Pos: 7.20 /0025 Üb erschriften/E LTRA 1.1 Übersc hriften/11 Gas s aving also f or resistance furnac e @ 9\mod _1425632688 373_9.docx @ 7 5312 @ 2 @ 1

5.10 Gas saving also for resistance furnace

Pos: 7.21 /0010 E LTRA/0015 s ervice_instructio ns/CS-2000_s ervice/15 Ser vice_CS-2000/15 55 Modul Gas s aving for resis tance furnace @ 9\mod_1425 543689791_9.d ocx @ 74826 @ @ 1

If this feature is required, the CS-2000 can be upgraded as follows. But the customer must take

care to have oxygen flow first before entering the sample into the furnace. The flow is restored

as soon as any button on the PC-keyboard is pressed. For example taking a sample weight.

If an organic sample is entered into the furnace without oxygen flow and the flow is

subsequently restored, it may lead to a very intensive ignition. Therefore, the gas saving feature

for the resistance furnace operation should only be installed after the customer’s consent to

take full responsibility for entering a sample into the furnace only after the flow is restored.

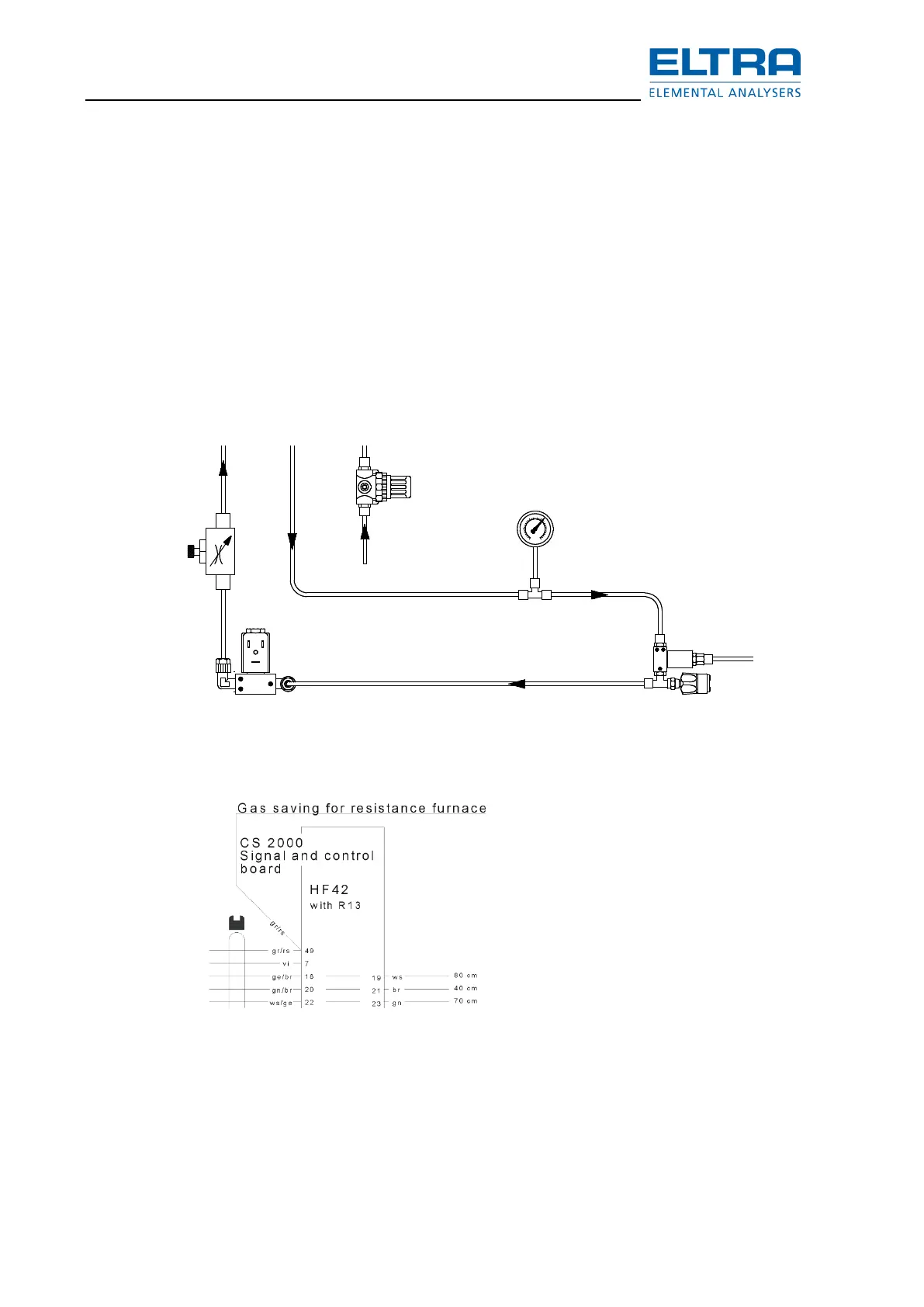

The modifications are shown in the following schematics. For full

Details, see chapter „Wiring diagrams“.

