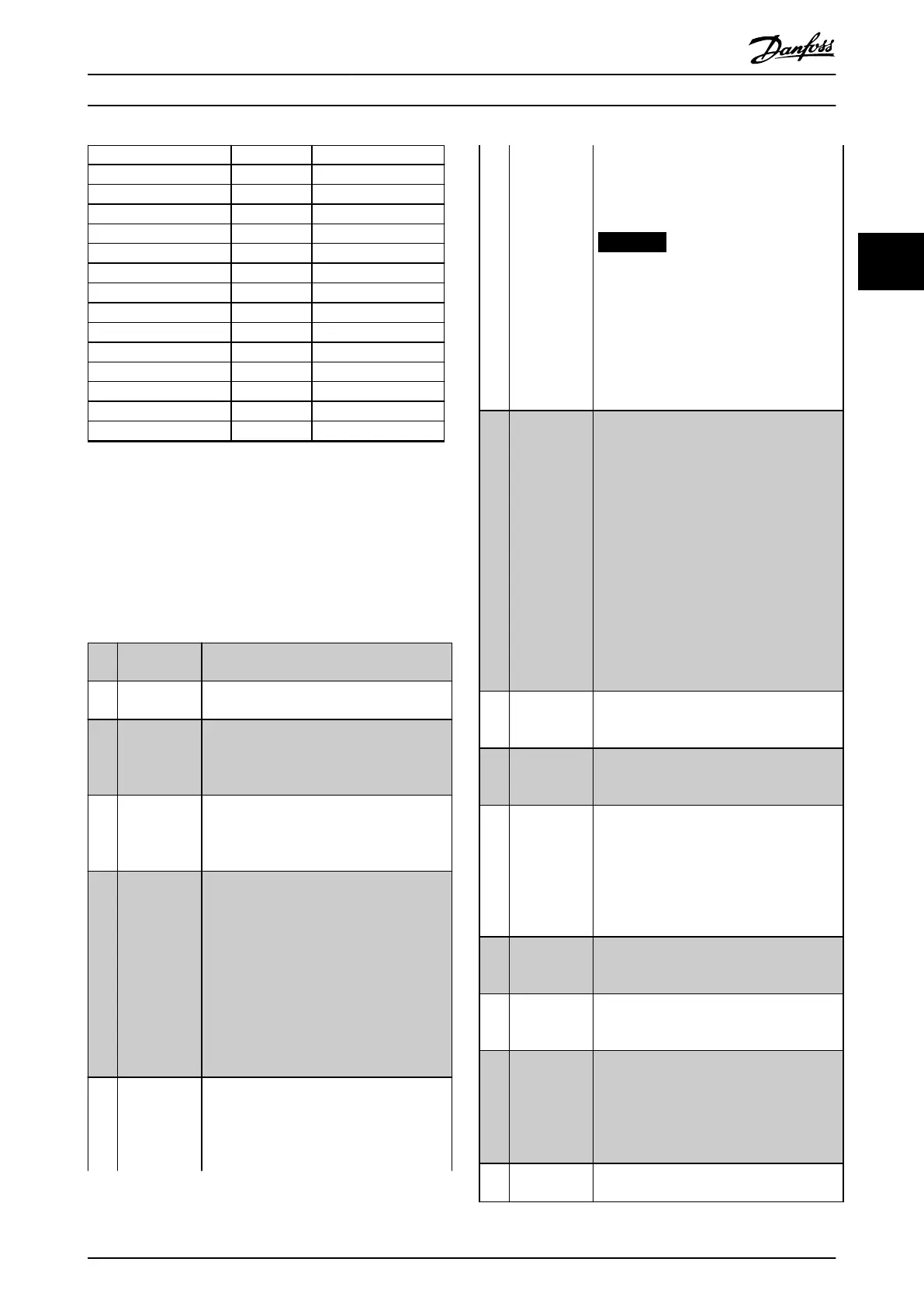

Digital input function Select Terminal

Counter A (up) [60] 29, 33

Counter A (down) [61] 29, 33

Reset counter A [62] All

Counter B (up) [63] 29, 33

Counter B (down) [64] 29, 33

Reset counter B [65] All

Sleep mode [66] All

Reset maintenance word [78] All

PTC card 1 [80] All

Lead pump start [120] All

Lead pump alternation [121] All

Pump 1 interlock [130] All

Pump 2 interlock [131] All

Pump 3 interlock [132] All

All=Terminals 18, 19, 27, 29, 32, 33, X30/2, X30/3, X30/4.

