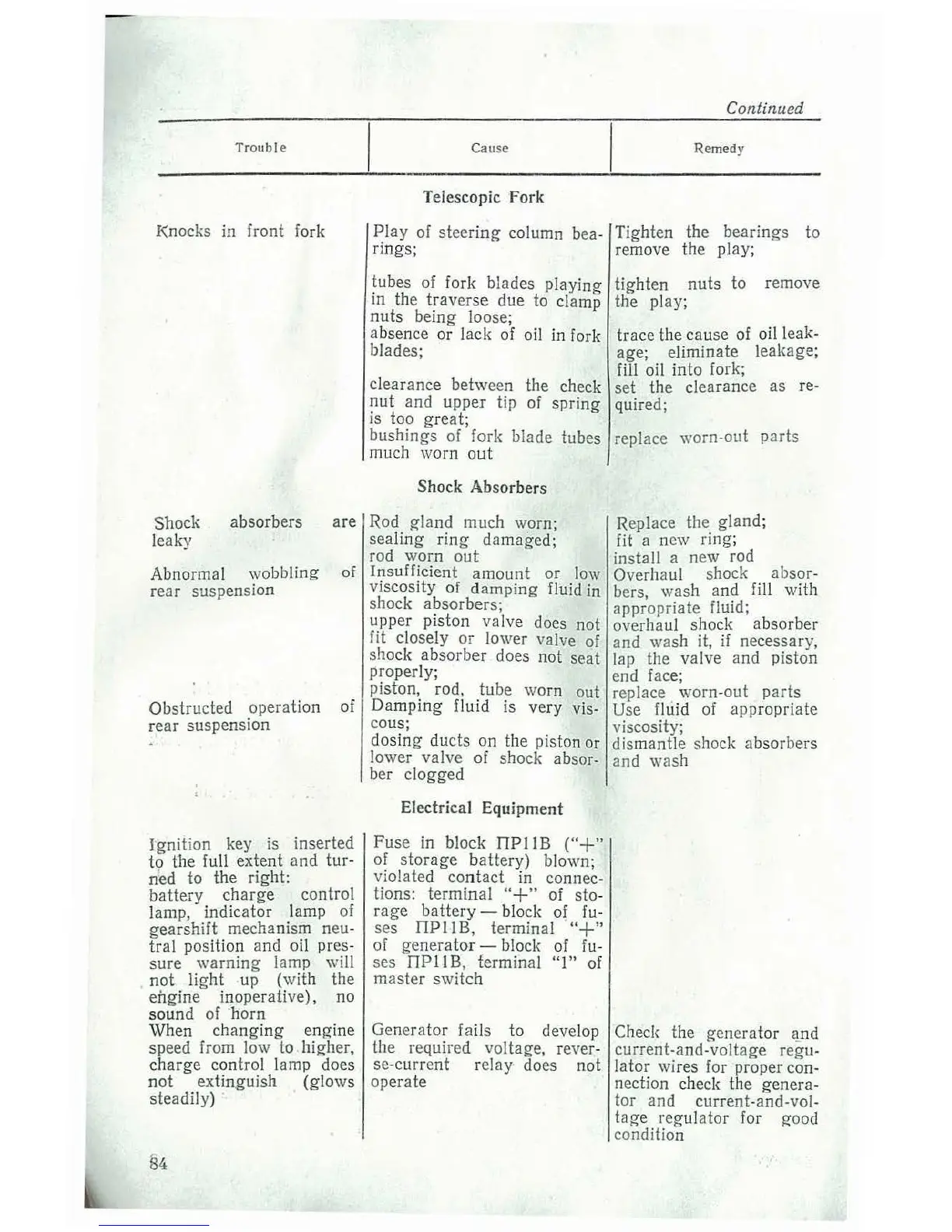

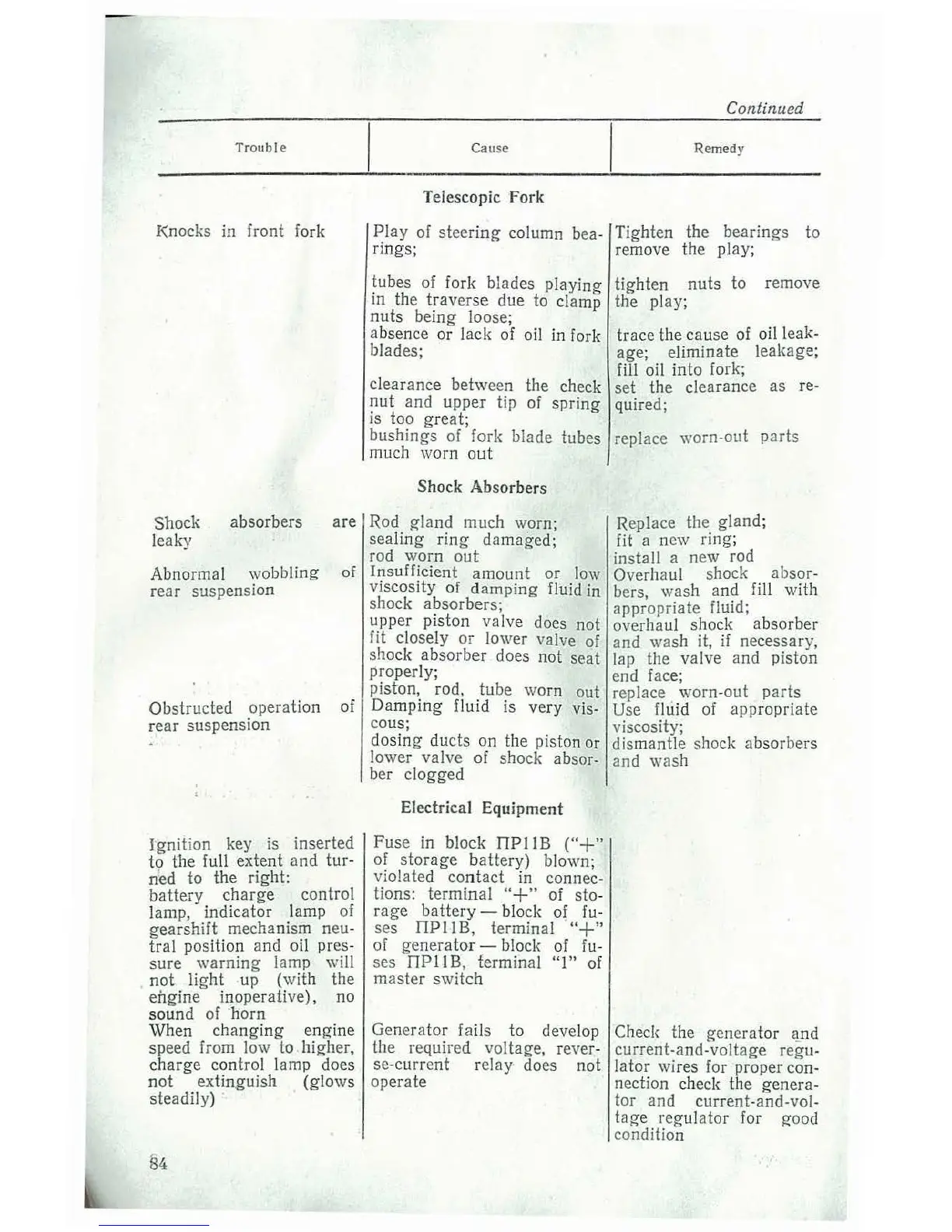

Continued

Trouble

Cause

Remedy

Telescopic

fork

Knocks in front fork

Play

of

steering

column bea- Tighten

the

bearings

to

rings; remove the play;

tubes of fork blades playing

in the

traverse

due to clamp

nuts

being loose;

absence

or

lack

of oil in fork

blades;

clearance between

the

check

nut

and

upper

tip of

spring

is too

great;

tighten

nuts

to

the play;

remove

trace

the

cause

of oil leak-

age; eliminate leakage;

fill oil into fork;

set

the

clearance

as

re

-

quired;

bushings

of fork blade tubes replace worn-out

parts

much worn

out

Shock Absorbers

Shock

absorbers

leaky

are

Rod

gland

much worn;

sealing

ring

damaged;

rod

worn

out

Abnormal wobbling

rear

suspension

of Insufficient

amount

or

low

viscosity of

damping

fluid

in

shock

absorbers;

upper piston valve does

not

fit closely

or

lower valve of

shock absorber does not

seat

properly;

Obstructed

operation

rear

suspension

piston, rod, tube

worn

out

of

Damping

fluid is

very

vis-

cous;

Ignition

key is inserted

to

the

full

extent

and

tur-

ned

to the right:

battery

charge

control

lamp, indicator lamp of

