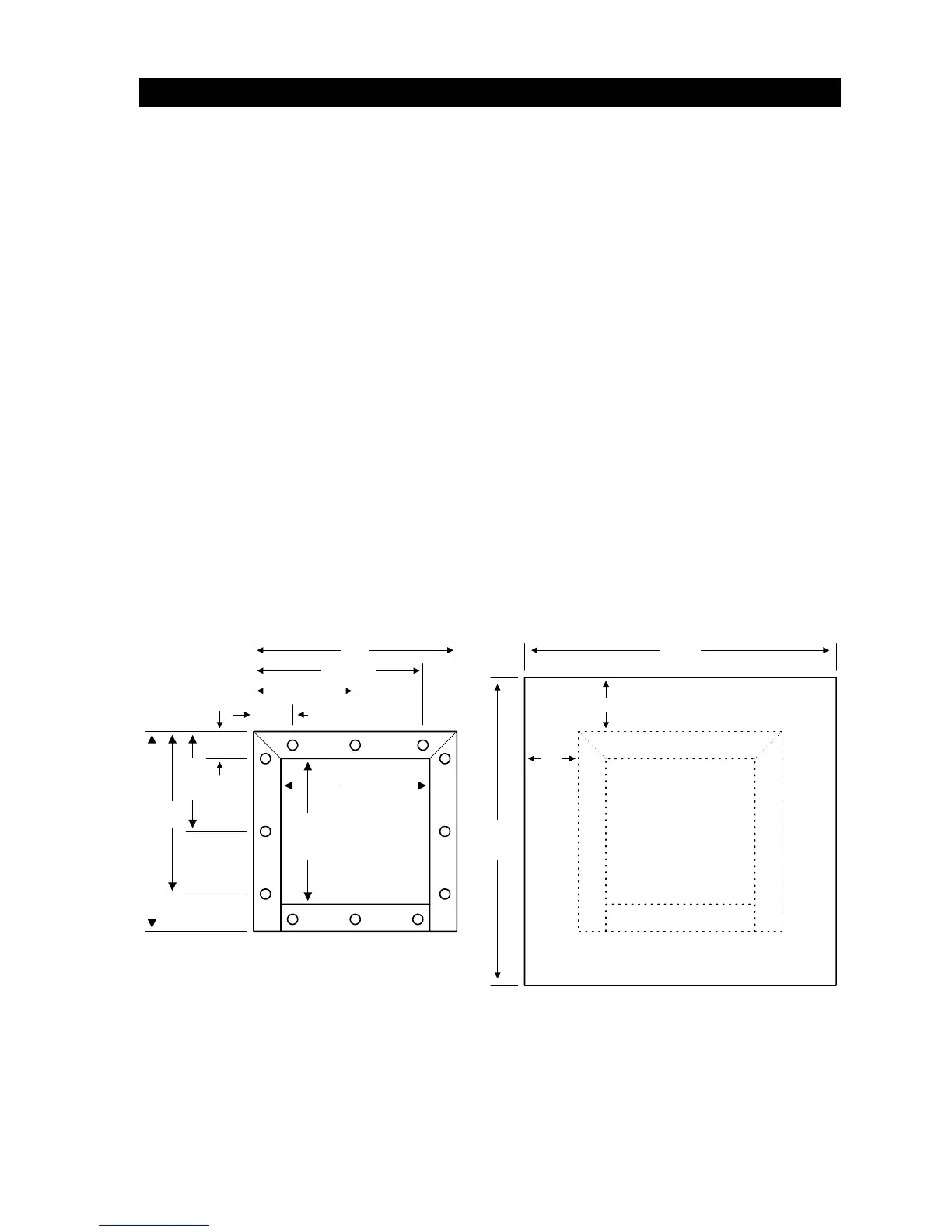

1.3 PAD CONSTRUCTION

The 1601 and 1602 operators are designed to be mounted directly to a concrete pad. The size of the

pad specified below will allow four inches of clearance around the operator. This will prevent the pad

from splitting or cracking when anchoring the operator to the pad.

1. Construct a form for the mounting pad according to the figures shown in the diagram

below. Be sure to level the top edge of the form. The depth of the pad is determined by

local soil conditions and local building codes, but should be at least 24 inches deep. We

suggest that you contact the local building department to determine the proper depth of

the pad.

