CAUTION Switch off the mains power when handling inside the analyzer.

If a tube fitting is blocked, then the tube may be blocked as well.

Therefore the tube needs to be cleaned or replaced, otherwise the contamination could reach

the IR-cell as well.

2. The IR-cell is blocked

This fault is caused mainly by a kink in one of the tubes.

A blockage due to contamination may appear in one of the fittings of the IR paths, where

is a minimum diameter in the gas flow, compared to the inner diameter of the tubes.

3. Leakage

Not only blockages of the flow can cause the pump to run with full power, but also

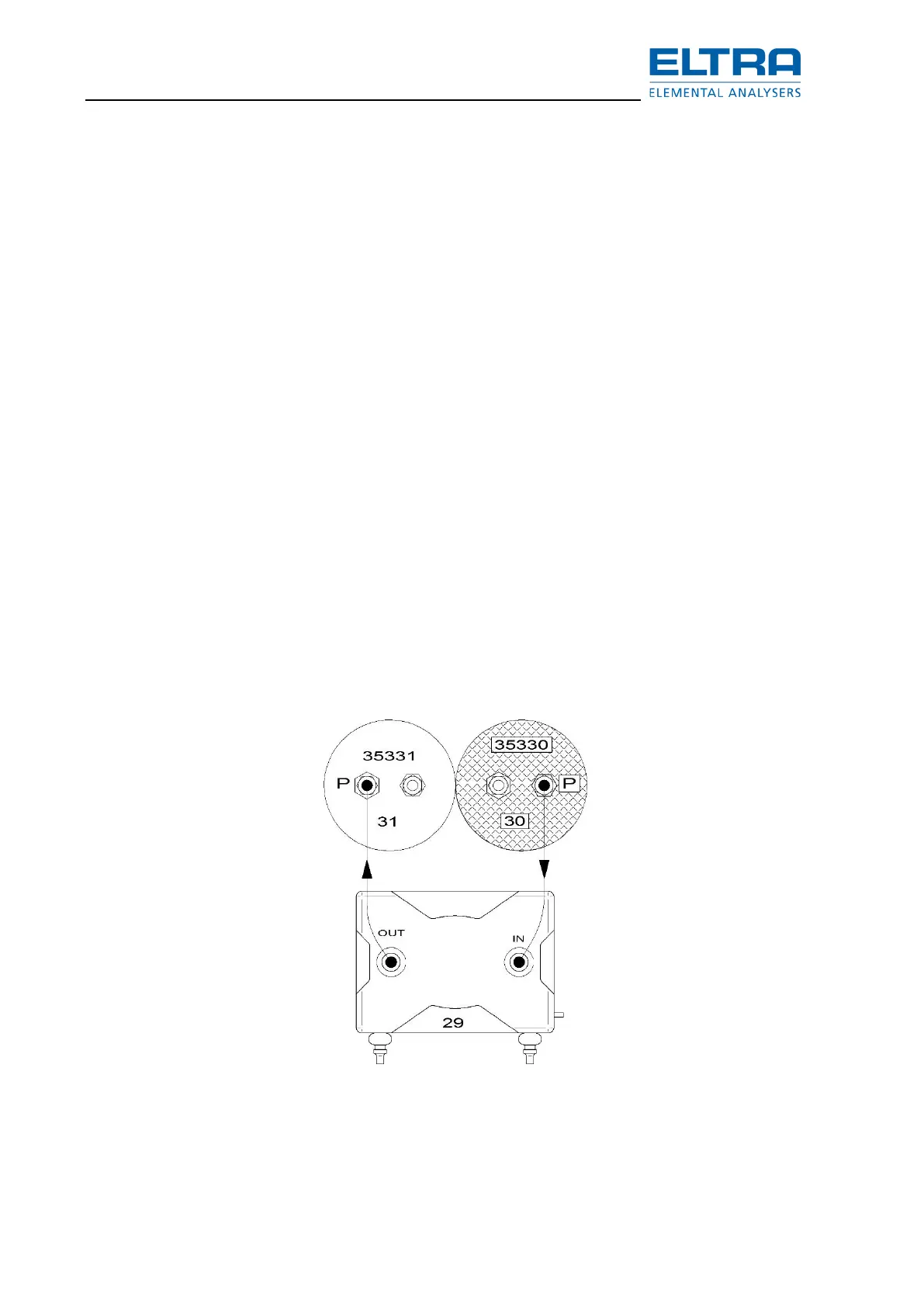

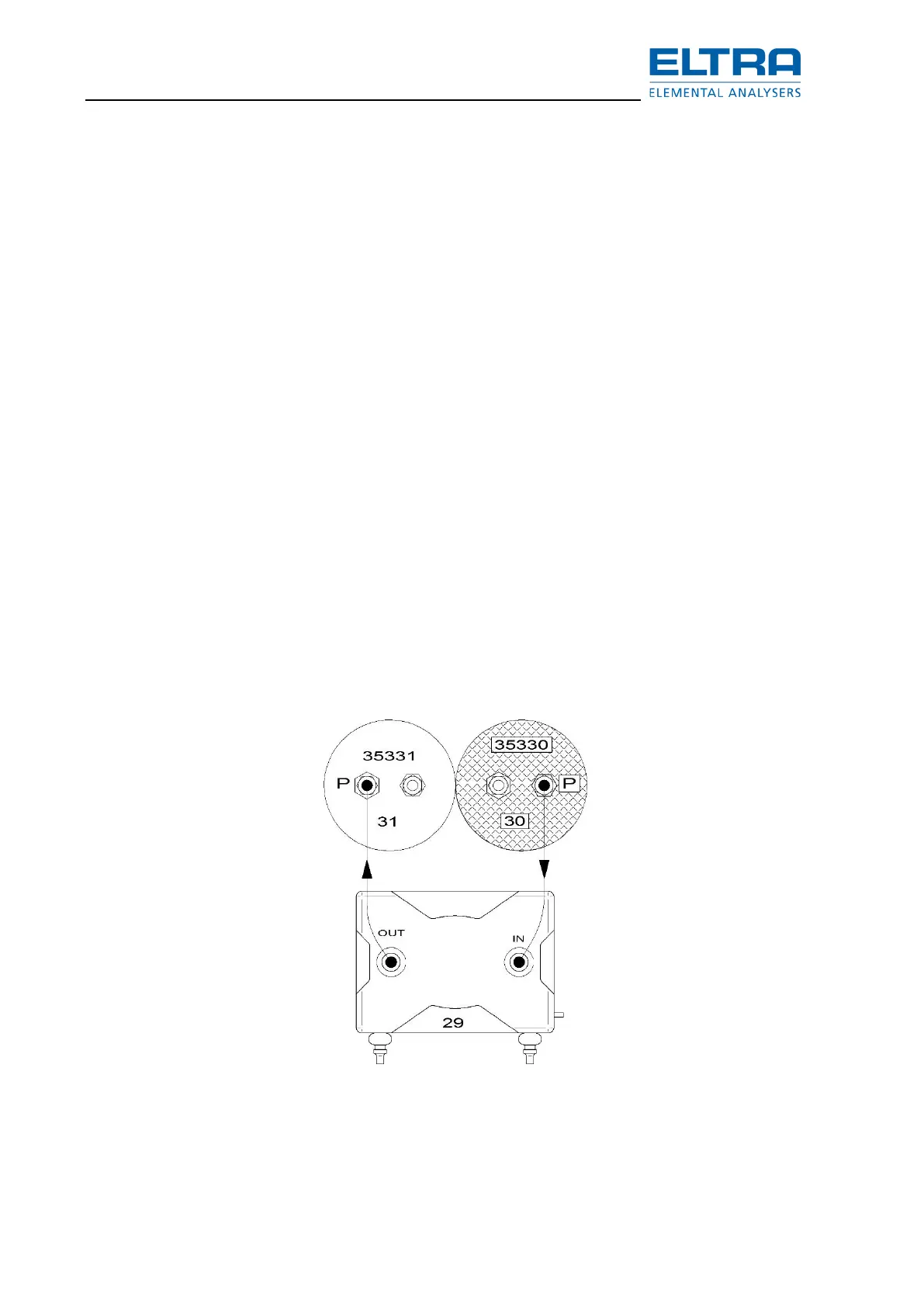

leakages between the flow sensor (37) and the pump (29) can cause the pump to run at

maximum power.

Occasionally, the cover of the attenuator (30) (see also below) is not properly sealed, or

the gas flow meter (20) has a crack at the fittings for the tube connections. Disconnect

the gas flow gauge and check for cracks.

4. Blockage in the lower connection of the thick glass tube (22)

If there is not enough quartz wool used underneath the magnesium perchlorate, fine

particles fall down to the glass fitting causing blockage in its hole.

– Remove the glass tube (22). See operation manual “Filling the reagent tubes”.

– Remove the tube from the lower fitting.

– Clean the hole by passing a wire or a pipe cleaner.

5. Cotton wool is dirty

Another possibility could be that the cotton wool inside the glass (30) is very dirty.

CAUTION Don’t interchange the tubes of the glasses

Loading...

Loading...