Check by removing the filter with the dust filter housing. See chapter: “High carbon results are

erratic”.

Don’t remove the filter from its housing.

Turn the filter housing upside down and try to blow air through the smaller whole (about 16mm

diameter) of the filter housing.

If you feel a remarkable restriction, replace the filter by a new one. With a new filter the air

should pass practically free without any restriction.

Blocked chemicals:

The grains of magnesium perchlorate as well as of sodium hydroxide have to move when

knocking on their glass tube. If they are cloggy, they are completely depleted and they have to

be replaced. When the glass tube is turned upside down, the grains should fall off. If a screw

driver is needed to stab the grains free, the chemicals had to be replaced much earlier.

Blocked paper filters:

The paper filters are small so that they are frequently forgotten or neglected, although they can

block the flow when they are not replaced for long.

Blocked lance hole over the crucible:

The hole in the ceramic heat shield over the crucible in the induction furnace can be restricted

or blocked.

Clean by using the brass brush as described in the operation manual. If this may not be enough

then clean the hole by using a piece of wire or a pipe cleaner.

Blocked furnace outlet:

For induction furnace, unscrew the cap-nut at the furnace outlet and remove the plastic tube.

Pass through the fitting a pipe cleaner. Open the furnace in order to be sure that the pipe

cleaner has passed thru the fitting reaching the furnace area.

Completely remove the plastic tube by unscrewing the left hand cap-nut on the dust filter

assembly. Clean this fitting the same way like before. If necessary clean the plastic tube as well.

