OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

INTRODUCTION / 3

INTRODUCTION

The DICKEY-john Control Point

®

system uses three-channels (three

separate controlled servo loops) on spreader vehicles to simultaneously

control the spreading of granular and liquid ice-control materials. Two

channels control granular and liquid application rates and the third channel

precisely controls spinner speed to maintain even material coverage over

the desired spread width. The dispensing rate varies directly with ground

speed to ensure accurate product application.

Material can also be spread at a preset “BLAST” application rate. This is

normally a very large rate to instantly adjust the target APR (application

rate) coverage for bridges and intersections with a much heavier amount of

material.

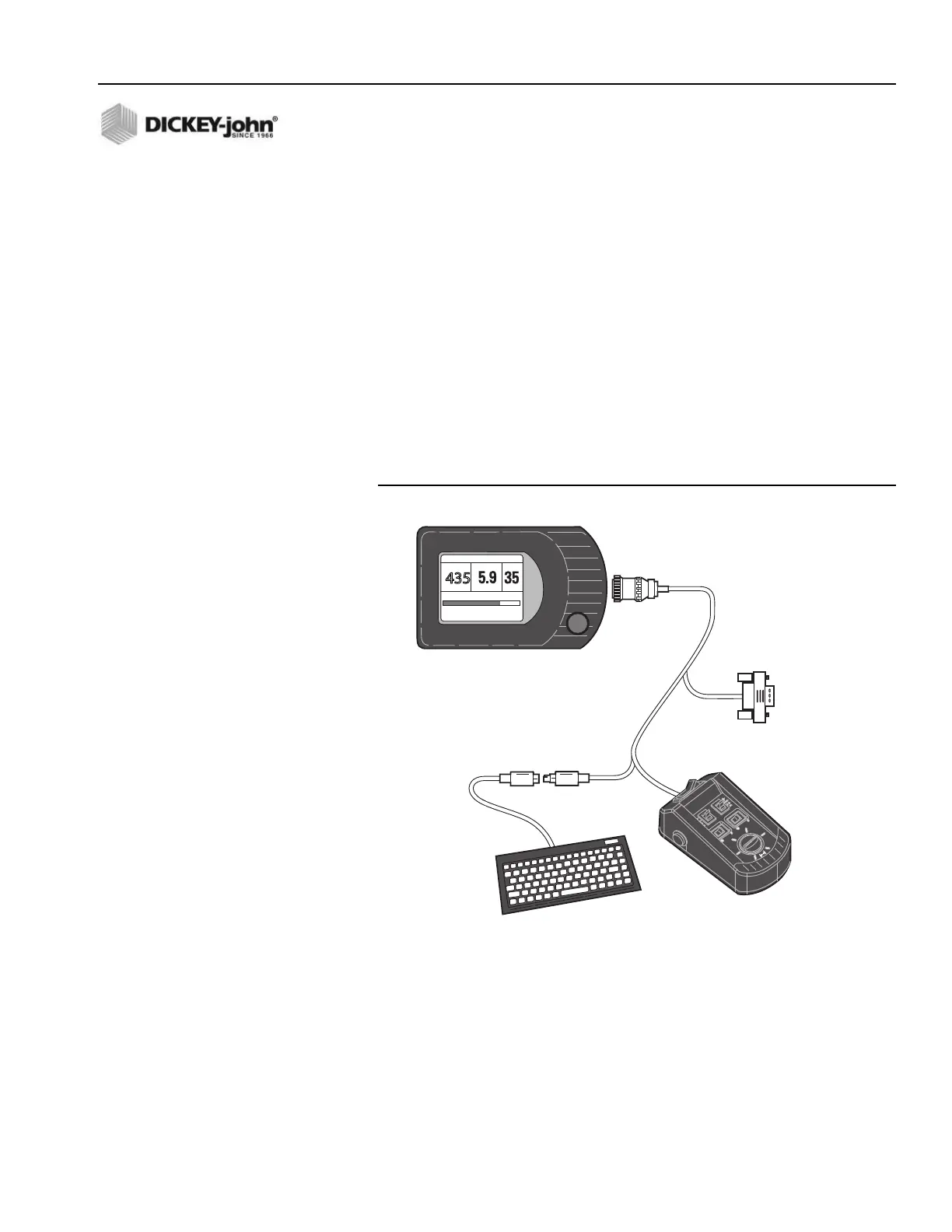

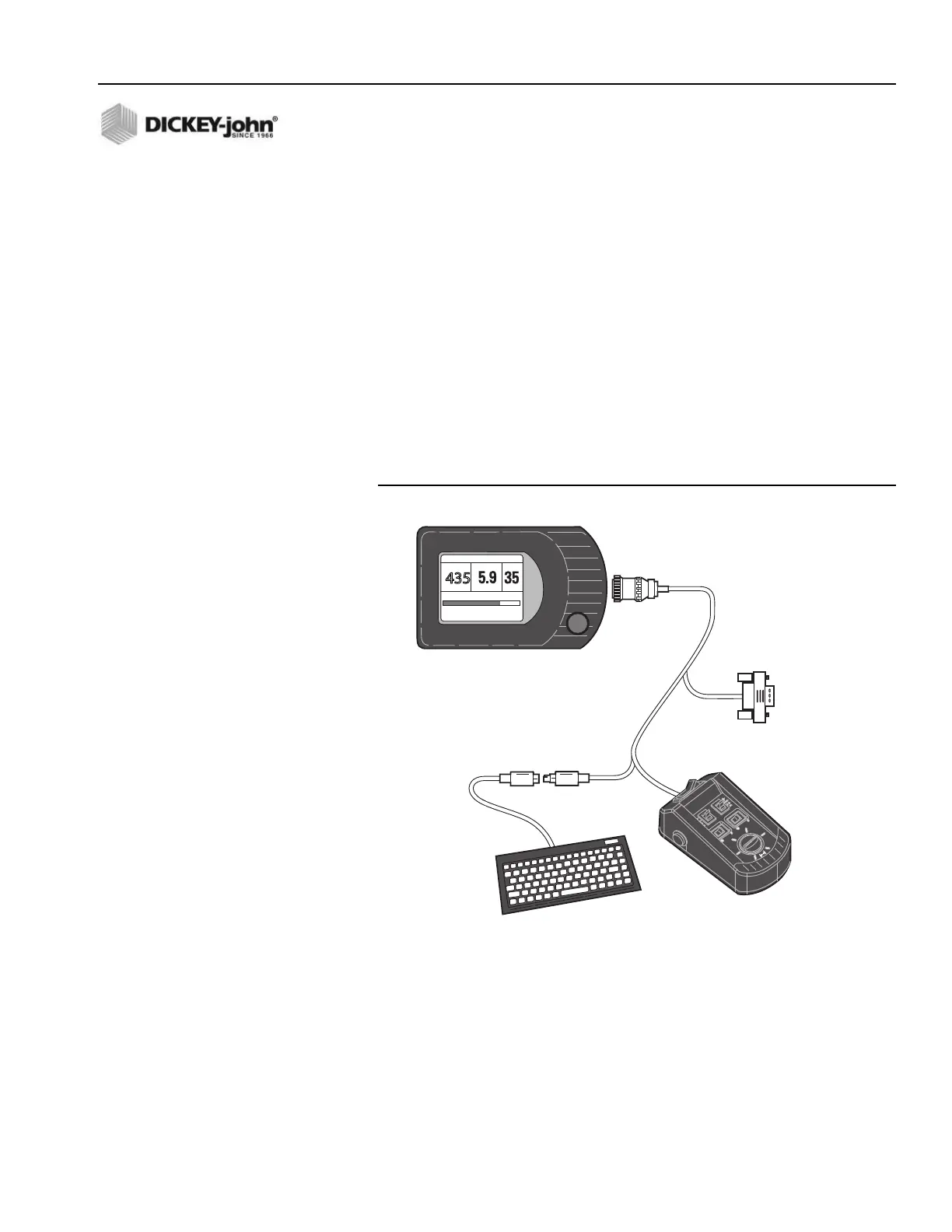

Figure 1 illustrates the Console, Switch Module, and Keyboard.

Figure 1

System Components

GRANULAR CHANNEL CONFIGURATION

The granular channel controls the amount of material dumped onto the

spinner plate(s). The Control Point

®

monitors a tachometer-style feedback

sensor located on the V-box drag chain or tailgate auger. A resultant drive

signal adjusts the conveyor mechanism speed to deliver the target

application rate (APR) by regulating the hydraulic valve position.

435

SALT

LBS/MILE

LIQUID

GAL/TON

MPH

0% 100%

SPREAD WIDTH

8 MAR

12:25:PM

1

2

3

4

5

6

7

8

9

0

-

=

Q

W

E

R

T

Y

U

I

O

P

[

]

\

A

S

D

F

G

H

J

K

L

;

'

Back

Space

Z

X

C

V

B

N

M

,

.

/

RS232

Connector

for

Computer

Display Console

Keyboard

Connectors

Switch

Module

Keyboard

Connects to

Rear side of Console

OFF AUTO UNLOAD

MASTER

0

0

40

60

80

100

BLAST

Loading...

Loading...