Safety / Maintenance / Repair Works

BA_Elmasteam_8_Vers.07.2016 © Elma Schmidbauer GmbH

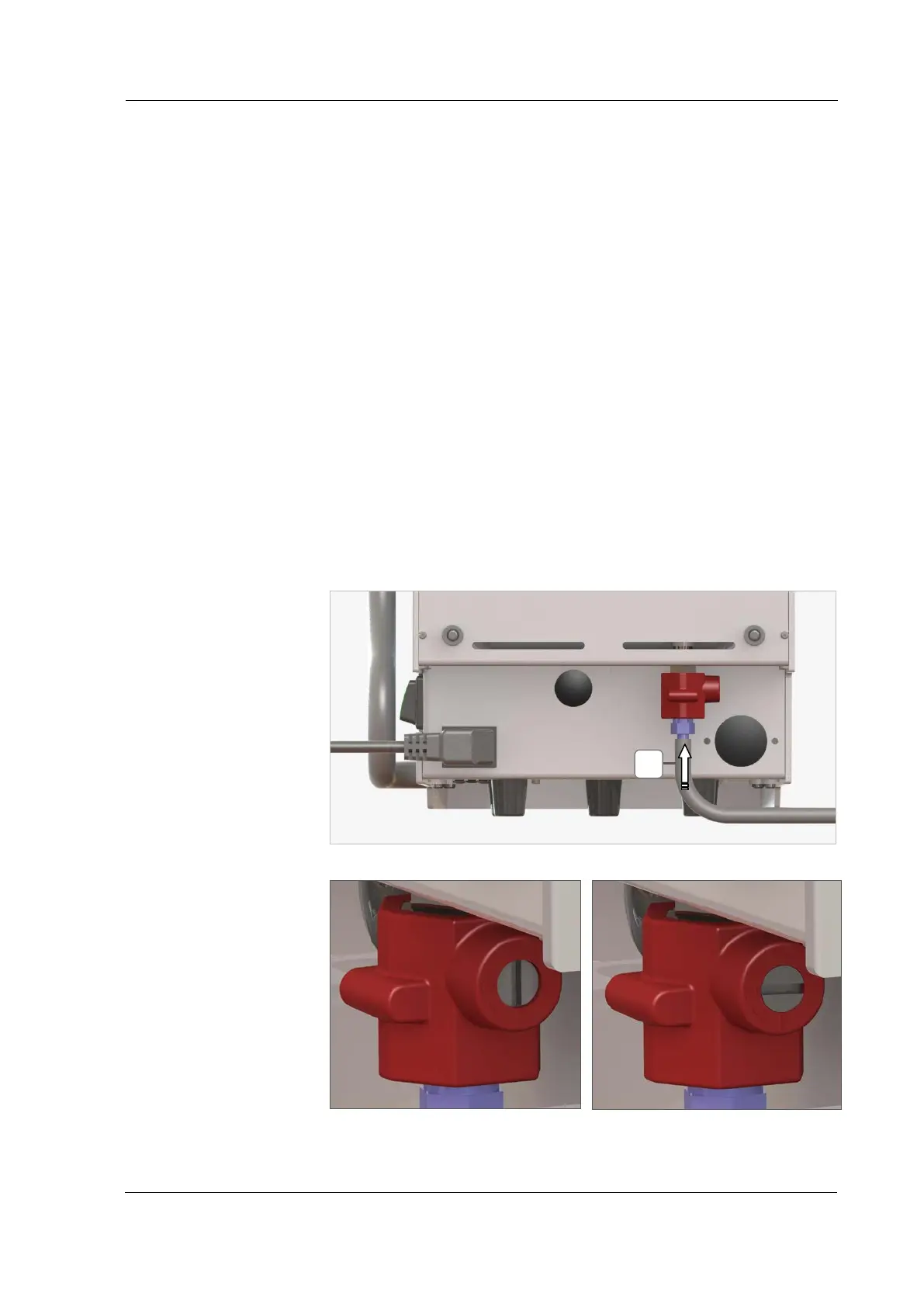

4. Open the ball valve with a screwdriver (Figure 8.2.2) and

initially drain off any residual water which may be in the

device.

5. Connect the flushing set to a water tap (3/4").

6. Utilise the hose from the flushing set to flush out the pressure

vessel in a circular motion.

This process must be continued until no more lime deposits

are purged from the pressure vessel.

The water is thereby able to quickly flow out of the pressure

vessel *.

