ADL 2010 / 01 25/57 599 72 63-27

7.2 Conductivity sensor

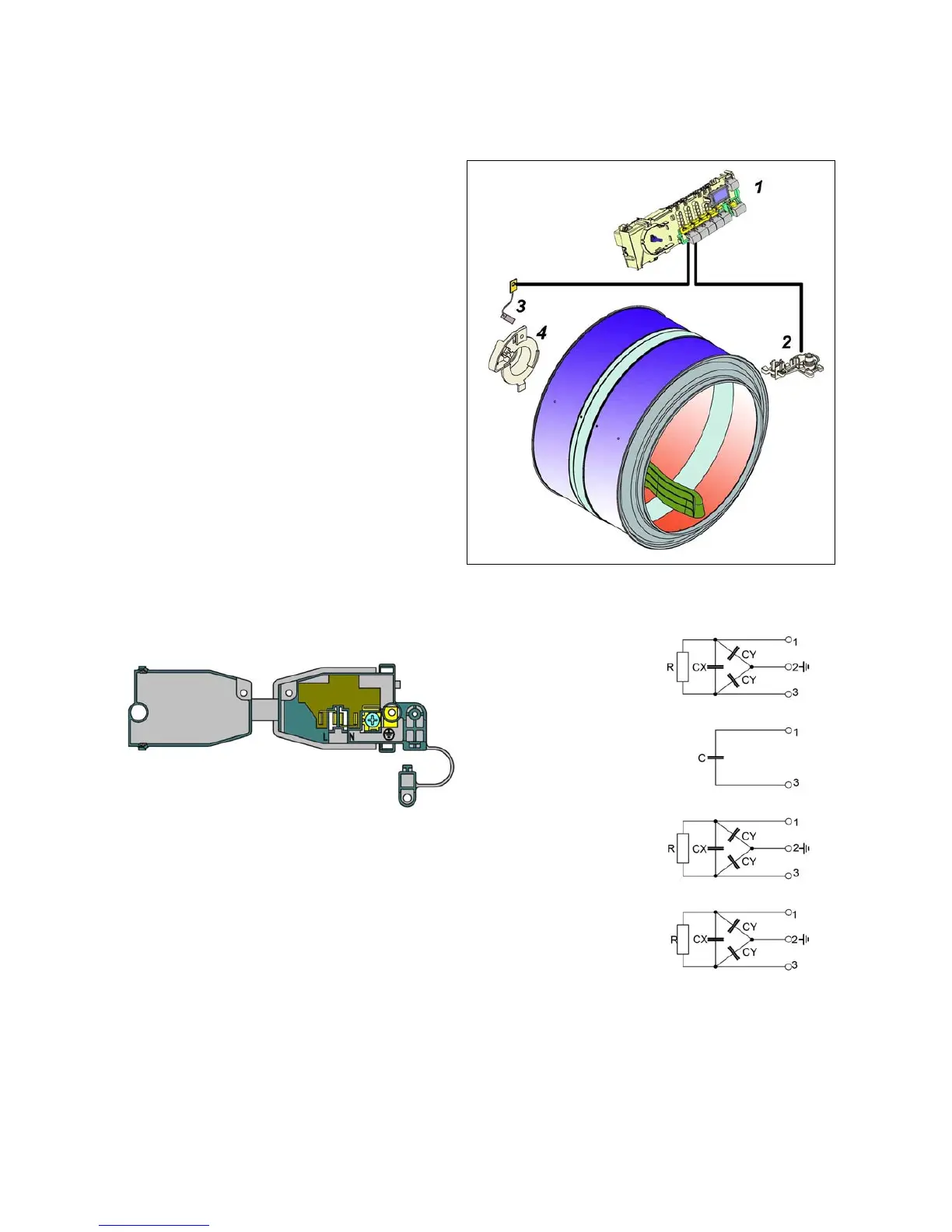

These electronics use a conductivity sensor, comprising an electronic circuit (located inside the main circuit

board) and a part outside the board comprising wiring cables, two brushes (contact sensors for the drum

half-casings) and the two half-casings themselves.

The brush in contact with the front half-casing (2)

is fixed in a swinging support to the conduit, and is

wired to the circuit board; the other brush is in

contact with the drum pin (3) inserted in the drum

pin guard (4); connection of this sensor to the

circuit board (1) takes place via the unit which acts

as the earthing system for the appliance's electonic

circuit.

As the drum is divided into two parts by an

insulating strip, there is an infinite impedence

between the front and rear half-casings (to which

the sensors are connected) when it is empty;

whereas its value is influenced by the load of

washing, the type of fabric and the level of

humidity in the drum.

