OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

46 / KEYBOARD PROGRAMMING

Figure 31

Configuring the Granular Channel

Check each following item for a desired setting.

– SPR CON (Spreader Constant) – Represents the number of pulses

generated by the application rate sensor per pound of material (P/

LB) discharged from the spreader.

The spreader constant differs for each granular material, spreader

vehicle, and gate height setting. If the spreader constant is known,

keyboard enter the value so that running the GRANULAR

CALIBRATION routine for this material is unnecessary. If the

spreader constant is unknown, leave the displayed value. The

correct value is automatically corrected later, during GRANULAR

CALIBRATION.

– CAL GT HGT (Calibration Gate Height) - Displayed only if optional

Gate Height Sensor is Enabled. If Enabled, the Calibration Gate

Height valve displayed is the setting of the gate height in inches

when the spreader was calibrated. Refer to page 77 for the

Spreader Calibration procedure.

Changing the original calibrated gate setting by adjusting the

conveyor speed provides a more accurate granular material

application. Increased Gate Height decreases conveyor speed;

Decreased Gate Height increases conveyor speed.

– DRV FREQ (Drive Frequency) – Represents the valve

manufacturer’s suggested drive frequency, as shown on the valve

specification sheet.

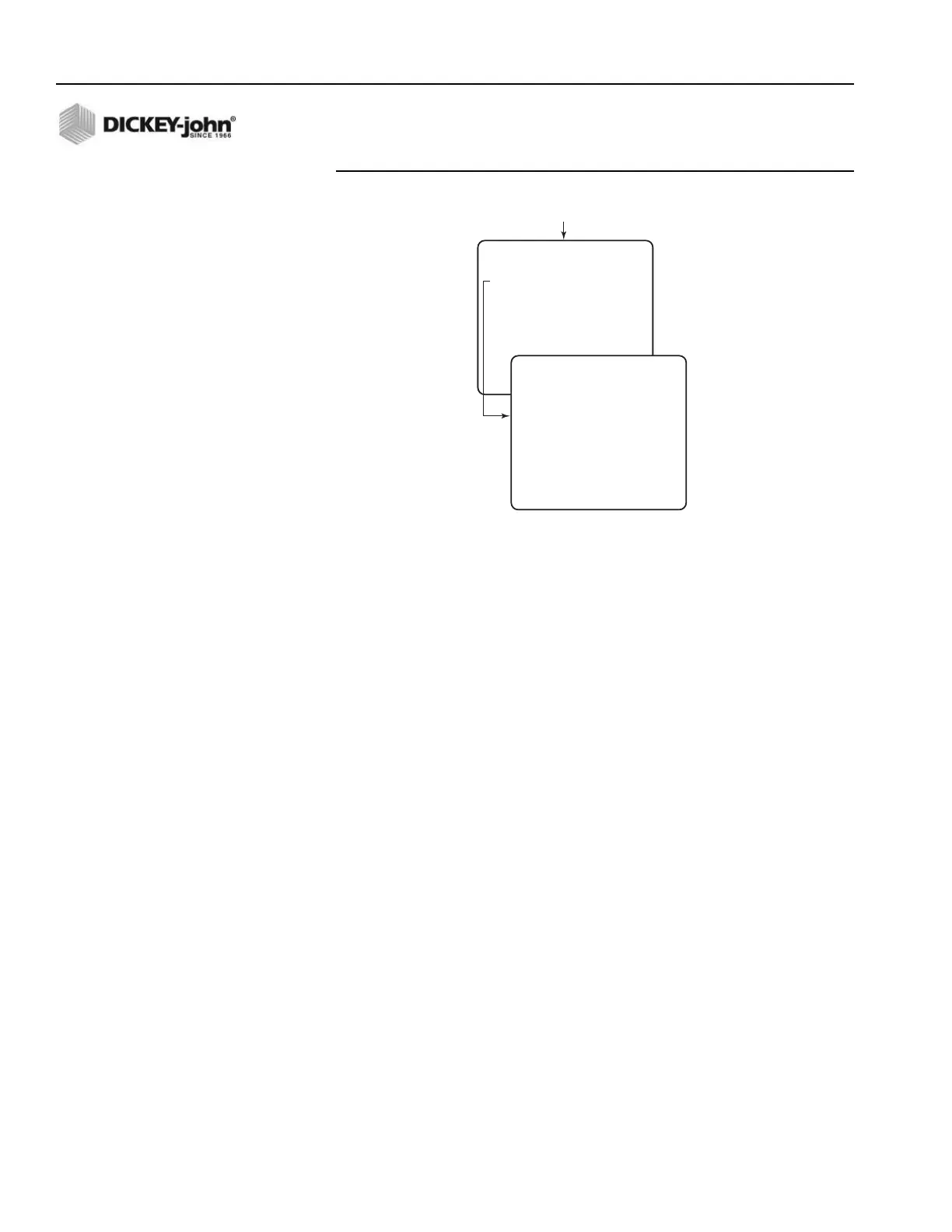

CONFIGURATION

SELECT A MENU ITEM

1 SALT ENABLED

2 SAND DISABLED

3 MIX A DISABLED

4 MIX B DISABLED

Press Function Key F3

(GRANULAR CONFIG)

