OPERATOR’S MANUAL

Control Point

®

11001-1489-201702 Rev B

TROUBLESHOOTING / 87

TROUBLESHOOTING

The Control Point

®

system contains six basic components, each with a

specific function. Component failures normally react in predictable ways,

making fault isolation relatively easy. If certain components are not

operating properly, such as a hydraulic pump or motor, system performance

is degraded and the console may incorrectly appear to be at fault.

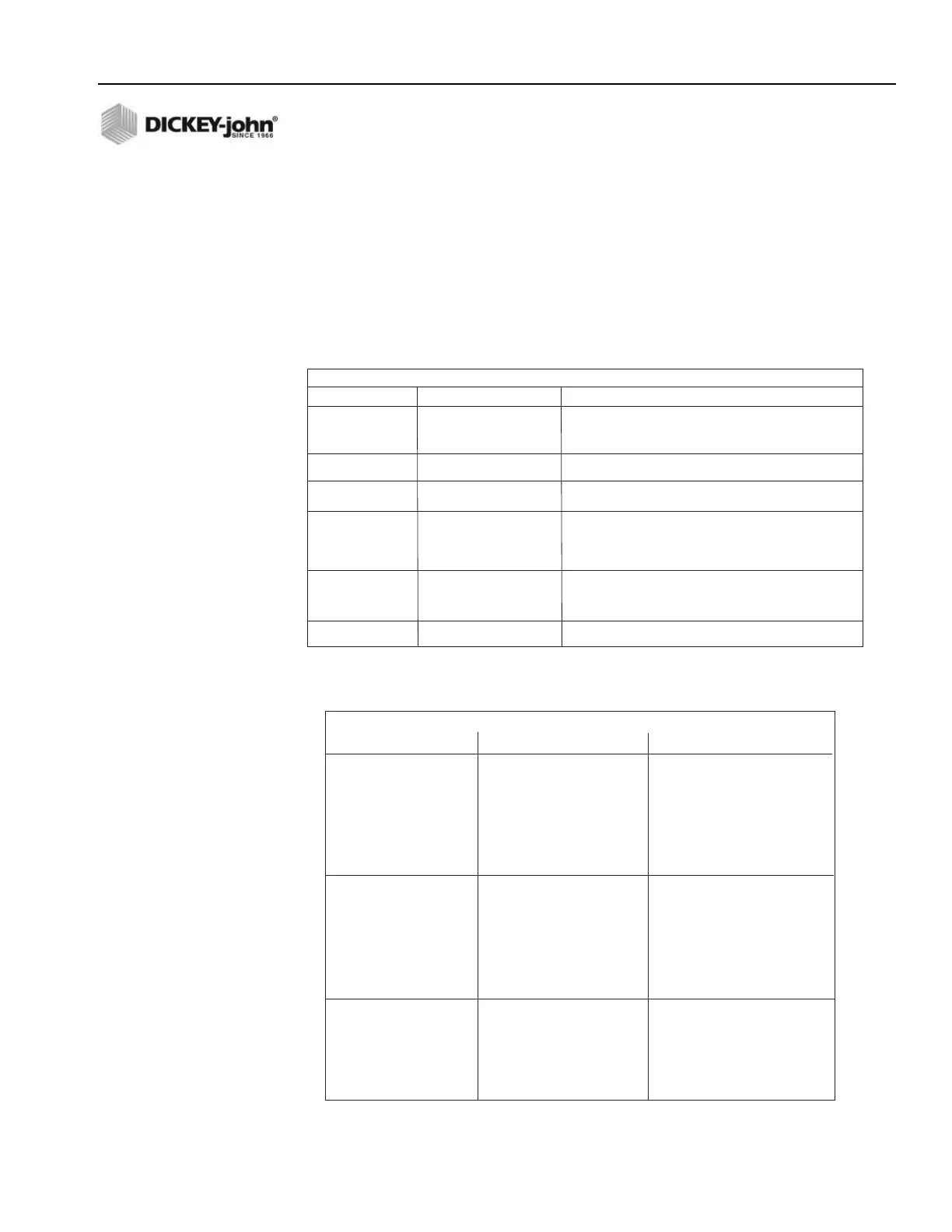

Table 1. Component Interconnections

Component Connected To Function

Console 12VDC vehicle battery Compares vehicle ground speed to conveyor/auger

and all components of and liquid pump speeds and controls the hydraulic valves

control system. (or DC motor for liquid) for the desired application rates.

Switch Module Console Provides operator controls for system real-time functions.

Vehicle Ground Mechanical or Indicates vehicle ground speed to console.

Speed Sensor electronic speedometer.

Sensors for Conveyor/auger and Indicate conveyor/auger speed, spinner speed, and liquid flow

Application Rate spinner or related and Spinner Speed rate or pressure to Console.

hydraulic motor shafts,

plumbing after liquid pump.

Actuators for Servo Conveyor/auger and spinner Regulate conveyor/auger speed,

or Proportional Valves hydraulic control valves and spinner speed, and liquid flow

and Liquid Pump liquid pump. rate.

Harnesses All components Connect all components.