X30/ are the terminals on VLT

®

General Purpose I/O MCB

101.

Functions dedicated to only 1 digital input are stated in

the associated parameter.

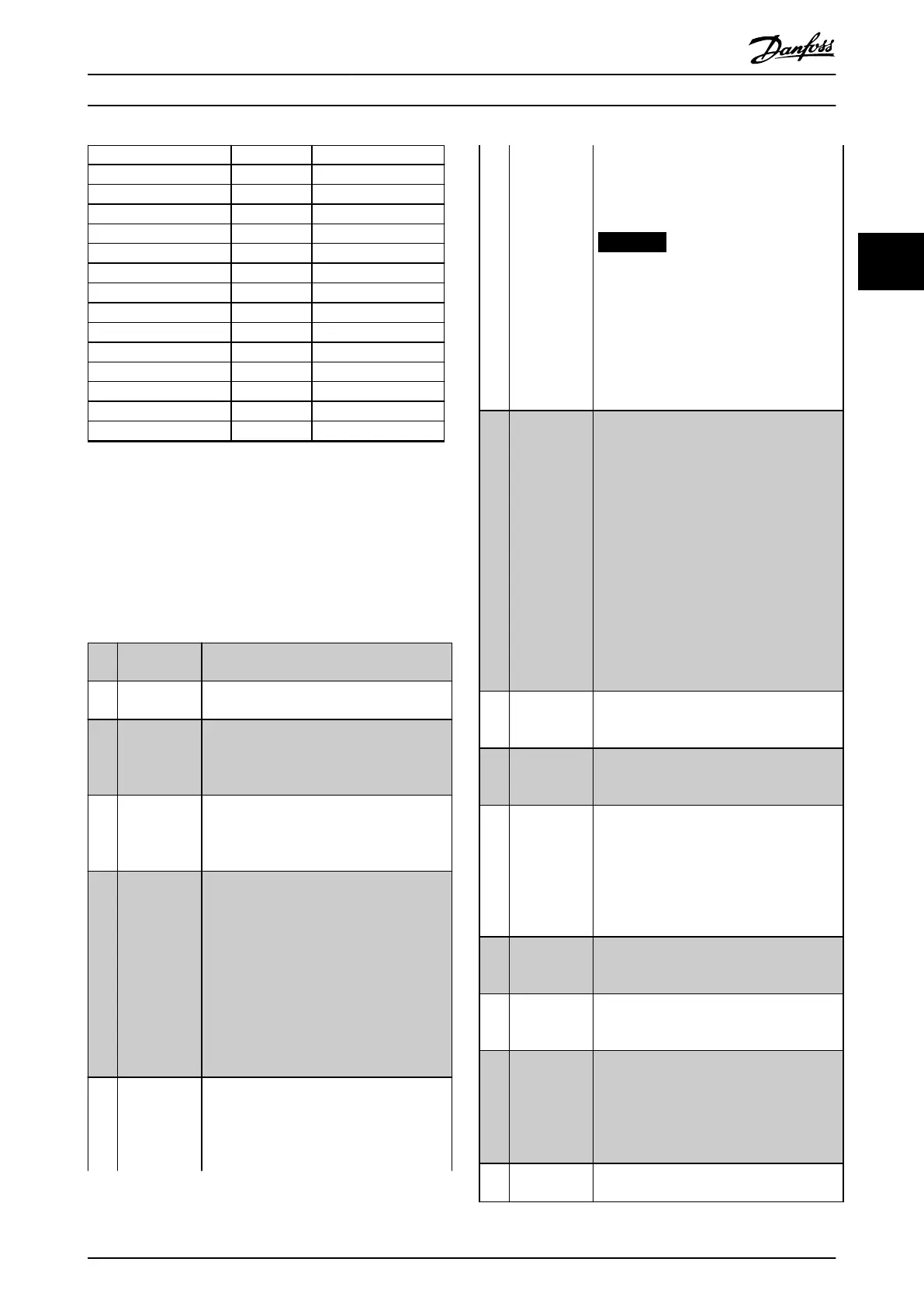

All digital inputs can be programmed to these functions

[0] No operation No reaction to signals transmitted to

terminal.

[1] Reset Resets frequency converter after a trip/

alarm. Not all alarms can be reset.

[2] Coast inverse Leaves motor in free mode. Logic

0⇒coasting stop.

(Default Digital input 27): Coasting stop,

inverted input (NC).

[3] Coast and

reset inverse

Reset and coasting stop, inverted input (NC).

Leaves motor in free mode and resets the

frequency converter. Logic 0⇒coasting stop

and reset.

[5] DC-brake

inverse

Inverted input for DC braking (NC).

Stops motor by energizing it with a DC

current for a certain time period. See

parameter 2-01 DC Brake Current to

parameter 2-03 DC Brake Cut In Speed [RPM].

The function is only active when the value

in parameter 2-02 DC Braking Time is

dierent from 0. Logic 0⇒DC braking.

This selection is not possible when

parameter 1-10 Motor Construction is set to

[1] PM non-salient SPM.

[6] Stop inverse Stop inverted function. Generates a stop

function when the selected terminal goes

from logical level 1 to 0. The stop is

performed according to the selected ramp

time

•

Parameter 3-42 Ramp 1 Ramp Down

Time

•

Parameter 3-52 Ramp 2 Ramp Down

Time

NOTICE

When the frequency converter is at

the torque limit and has received a

stop command, it may not stop by

itself. To ensure that the frequency

converter stops, congure a digital

output to [27] Torque limit & stop and

connect this digital output to a digital

input that is congured as coast.

[7] External

Interlock

Same function as coasting inverse and stop