7. Close the ball valve (Figure 8.2.3).

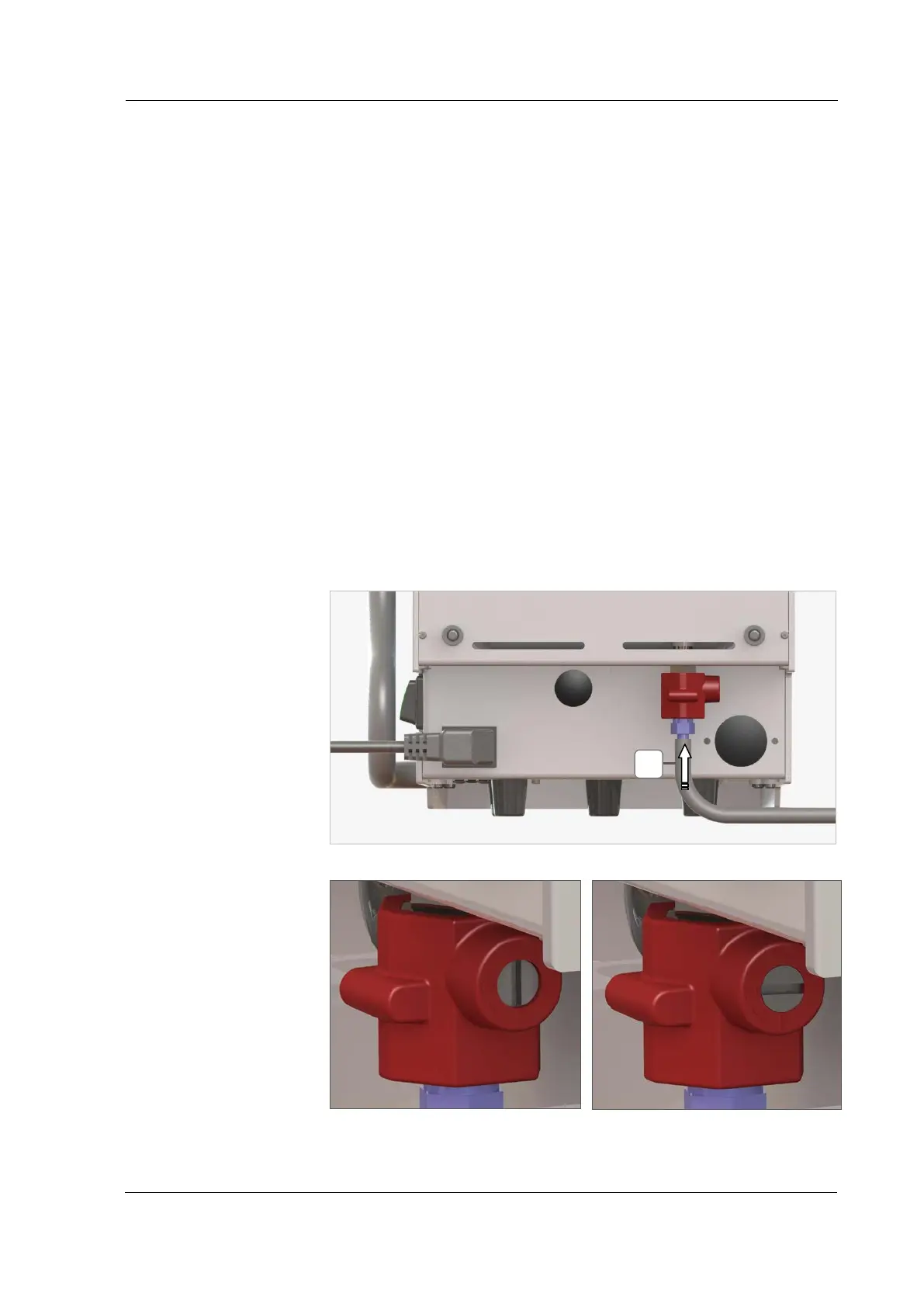

8. Remove the maintenance hose (Figure 8.2.1).

9. For devices that are operated in combination with a pump for

deionised water: Fill 1 levelled-off teaspoon of salt into the

pressure container after flushing (Chapter 6.2).

* If water does not flow out despite the ball valve being opened

then this normally indicates that there are lime scale blockages:

Remove the maintenance hose and free up the opening in the ball

valve with a thin object. Or flush out the ball valve with the flushing

set. Insert the flushing hose in the hose sleeving or directly in the

ball valve.

Figure 8.2.1: Connecting the maintenance hose to the ball valve

Figure 8.2.2: Ball valve Open

Figure 8.2.3: Ball valve Closed

Loading...

Loading...