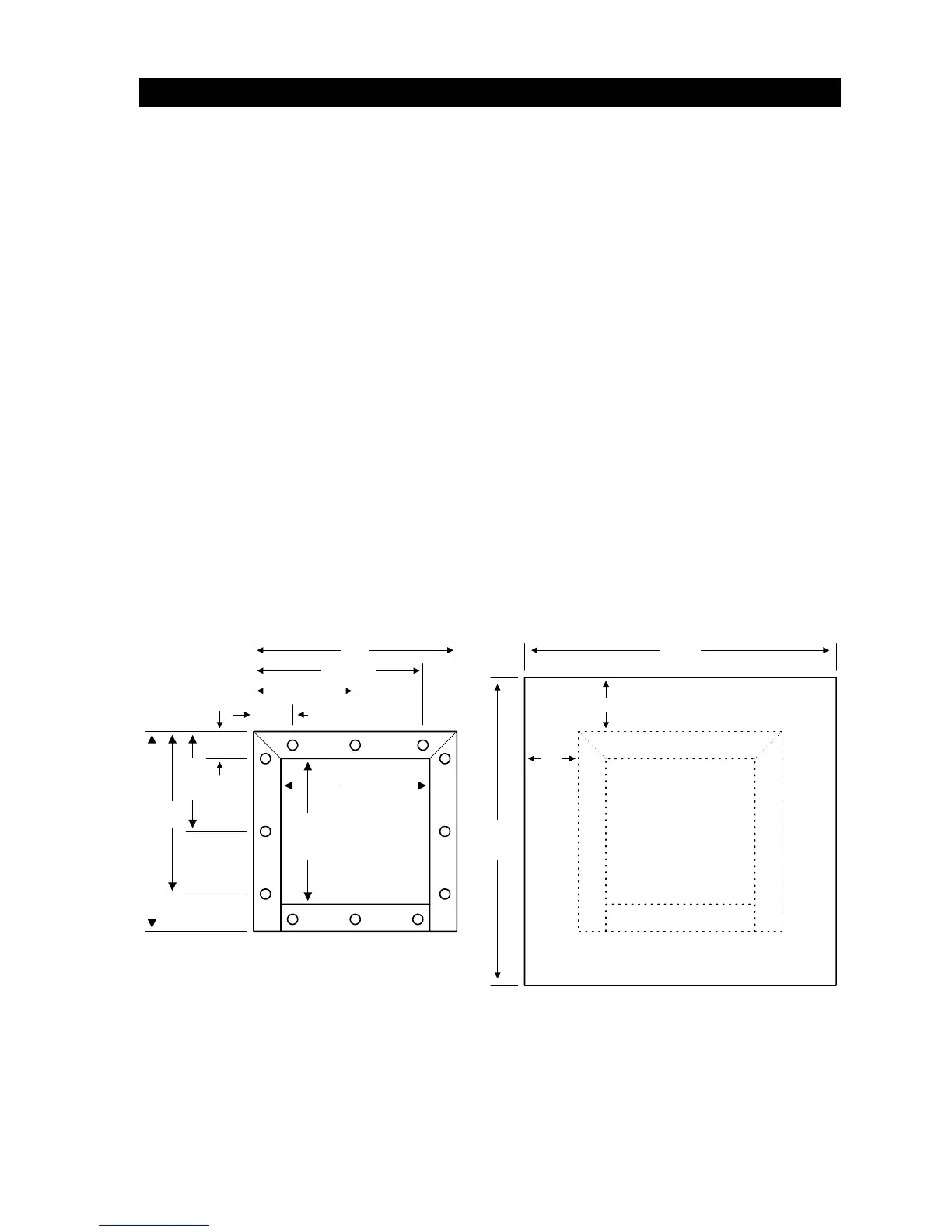

2. Construct the form so that the top level of the pad is at least four inches above ground

level. This will help prevent water from accumulating in the bottom of the operator.

3. Set conduits to center of pad (see below) and reinforcing bars and/or wire mesh if

desired. The number of conduits is determined by the application requirements. Four

conduits are shown below - one for high voltage power, one for low voltage control

requirements, one for loop lead-in wiring, and one for sequencing control wiring or

master/slave application.

4. Mix concrete according to the manufacturers instructions. Pour the mixture into the form

and tamp. Level and finish the surface after pouring is complete. Do not set anchor bolts

in the concrete. Sleeve anchors can be used to anchor the operator to the concrete after

it has hardened and will allow you to position the operator on the pad exactly where you

want it.

5. Allow the pad to cure for 48 hours before removing the forms or mounting the operator.

11

10.75

14.75

12

7.25

2.5

2.625

7.5

12.375

15 23

23

Base Detail

Mounting Holes

Mounting Pad

4

4

Figure 3

11

Loading...

Loading...