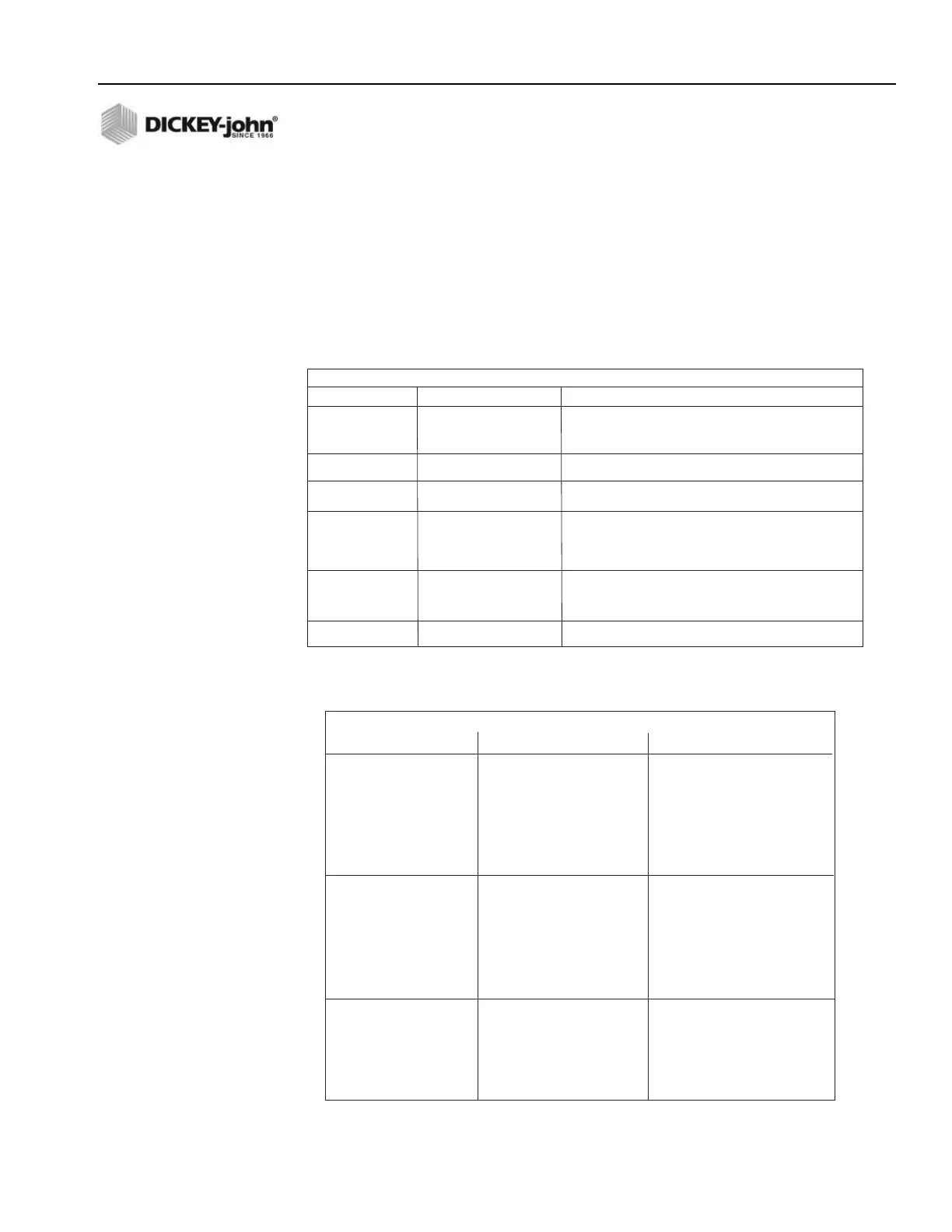

Table 2. Common Spreader Problems (Control System Normal)

Symptom Probable Cause Corrective Action

Conveyor/auger does not 1. Hydraulic pump off. 1. Engage pump.

run in either AUTO or 2. Manual valve closed. 2. Open valve.

UNLOAD 3. Hydraulic quick-connector 3. Reconnect.

loose.

4. Conveyor/auger jammed 4. Clear jam.

5. Relief valve operating at 5. Adjust or replace.

low pressure.

6. Loss of hydraulic oil. 6. Repair leak and refill oil.

Convey/auger does not 1. Faulty hydraulic system. 1. Repair hydraulic system.

reach maximum speed 2. Conveyor/auger binding. 2. Eliminate binding.

3. Relief valve defective or 3. Adjust to proper pressure

set lower than specified. or replace valve.

4. Material lumping and 4. Clear.

jamming conveyor/auger.

5. Engine RPM low because 5. Shift to lower gear

using wrong gear or axle. and/or axle.

Inaccurate application 1. Material density changed 1. Repeat Granular Calibration.

(APR error exceeds 10%) from original calibration.

2. Feed-gate setting changed. 2. Set gate to position used

during Granular Calibration.

3. Inaccurate ground speed 3. Repeat Ground Speed

input because tire size or Calibration.

axle ratio has been changed.

Loading...

Loading...