ADL 2010 / 01 23/57 599 72 63-27

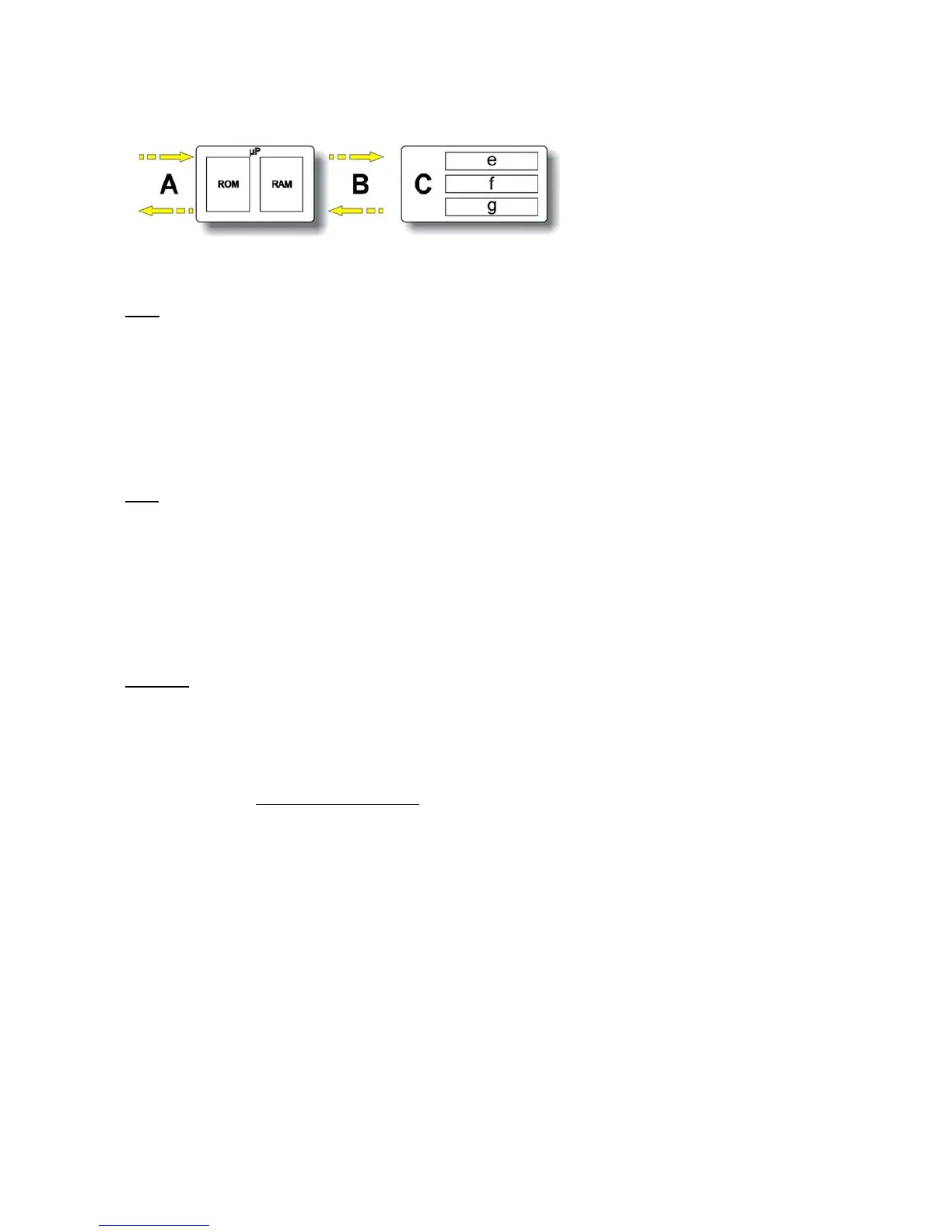

7.1.2 Electronic control memories: general structure

A Asynchronous external serial

port

B Synchronous internal serial port

C EPROM external to the μP

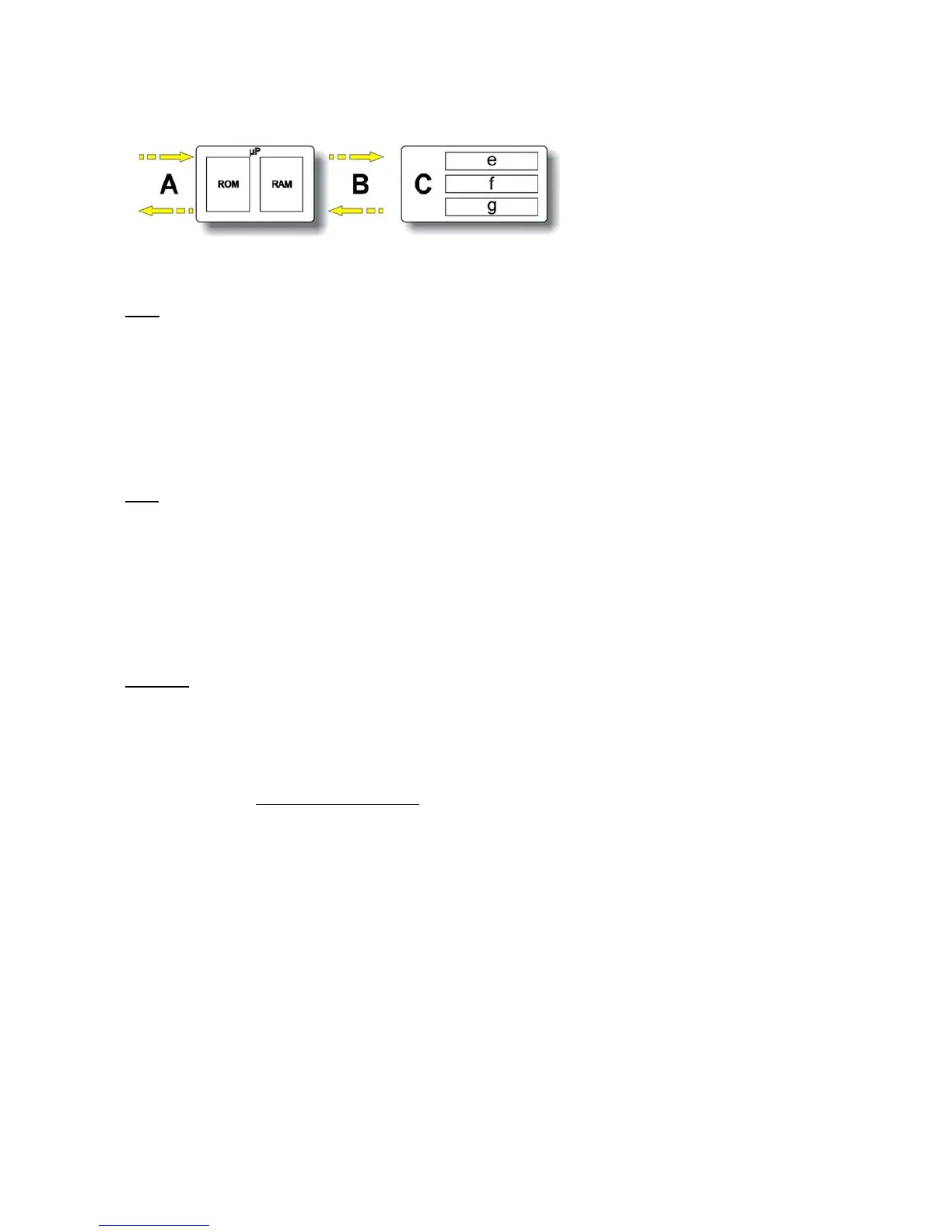

e Power fail and machine status

f Board configuration

g Description of cycle

ROM

This area of the memory contains the "firmware" code comprising the appliance functions:

Ö management of electrical loads (motor, heating unit);

Ö management of sensors (NTC, conductivity sensor, door switch status);

Ö management of the user interface;

Ö management of the serial port;

Ö management of power failures and alarms;

Ö carrying out the drying programme.

In normal appliances this area is of the Read Only Memory type, and therefore cannot be modified.

RAM

This memory contains the variables, that is to say all the dynamic information used during running of the

programme:

Ö Machine status

Ö Cycle selected

Ö Alarms

The memory is deleted every time the power supply stops (in the event of a power failure or when the

appliance is turned off).

The contents of the memory can be read using a computer connected via a DAAS interface.

EEPROM

This memory contains various types of data:

Ö Power fail and machine status, that is to say the information required to start the appliance up again in

the event of a power failure;

Ö Drying cycle configuration: this file describes the various steps in the drying cycle for each family of

appliances (ventilated, condensation, conductivity....);

Ö Machine configuration: data contained in this section of the memory are those that define the

configuration of each individual appliance

and they are interpreted by the operating software. The

following are defined in this file:

- Programmes

- Number and functions of buttons

- LED functions

- Buzzer operation

- Working limits (voltage/frequency)

- Machine identification (PNC + ELC + Serial number)

- Heating unit power

- Preferential direction of rotation of the motor

Loading...

Loading...