MAINTENANCE, SERVICE AND FAULT FINDING

4-4 25364 Issue 8 March 2018

Maintenance Schedule

The Compact 32d, 32c, 53c and Communicator II do not require

component replacement as part of a preventative maintenance routine. We

recommend regular checks to ensure optimum performance is maintained

and to allow any parts requiring future replacement to be identified early.

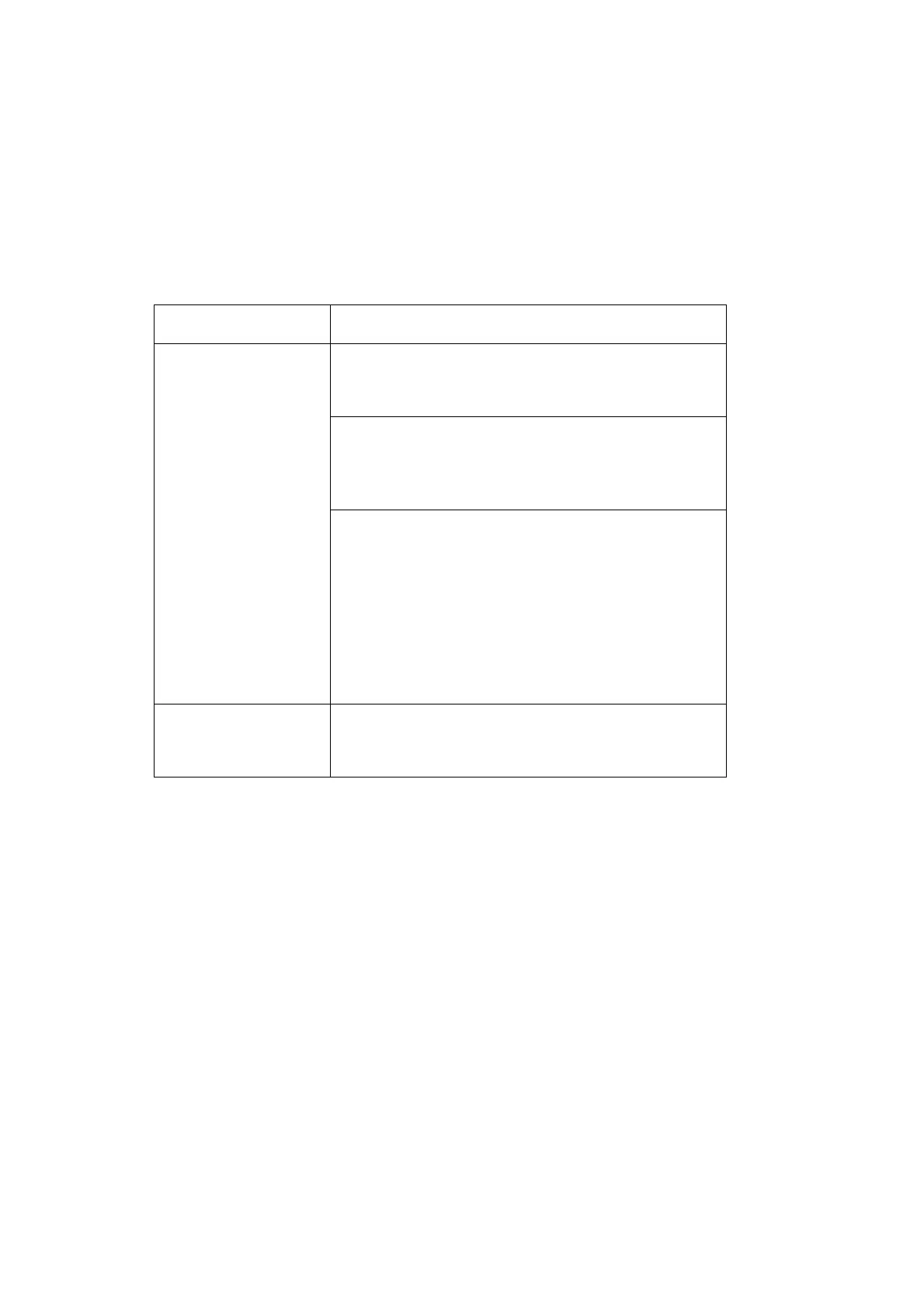

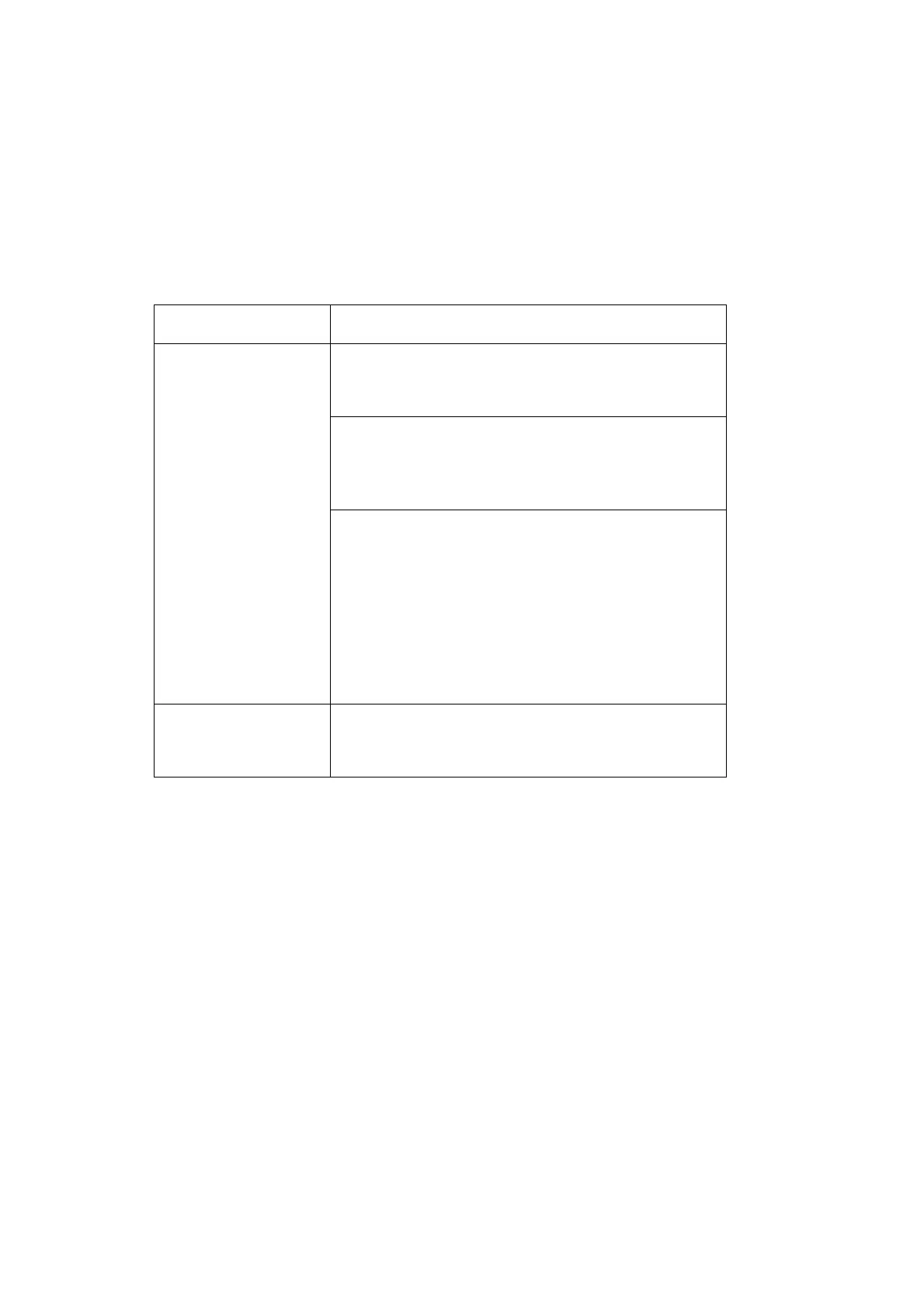

Maintenance Schedule

Frequency Recommended Actions

Regularly

(or if print quality

deteriorates)

Check condition and clean Print Head and

Rubber capstan roller each time the ribbon is

replaced (or at least once per day).

Check condition of the rubber platen / rubber

roller within the printer bracket. the rubber

surface must be smooth, flat and free of debris.

This should be a weekly check.

As part of any fault finding routine, check that

settings such as ‘Contrast’ and ‘Print Head

Pressure’ have not been modified in away from

the original values. Once set, these settings do

not generally need to be changed. Any changes

may have been made to compensate for other

problems. For example, the contrast or pressure

settings may have been set higher to compensate

for a print head that needs cleaning.

Every Year Check condition of the Ribbon guide rollers

(including those on the dancing arms). Check that

the plastic rollers rotate smoothly.

Loading...

Loading...