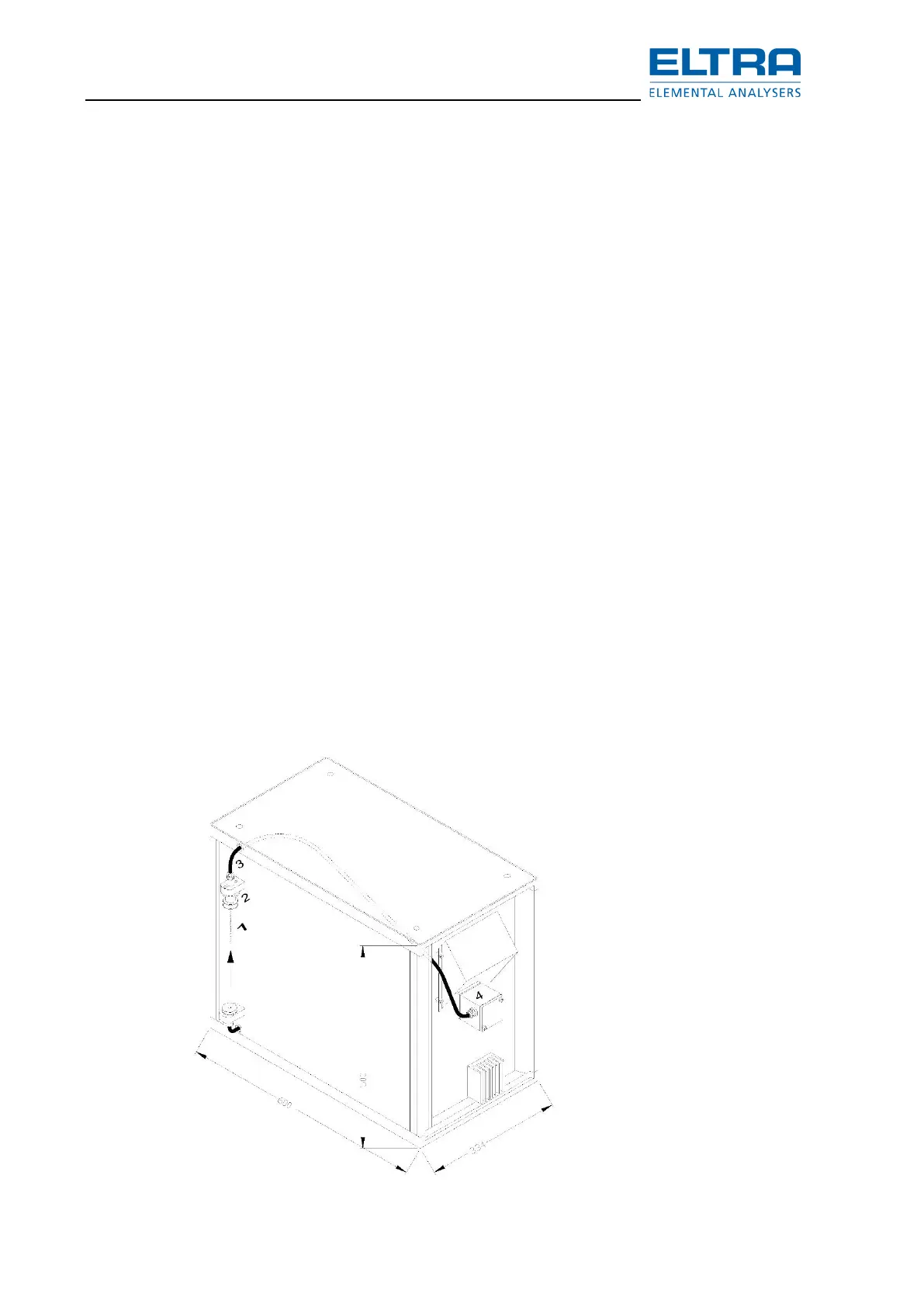

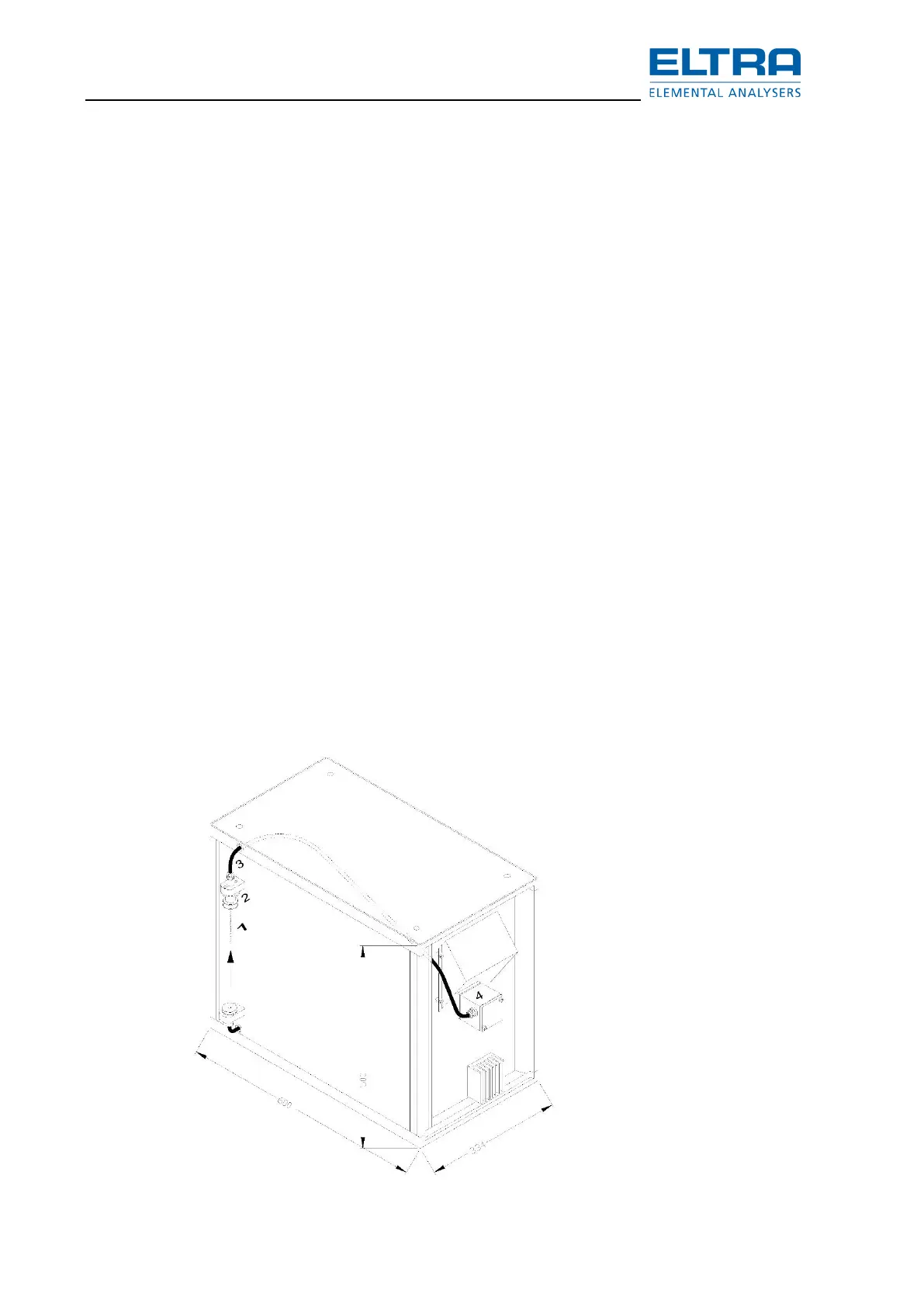

In case of resistance furnace operation clean the furnace outlet as shown below.

Loading...

Loading...