gearshift

mechanism neu-

tral

position

and

oil pres-

sure

warning

lamp will

not

light

up (with

the

engine

inoperative). no

sound

of horn

When

changing

engine

speed from low to higher,

charge

control lamp does

not

extinguish

(glows

steadily)

dosing

ducts

on

the piston or

lower valve of shock absor-

ber clogged

Electrical Equipment

Fuse

in block

DPliB

("+"

of

storage

battery)

blown;

violated

contact

in connec-

tions:

terminal

"+"

of

sto

-

rage

battery-

block

o~

fu-

ses

TIPllB,

terminal

"+"

of

generator-

block of fu-

ses

DPIIB,

terminal "1" of

master

switch

Generator fails

to

develop

the

required voltage, rever-

se-current relay does

not

opera

te

Replace the

gland;

fit a new ring;

install a new rod

Overhaul shock absor-

bers

wash

and fill

with

app;opriate fluid;

overhaul shock absorber

and

wash it, if necessary,

lap the valve

and

piston

end face;

replace

worn-out

parts

Use fluid of appropriate

viscosity;

dismantle shock absorbers

and

wash

Check

the

gene

rator

1!_

nd

current

-and-volt

age

regu-

lator wires for proper con-

nection check the genera-

tor and current-and-vol-

tage

regulator

for good

condition

Loading...

Loading...