Version 2.02 15.05.2007

Function of VS 3000

23

eckelmann.de

E 2007 - ECKELMANN AG | BERLINER STRASSE 161 | 65205 WIESBADEN | TELEFON +49(0)611 71 03-0 | FAX +49(0)611 71 03-133

2 (compressor with two capacity stages) and - depending on the number of compressors - Capacity Stage 3

(compressor with two capacity stages).

A corresponding fault report is generated for Compressor 1. When capacity-controlled compressors are added,

the relay contacts for the base load and capacity stages of the second compressor change to stage No.CS per

Comp. + 1 and so on.

A fault on Compressor 2 causes shutdown of the capacity stage (No.CS per Comp. + 1 and so on) and gener-

ation of the corresponding fault report for Compressor 2. Following base load rotation (Base Load Rotation Out-

put ON), a fault on Compressor 1 causes shutdown of the capacity stage (No.cap.stages + 1 and so on) and

generation of the corresponding fault report for Compressor 1.

A fault on Compressor 2 causes shutdown of Capacity Stage 1 and so on and generation of the corresponding

fault report for Compressor 2.

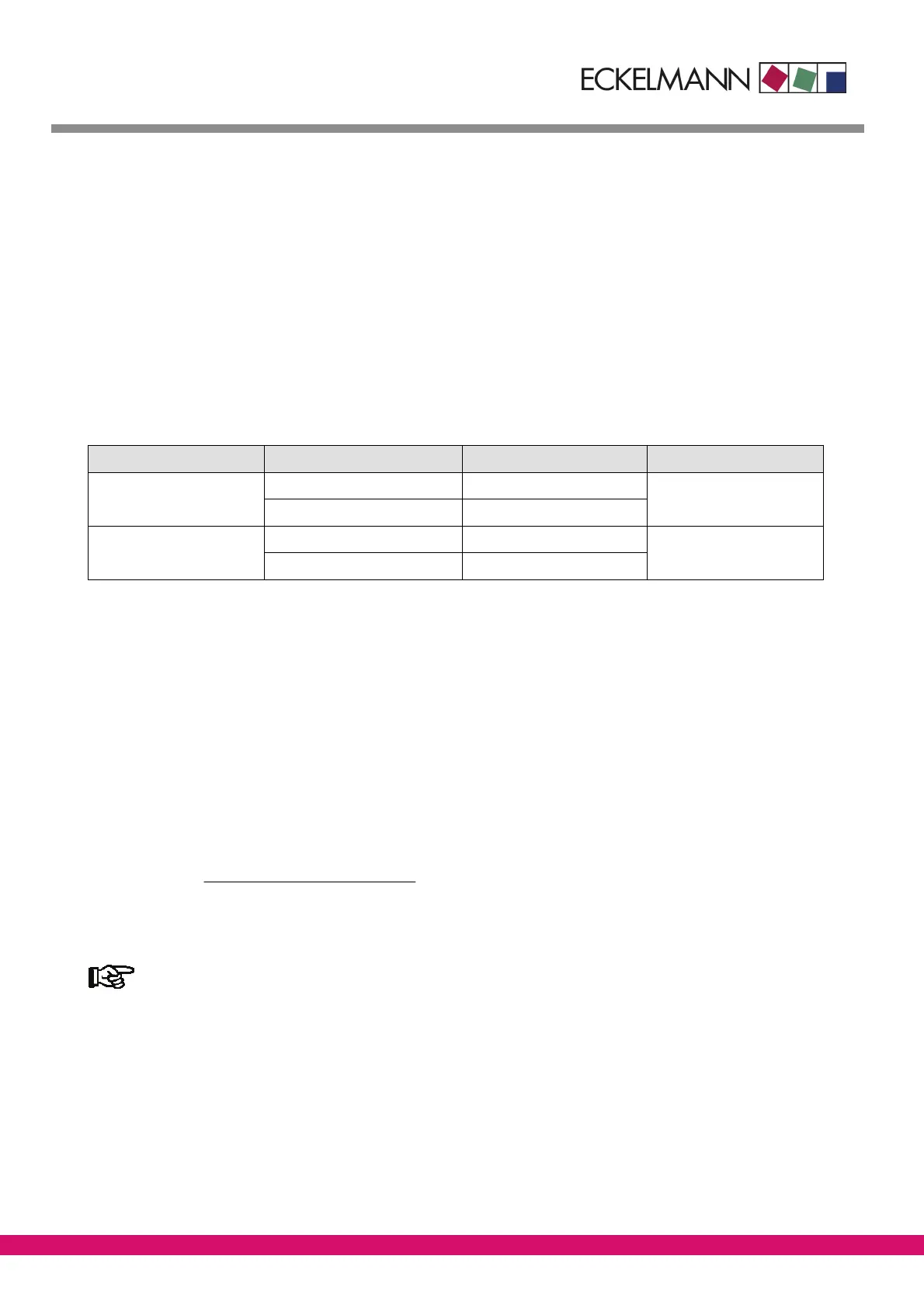

Example: Compressor with three-stage capacity control (No.cap.stages =3)

Fault Base load rotation output Capacity stage output OFF Fault report

Compressor

ON Stage 4, Stage 5, Stage 6

Compressor C1

OFF Stage 1, Stage 2, Stage 3

Compressor

ON Stage 1, Stage 2, Stage 3

Compressor C2

OFF Stage 4, Stage 5, Stage 6

3.23 Monitoring high pressure

High pressure is measured in the high-pressure line by a continuous transmitter delivering an output current/

voltage. Pressure is also monitored by the safety high-pressure cutout and high-pressure cutout. These devices

deliver a digital signal when the set pressure level is exceeded. Both of these digital signals are connected to

the controller in series.

Forced shutdown of all compressors takes place if pressure exceeds the limits set for the safety high-pressure

cutout and high-pressure cutout. A HPCutout alarm is generated. Priority of the alarm can be set by parameter.

The compressors are loaded stagewise after mechanically resetting the pressure cutouts.

No further compressor capacity stages are loaded on exceeding the high limit

tc OFF Comp −

(

tc OFF Comp − tc ON Comp

)

4

and a High tc/HD fault report is generated after a definable delay (parameter Delay tc/HP OFF, Menu 3-3). No

message is generated in heat recovery mode.

When pressure again falls below the high limit, additional compressor stages are only loaded if the tc

OFF Comp. limit (Menu 3-3) has not been not exceeded.

If high pressure rises to a definable limit (Menu 3-3, tc OFF Comp.), compressor stages are unloaded in keeping

with the maximum number of compressor stages. Unloading of compressor stages continues until such time as

further unloading would reduce capacity of the compressor pack to less than 40% or pressure falls below the

limit (Menu 3-3, tc OFF Comp.). One compressor stage is shut down independent of current pack capacity. No

further unloading takes place if it would cause capacity to drop below 40%.

Unloading of the first stage takes place without delay. Additional stages are unloaded on elapse of the basic un-

load time.

After exceeding the high limit tc OFF Comp. (Menu 3-3), additional compressor stages are not loaded until pres-

sure again drops below the enabling level tc ON Comp. (Menu 3-3).

Loading...

Loading...