After starting an analysis”, the following message appears: "no oxygen pressure".

If this message permanently remains in the “status window”, then check

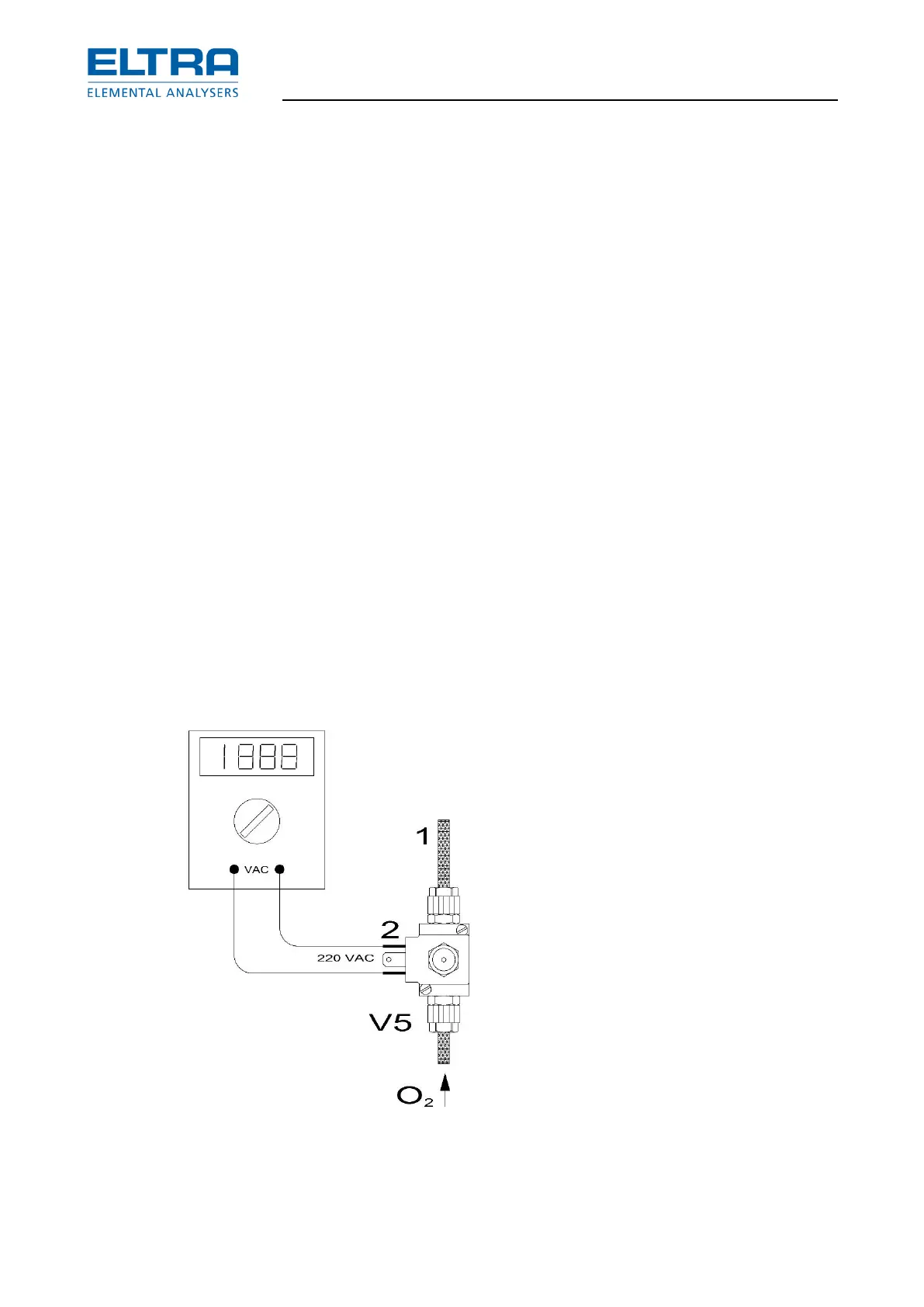

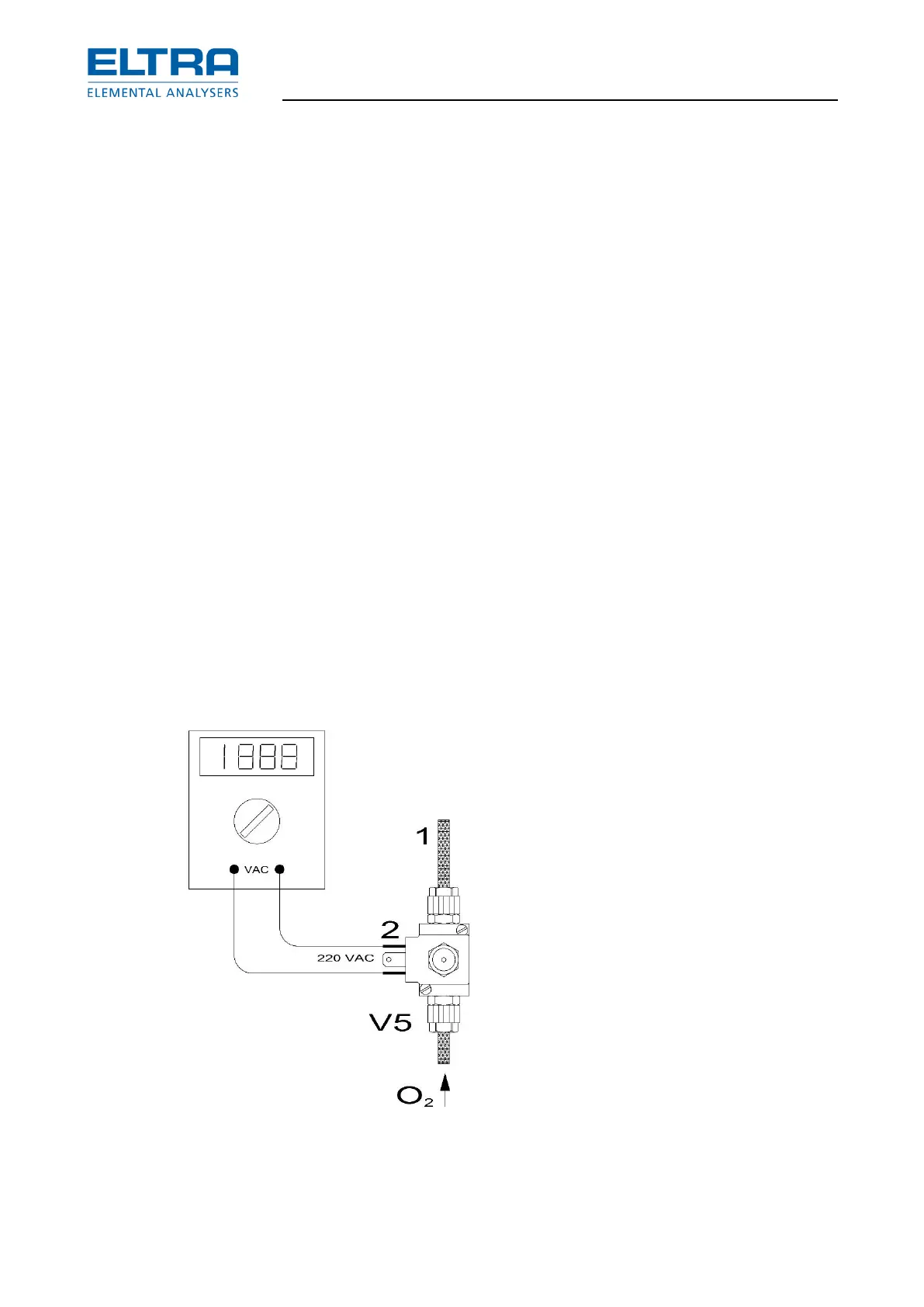

– Is the power switch (1) set on position 3?

– The pressure on the oxygen gauge (2) may be too low. 1.5bar is normal (22psi). The

pressure remains constant when the furnace is closed, and it sinks during the upward

movement of the furnace floor.

– Check the oxygen pressure in the supply line or tank. 4 to 6 bar (60 to 90psi)

showing on the pressure gauge is normal.

– Check if the pressure gauge for compressed air (5) shows 4 to 6 bar (60 to 90 psi).

– Check if the cock (3) is properly shut, or else the O-ring (4) will not seal Check if the

O-ring (4) is in a good condition.

– Check if the combustion tube is broken or cracked.

– Do leakage check. See chapter: “Leak checking”.

– Check if the chemicals are saturated and have become hard.

– The paper filter could also be the cause. For changing the paper filter, read the

operating manual.

– See chapter “Fluctuating gas flow”

– The contents of the gas cleaning furnace could be worn out and clogged.

Oxygen solenoid valve (V5) may be defective:

– Open the left-side panel of the analyzer.

– Unscrew the upper tube (1). The oxygen should rush out when the power switch is set

to pos. 3

If not:

– There may be no oxygen supplied.

Loading...

Loading...