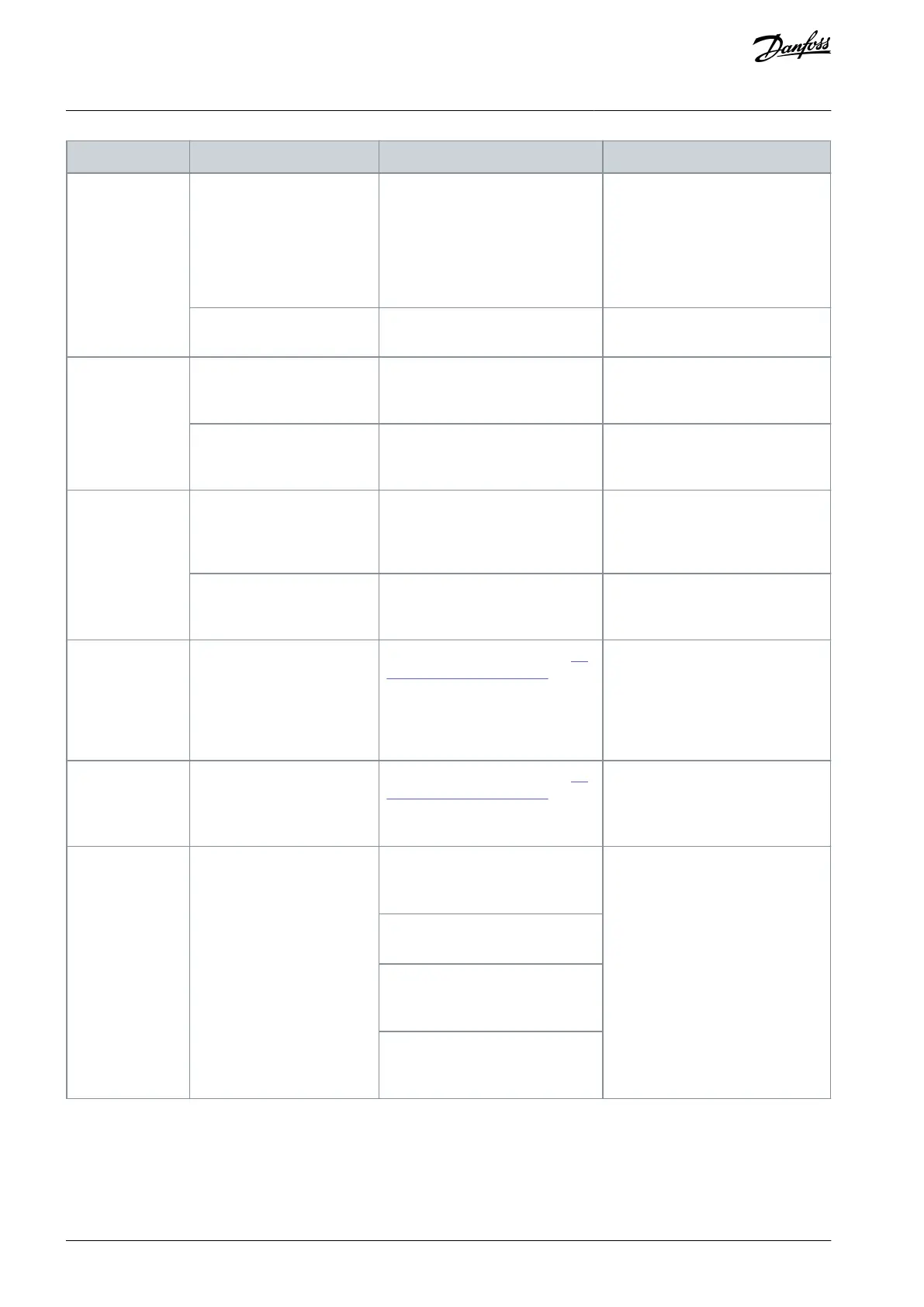

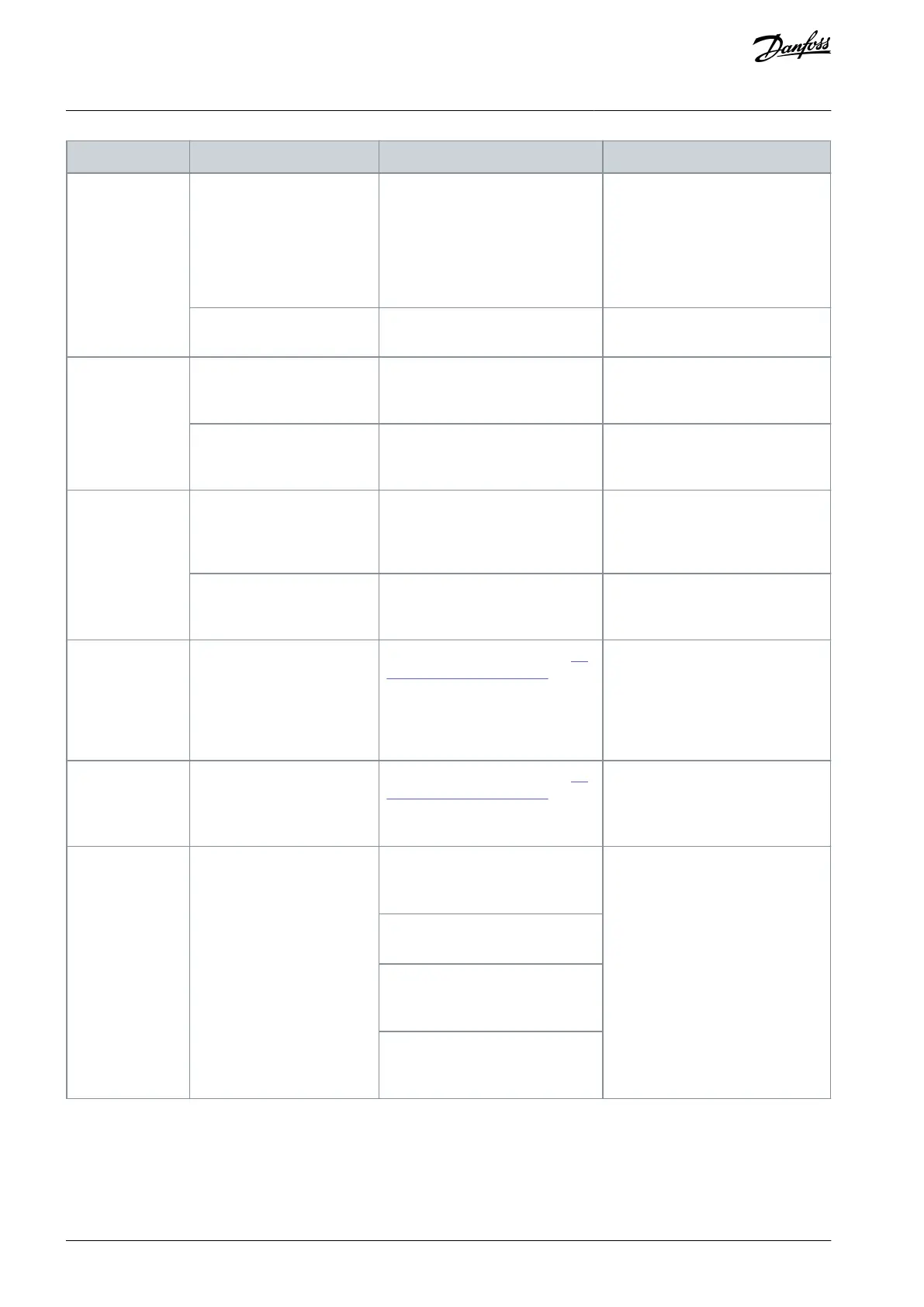

Motor is overloaded for the applica-

tion.

Perform start-up test and verify that

motor current is within the specifi-

cations. If motor current exceeds

nameplate full load current, the mo-

tor may run only with reduced load.

Review the specifications for the ap-

plication.

Perform a pre-start-up check to

check for loose connections.

Tighten loose connections.

Mains current im-

balance >3%.

Problem with mains power

(see alarm 4, Mains phase loss

description.

Rotate input power leads into the

drive by 1 position: A to B, B to C, C

to A.

If imbalanced leg follows the wire, it

is a power problem. Check mains

power supply.

Rotate input power leads in to drive

by 1 position: A to B, B to C, C to A.

If imbalanced leg stays on the same

input terminal, it is a problem with

the unit. Contact the supplier.

Motor current im-

balance >3%

Problem with motor or motor

wiring.

Rotate output motor leads by 1 po-

sition: U to V, V to W, W to U.

If imbalanced leg follows the wire,

the problem is in the motor or mo-

tor wiring. Check the motor and mo-

tor wiring.

Rotate output motor leads by 1 po-

sition: U to V, V to W, W to U.

If imbalanced leg stays on the same

output terminal, it is a problem with

the unit. Contact the supplier.

Drive acceleration

problems.

