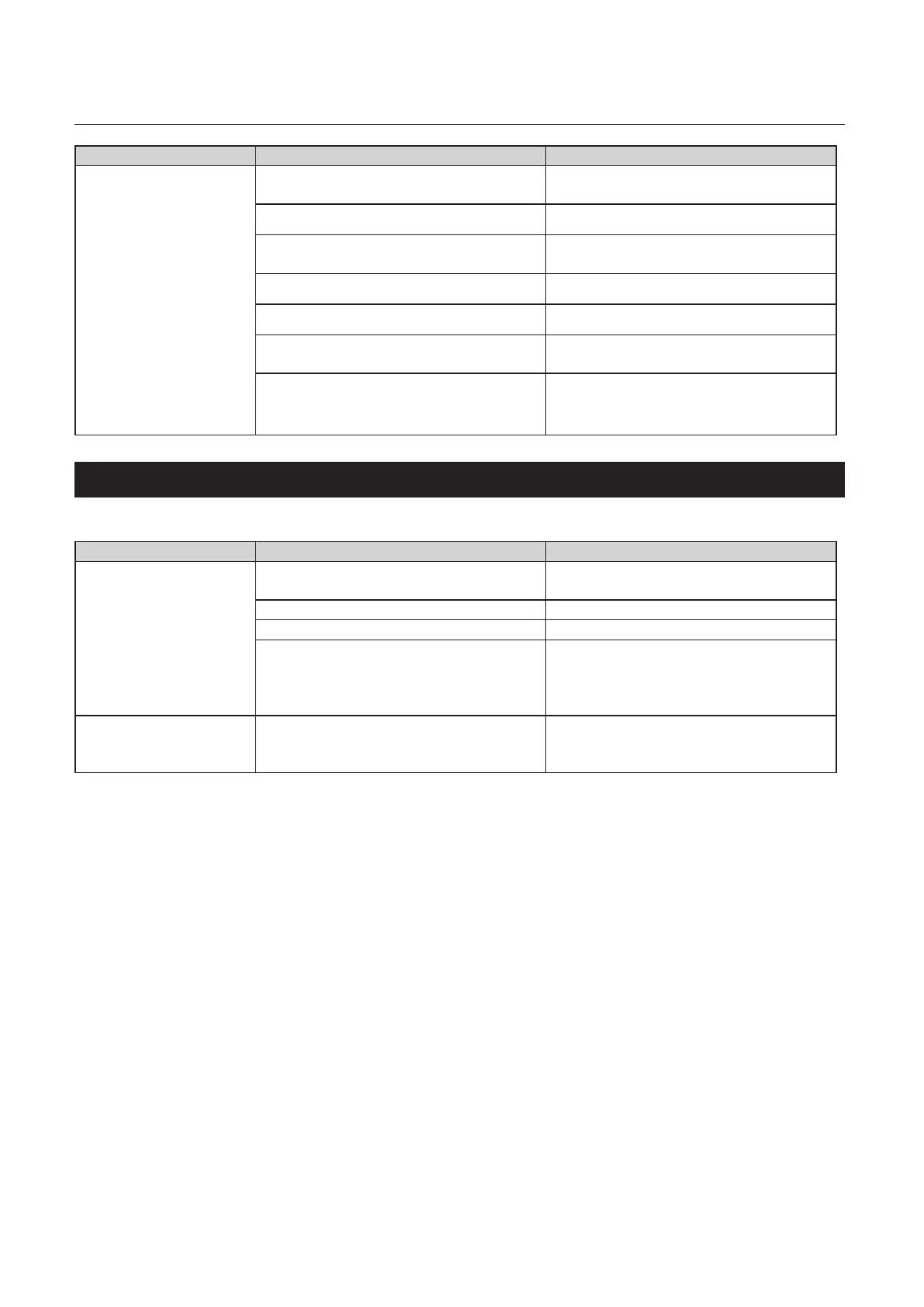

5-12

Chapter 5 Trouble Guide

Symptom Cause Solution

Paper is not conveyed

from the stitching section

to the folding section.

The height or the stitch ejection roller R is

not correct.

Adjust the height.

(p.2-38)

The stitch ejection roller R is not attached. Attach the stitch ejection roller R unit.

(p.2-35)

The stitching side guides are set too close

to each other.

Set the stitching side guides distant from

each other.

(p.2-21)

The stitch ejection roller R is set to o. Set it to on.

(p.1-27)

The stitch ejection roller L is set to o. Set it to on.

(p.1-27)

A stitch is deformed and is stuck on the

conveyance surface.

Adjust each section of the stitcher head.

(p.4-4)

The gap between the stitching paper

holder and the conveyance guide is too

narrow for the paper thickness.

Widen the gap.

