3.10.1 Induction furnace operation

- No oxygen pressure. See corresponding chapter “No oxygen pressure”

- The software is in the gas saving mode. If this is the case, the flow will be restored when

the mouse is moved or when a key is pressed like F4 for entering the sample weight or

F2 for opening and closing the furnace.

- Bent plastic tube. See chapter “Fluctuating gas flow”

- Faulty flow sensor, flow control board or valve. See chapter “Gas flow controller”

- The tubes of the flow sensor are interchanged (input <--¬¬> output).

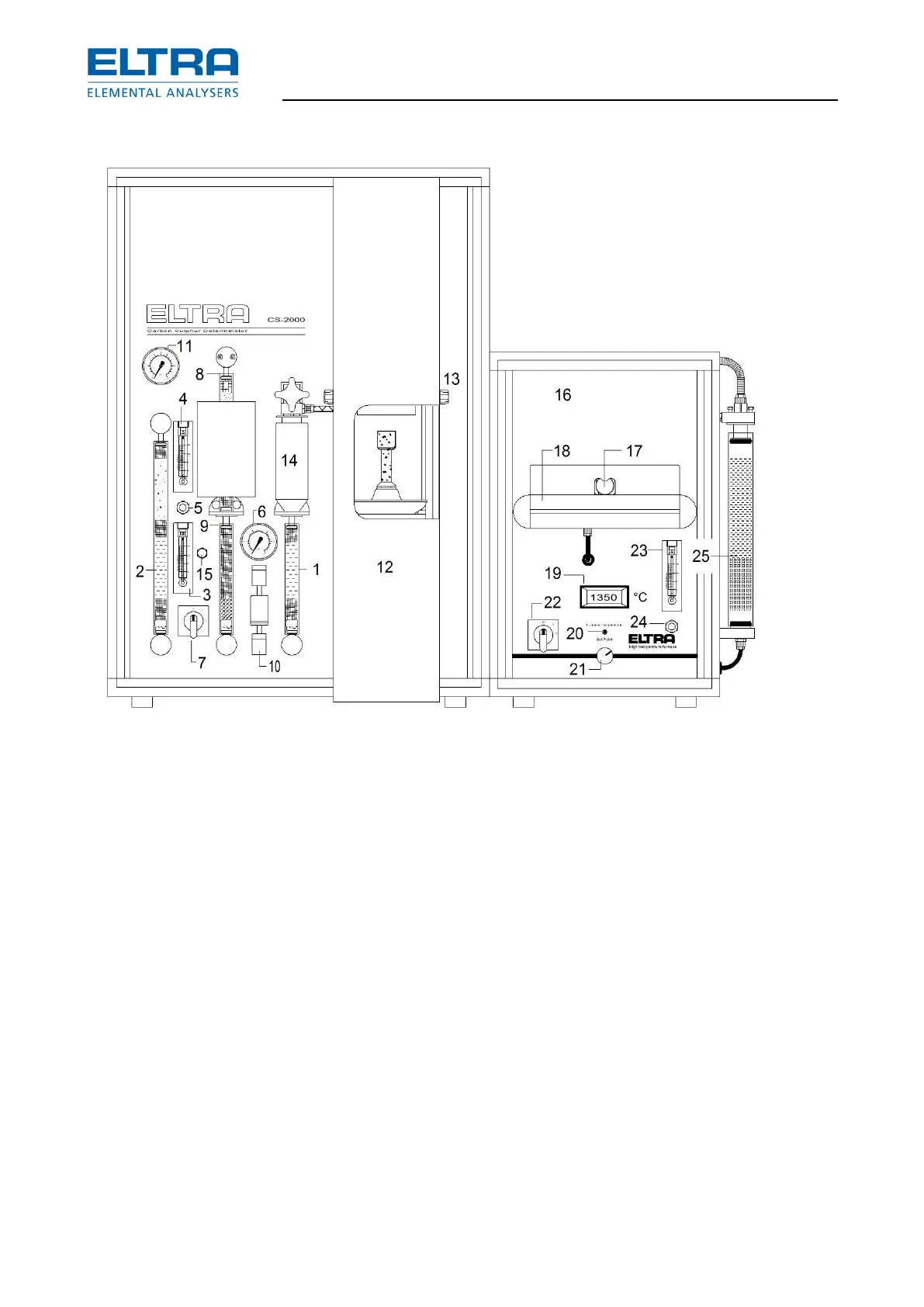

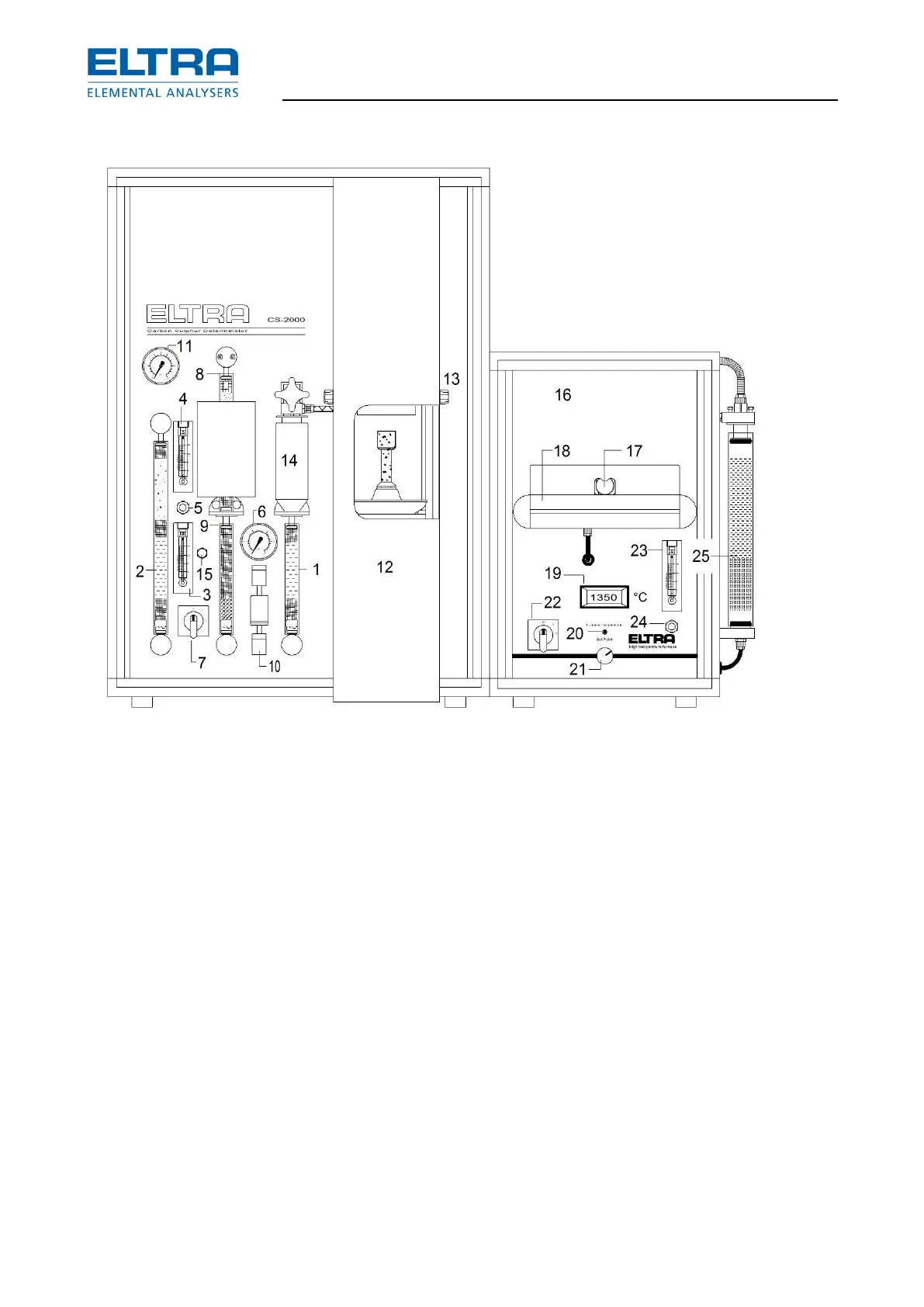

See chapter “Gas flow diagrams”

– The outflow valve V1 does not close. Open the left-side panel of the analyzer. When the

furnace is closed (the lift is up), no oxygen should be flowing out of the lower (free)

opening of the valve. See chapter “Gas flow diagrams”. This can be checked by putting

your finger under the lower opening of the valve. If the valve does not close correctly, you

will feel a strong oxygen pressure. The voltage across the leads of the outflow valve V1

should be 0 Volt. If this is the case then the plunger of this valve jams. The valve should

be cleaned (see chapter “Cleaning the solenoid valves”) or be replaced. If the voltage

on the outflow valve is permanently at 24 V, switch off the analyzer, exit the software and

restart.

Loading...

Loading...