1. Install a solenoid valve No. 01160 in the analyzer’s cabinet.

: Gas saving for resistance furnace operation

2. Connect the valve in the tube leading to the resistance furnace inlet (close one port of the

T-piece of the valve, like already done for V3).

: Gas saving for resistance furnace operation

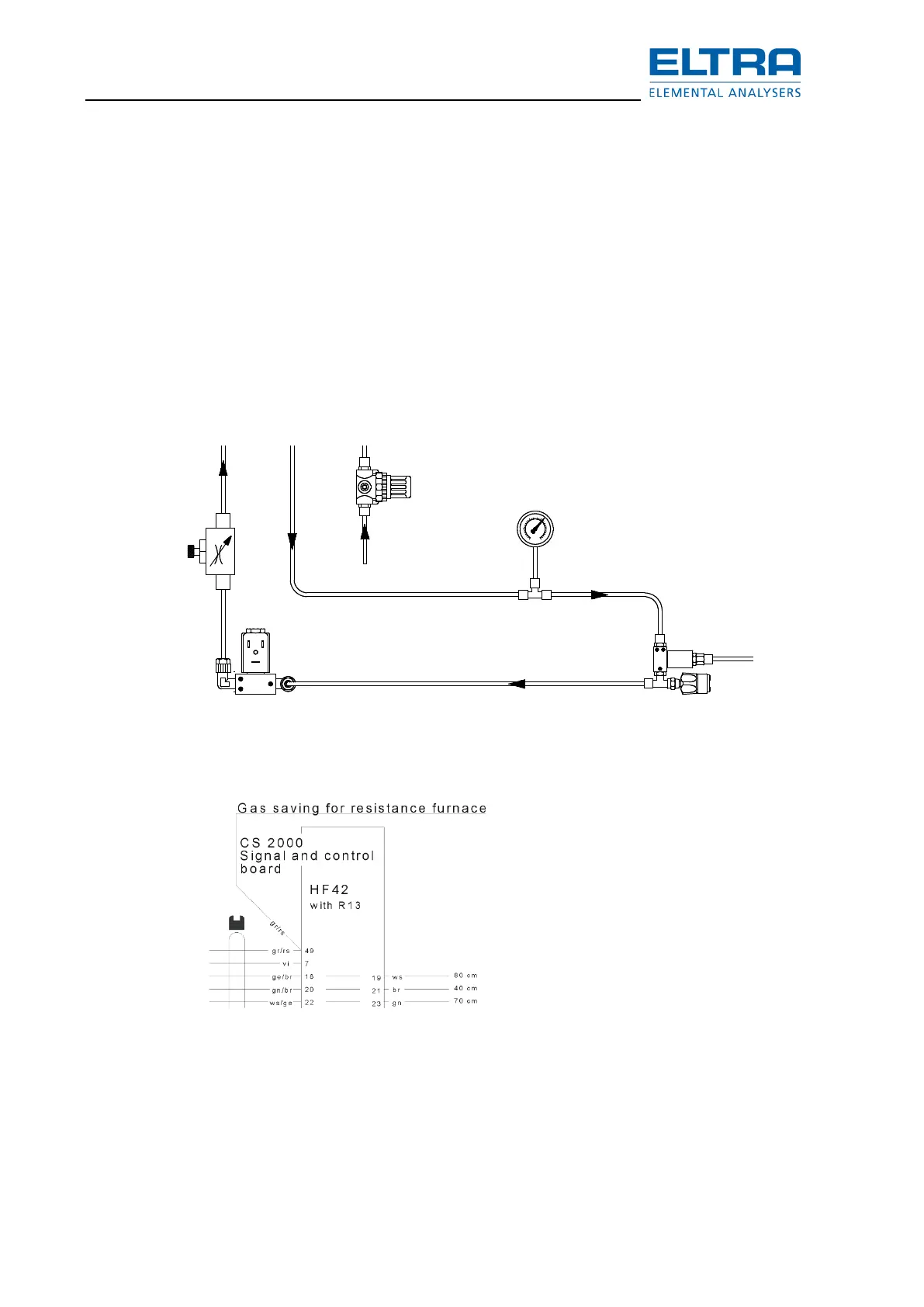

3. Connect a cable to pin 49 of the 50-pin plug to the board HF-42.

Loading...

Loading...