The impedence value is approximately 1MΩ ÷

25M.ΩThis value is transformed into an oscillation

of ~ 260Hz ÷ 0Hz, which when read and processed

by the electronic circuit (fuzzy logic) determines

the duration and final humidity level for the chosen

cycle.

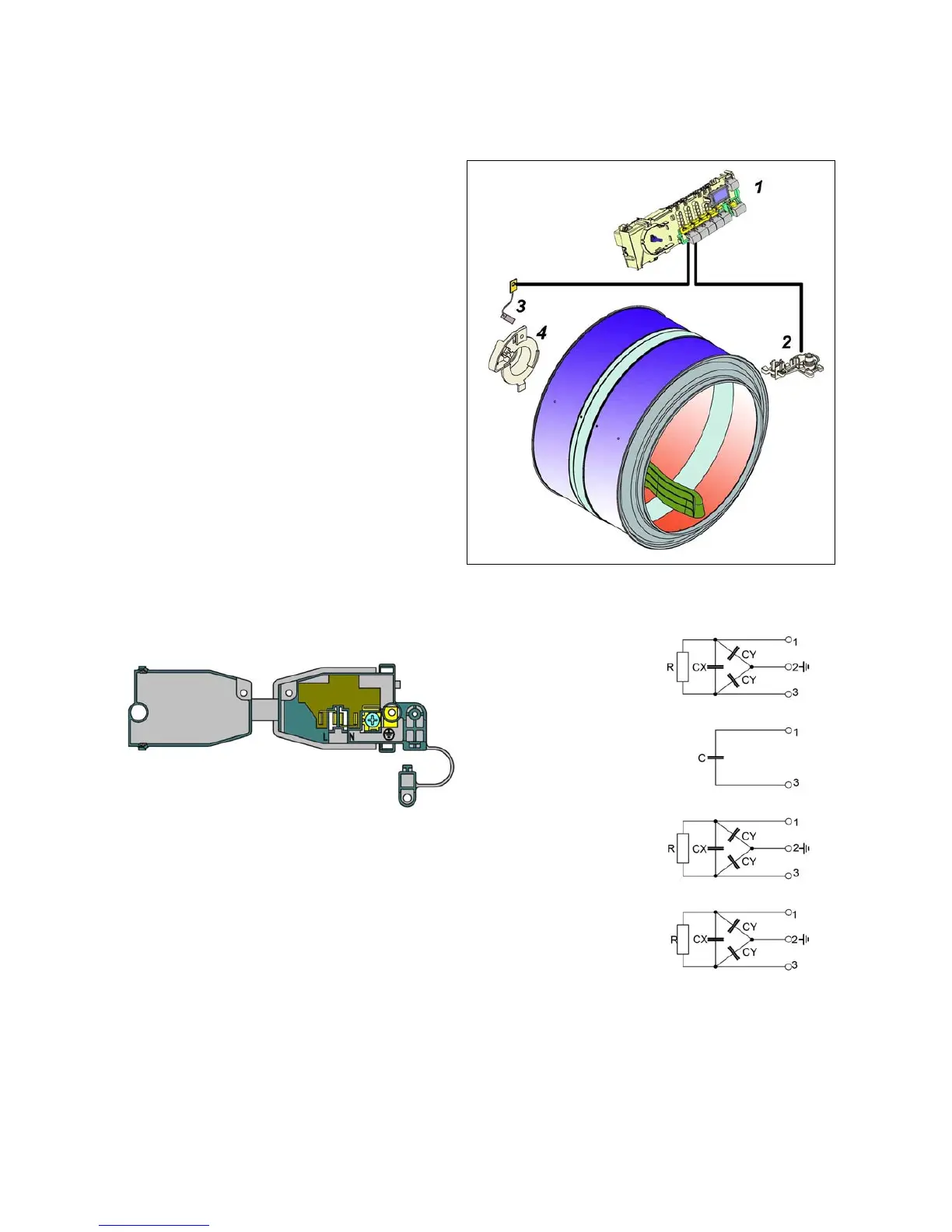

7.3 Junction box with integrated anti-disturbance filter

YELLOW label

CX = 0.25 µF

CY = 0.27 µF

R = 1 MΩ

FAWN label

C = 0.1 µF

CYAN label

CX = 0.25 µF

CY = 0.0047 µF

R = 1 MΩ

WHITE label

CX = 0.1 µF

CY = 0.0025 µF

R = 2.2 MΩ

The anti-disturbance filter (inserted into the junction box) has the job of preventing any radio disturbance

generated inside the tumble dryer from entering the power supply line.

This device only works correctly if connected to a proper earthing system.

Loading...

Loading...