inverse, but this option generates the alarm

message External fault on the display when

the terminal programmed for coast inverse

has signal 0. The alarm message is also

active via digital outputs and relay outputs,

if programmed for external interlock. When

the external interlock is removed, the alarm

can be reset using a digital input or the

[RESET] key. A delay can be programmed in

parameter 22-00 External Interlock Delay.

After applying a signal to the input, the

reaction described above is delayed with the

time set in parameter 22-00 External Interlock

Delay.

[8] Start Select start for a start/stop command. Logic

1=start, logic 0=stop.

(Default: Digital input 18).

[9] Latched start The motor starts, if a pulse is applied for

minimum. 2 ms. The motor stops when stop

inverse is activated.

[10] Reversing Changes direction of motor shaft rotation.

Select Logic 1 to reverse. The reversing

signal only changes the direction of rotation.

It does not activate the start function. Select

both directions in parameter 4-10 Motor

Speed Direction.

(Default: Digital input 19).

[11] Start

reversing

Used for start/stop and for reversing on the

same wire. Signals on start are not allowed

at the same time.

[14] Jog Used for activating jog speed. See

parameter 3-11 Jog Speed [Hz].

(Default: Digital input 29)

[15] Preset

reference on

Used for shifting between external reference

and preset reference. It is assumed that

External/preset [1] has been selected in

parameter 3-04 Reference Function. Logic

0=external reference active; logic 1=1 of the

8 preset references is active.

[16] Preset ref bit

0

Enables a choice between 1 of the 8 preset

references according to Table 3.13.

Parameter Descriptions Programming Guide

M0010001 Danfoss A/S © 10/2019 All rights reserved. 87

3 3

Loading...

Loading...