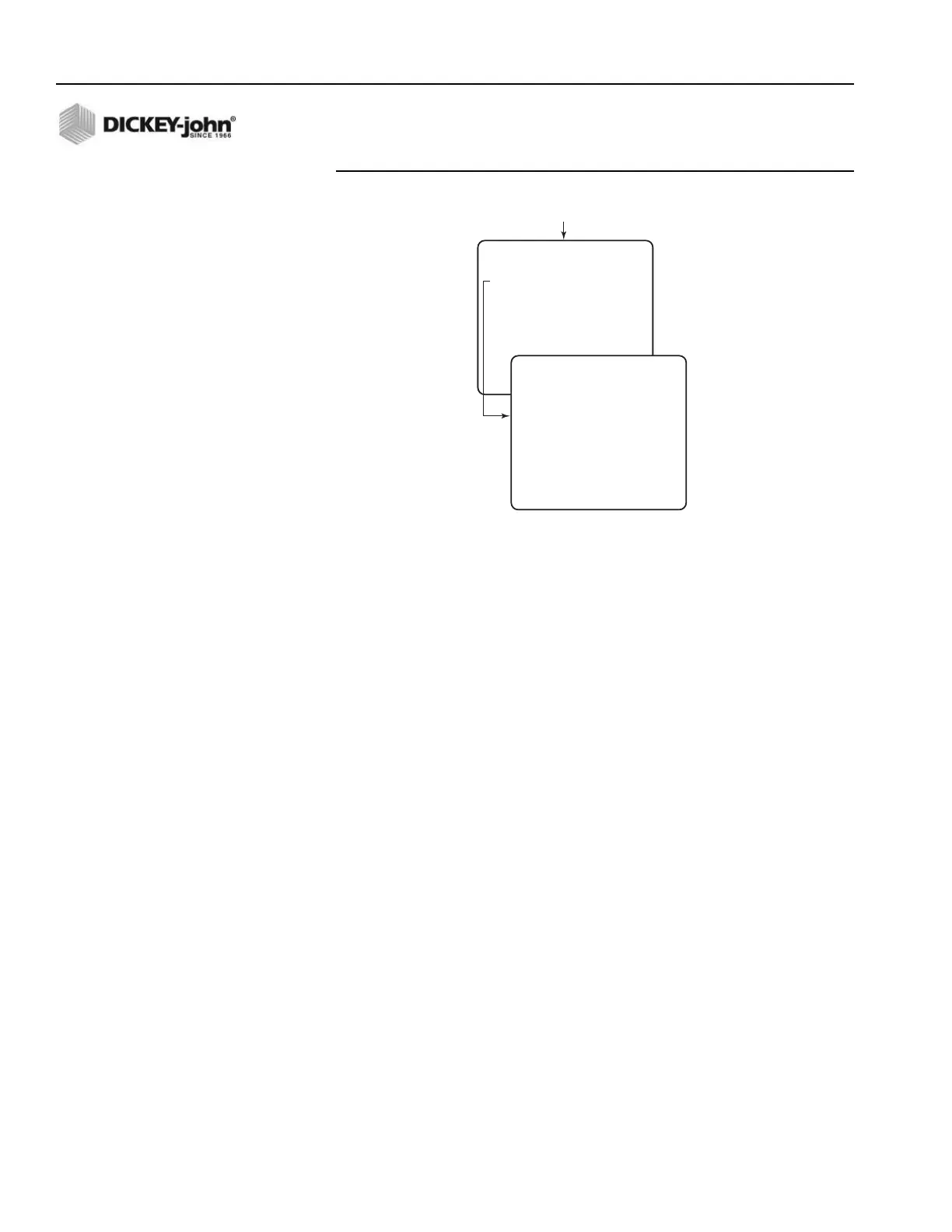

SALT CONFIGURATION

SPR CON 80.0 P/LB

CAL GT HGT 7.4 IN

DRV FREQ 100 HZ

PWM OFFSET 14

PWM SAT 70

SYS RSPNS 11.25

VALV BOOST 2.0

AFILT 0.250000

Loading...

Loading...