SECTION 4 – ARM AND ACCESSORY INSTALLATION

Prior to installing the arm(s) onto the shaft of the barrier operator, the direction of rotation of the

output shaft must be checked. The direction of rotation to raise the arm to the up position is

dependent on how the operator has been installed (door of the operator opposite the traffic lane, or

door of the operator facing the traffic lane), and if the operator has been installed on the left or right

hand side of the traffic lane. It is important that the output shaft rotation be checked BEFORE

installing the arm(s) onto the operator. If the output shaft rotation is in the opposite direction for

your particular application and the arm(s) has been installed prior to checking the rotation direction,

damage to both the arm(s) and the operator may result when the operator is placed in service.

4.1 ARM INSTALLATION

4.1.1 DIRECTION CHECK

1. Turn power to the barrier operator ON and momentarily place the control toggle switch to

the UP position. When the operator starts, note the direction of rotation of the output

shaft. If the shaft rotates in the right direction, proceed to section 4.1.2, 4.1.3 or 4.1.4. If

the shaft rotates in the wrong direction, continue with step 2 in this section.

2. Turn power to the operator OFF.

3. Remove the plastic cover from the 1601-010 circuit board.

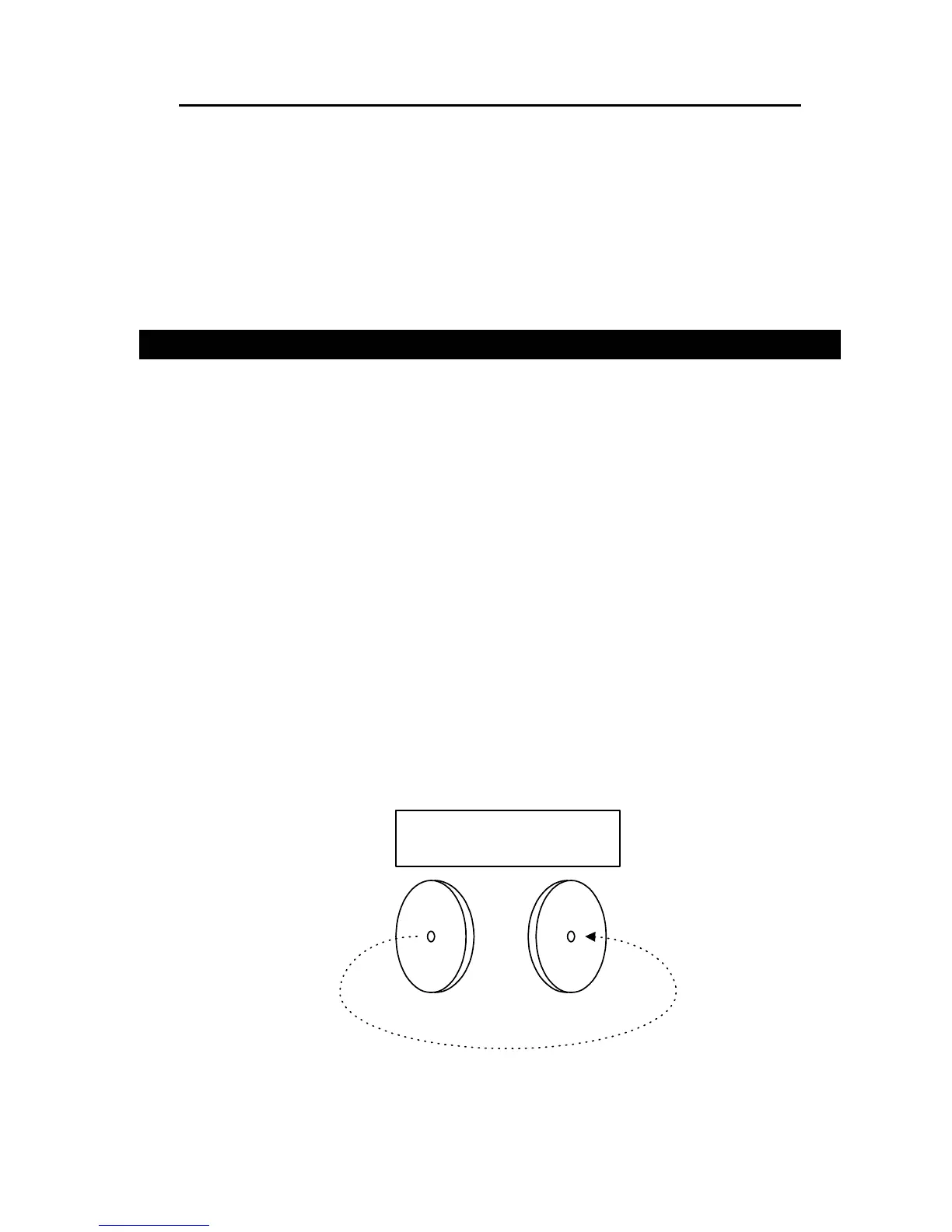

4. Flip the magnet over. NOTE: Each magnet has a small indent on one side. If the indent

is facing out, flip the magnet so that it is facing in, or if the indent is facing in, flip the

magnet so that it is facing out.

5. Manually turn the drive pulley so that the other magnet rotates to a position where it is

accessible.

6. Flip this magnet over. NOTE: Each magnet has a small indent on one side. If the indent

is facing out, flip the magnet so that it is facing in, or if the indent is facing in, flip the

magnet so that it is facing out. IMPORTANT!! One magnet must have the indent

facing out and one magnet must have the indent facing in.

7. Replace the plastic circuit board cover and repeat step 1 to check shaft rotation.

Rotate UP and DOWN magnets

180º to change rotation of shaft.

Figure 23

35

Loading...

Loading...