•

•

•

•

•

•

•

•

•

•

-

-

-

-

-

-

4.3 Grounding

W A R N I N G

ELECTRICAL SHOCK HAZARD - LEAKAGE CURRENT HAZARD >3.5 MA

Leakage currents exceed 3.5 mA. Failure to connect the drive properly to protective earth (PE) can result in death or serious in-

jury.

Ensure reinforced protective earthing conductor according to IEC 60364-5-54 cl. 543.7 or according to local safety regula-

tions for high touch current equipment. The reinforced protective earthing of the drive can be done with:

a PE conductor with a cross-section of at least 10 mm

2

(8 AWG) Cu or 16 mm

2

(6 AWG) Al.

an extra PE conductor of the same cross-sectional area as the original PE conductor as specified by IEC 60364-5-54 with a

minimum cross-sectional area of 2.5 mm

2

(14 AWG) (mechanical protected) or 4 mm

2

(12 AWG) (not mechanical protected).

a PE conductor completely enclosed with an enclosure or otherwise protected throughout its length against mechanical

damage.

a PE conductor part of a multi-conductor power cable with a minimum PE conductor cross-section of 2.5 mm

2

(14 AWG)

(permanently connected or pluggable by an industrial connector. The multi-conductor power cable shall be installed with an

appropriate strain relief).

NOTE: In IEC/EN 60364-5-54 cl. 543.7 and some application standards (for example IEC/EN 60204-1), the limit for requiring

reinforced protective earthing conductor is 10 mA leakage current.

For electrical safety

Ground the drive in accordance with applicable standards and directives.

Use a dedicated ground wire for input power, motor power, and control wiring.

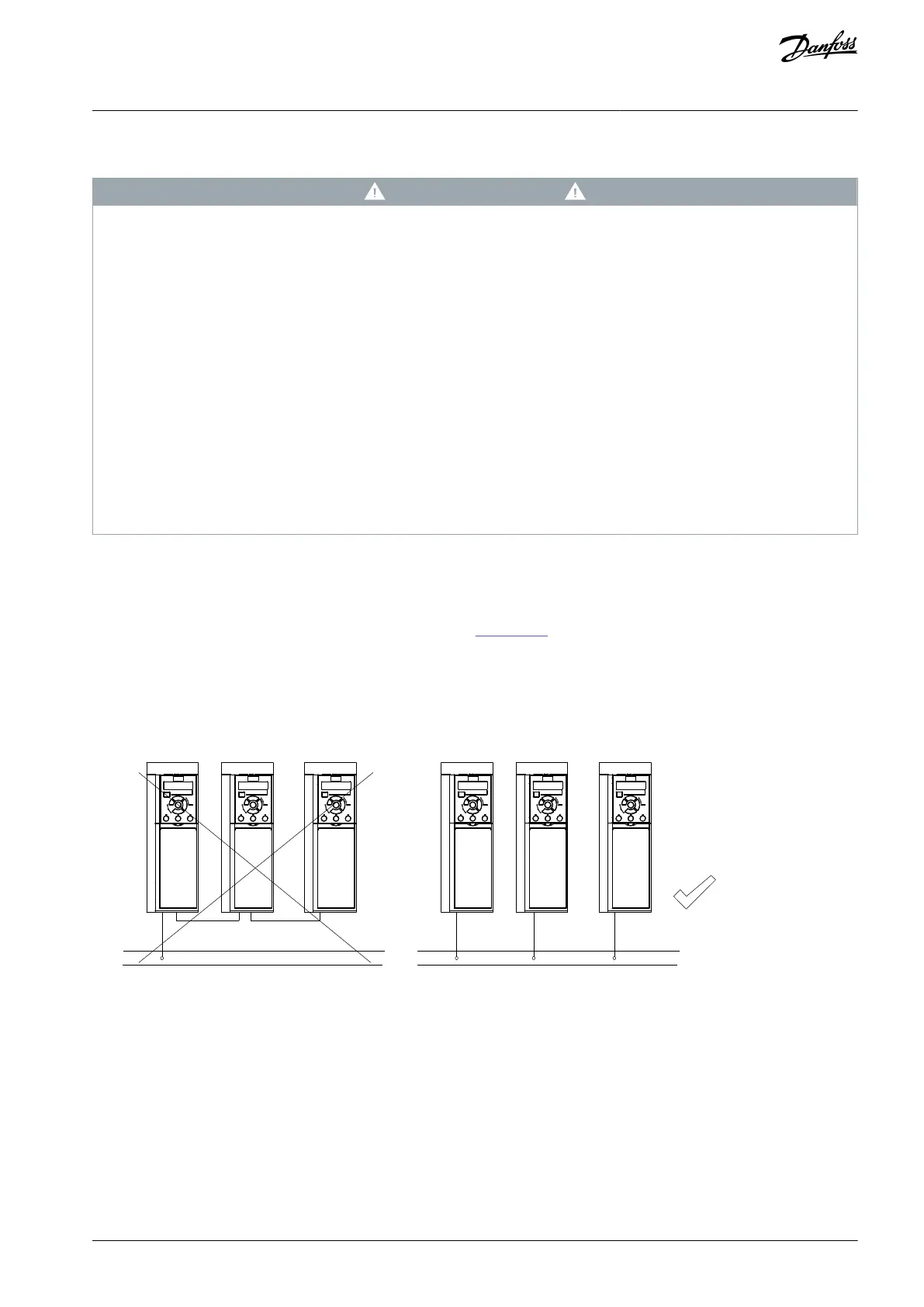

Do not ground 1 drive to another in a daisy chain fashion (see

Illustration 7).

Keep the ground wire connections as short as possible.

Follow motor manufacturer wiring requirements.

Minimum cable cross-section for the ground wires: 10 mm

2

(7 AWG).

Separately terminate individual ground wires, both complying with the dimension requirements.

e30bc500.12

FC 1

FC 1

FC 2

FC 2

FC 3

FC 3

PE

PE

A

B

Illustration 7: Grounding Principle

For EMC-compliant installation

Establish electrical contact between the cable shield and the drive enclosure by using metal cable glands or by using the clamps

provided on the equipment.

Use high-strand wire to reduce burst transient.

Do not use pigtails.

AQ267037536117en-000101 / 130R0083 | 21Danfoss A/S © 2023.09

Electrical Installation

VLT HVAC Drive FC 102

Operating Guide

Loading...

Loading...