Motor data is entered incor-

rectly.

If warnings or alarms occur, see 7.6

List of Warnings and Alarms. Check

that motor data is entered correct-

ly.

Increase the ramp-up time in param-

eter 3-41 Ramp 1 Ramp Up Time. In-

crease current limit in parameter

4-18 Current Limi. Increase torque

limit in parameter4-16 Torque Limit

Motor Mode.

Drive deceleration

problems.

Motor data is entered incor-

rectly.

If warnings or alarms occur, see 7.6

List of Warnings and Alarms. Check

that motor data is entered correct-

ly.

Increase ramp-down time in param-

eter 3-42 Ramp 1 Ramp Down Time.

Enable overvoltage control in pa-

rameter 2-17 Over-voltage Control.

Acoustic noise or

vibration (for ex-

ample, a fan blade

is making noise or

vibrations at cer-

tain frequencies).

Resonance, for example in

the motor/fan system.

Bypass critical frequencies by using

parameters in parameter group 4-6*

Speed Bypass.

Check if noise and/or vibration have

been reduced to an acceptable limit.

Turn off overmodulation in parame-

ter 14-03 Overmodulation.

Change switching pattern and fre-

quency parameter group 14-0* In-

verter Switching.

Increase resonance dampening in

parameter 1-64 Resonance Dampen-

ing.

AQ267037536117en-000101 / 130R008384 | Danfoss A/S © 2023.09

Diagnostics and Troubleshooting

VLT HVAC Drive FC 102

Operating Guide

Loading...

Loading...