(p.2-37)

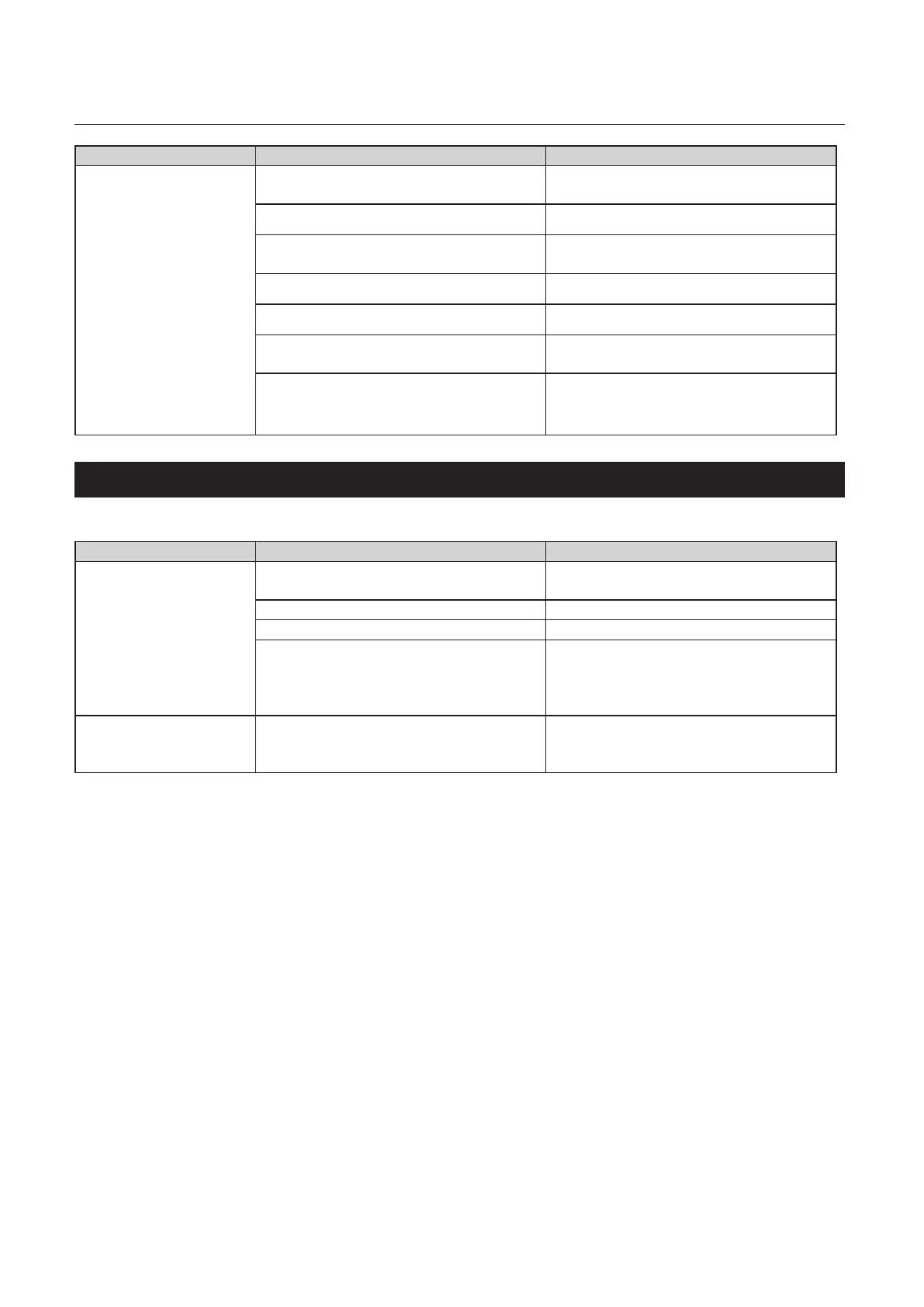

4-3. DBM-600 folding section

Symptom Cause Solution

Paper strikes against the

folding side guide and

paper jams.

Paper is conveyed skewed and strikes

against the folding side guide.

Slower the stitching side guide opening

timing.

(p.1-26)

The stitch ejection roller L is set to o. Set it to on.

(p.1-27)

The folding back guide unit is not secured. Secure the folding back guide unit.

(p.5-7)

When the OFFSET TRIM KIT (option) has

been attached, the folding side guides are

not adjusted according to the oset trim

amount.

Check the amount displayed on the control

panel and manually move the folding side

guides.

(p.2-14)

Paper does not reach

the folding stopper and

paper jams.

The space under the fold paper holder is

too narrow for the paper thickness.

Widen the space.

(p.2-40)

Loading...

Loading...