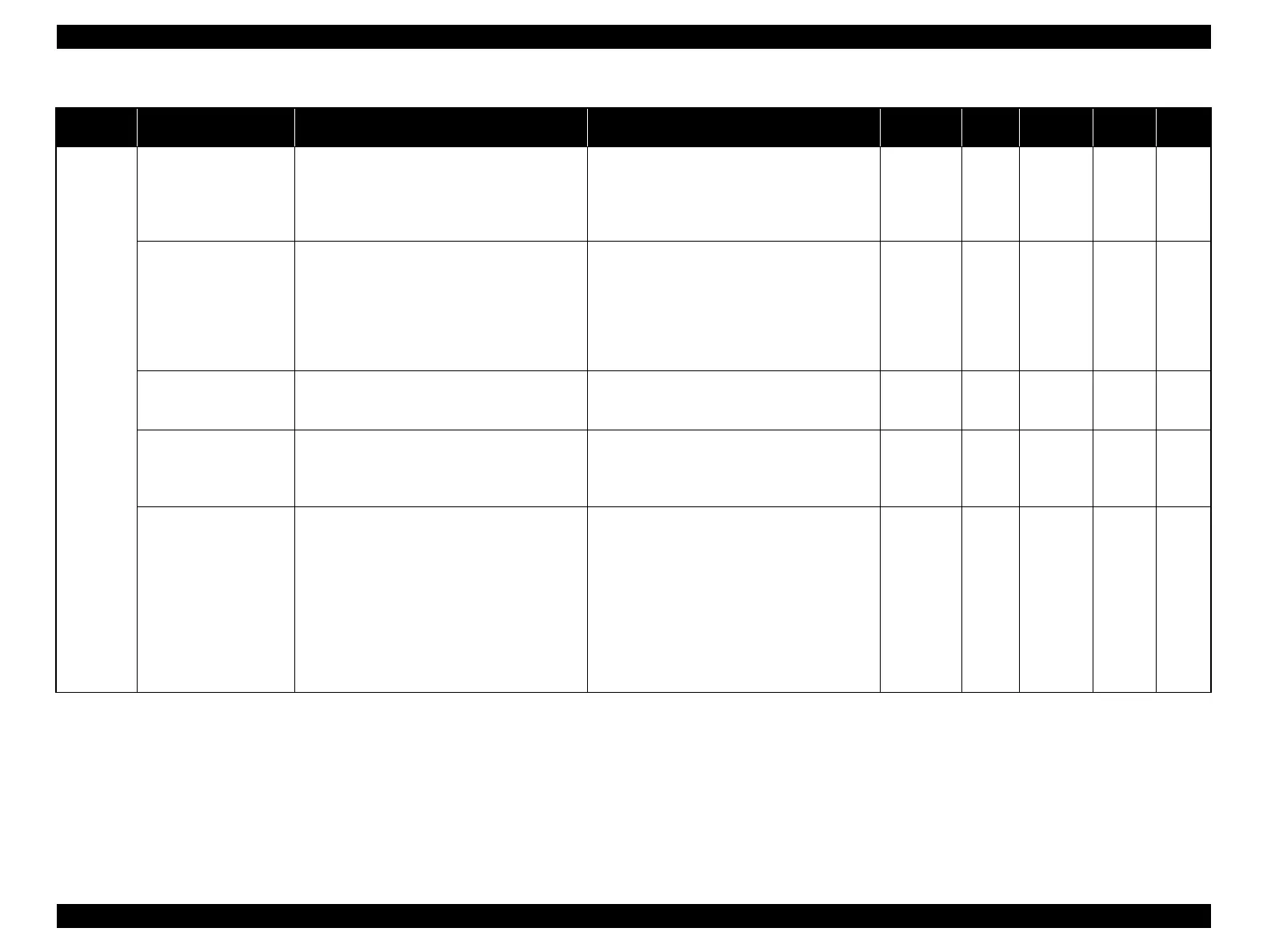

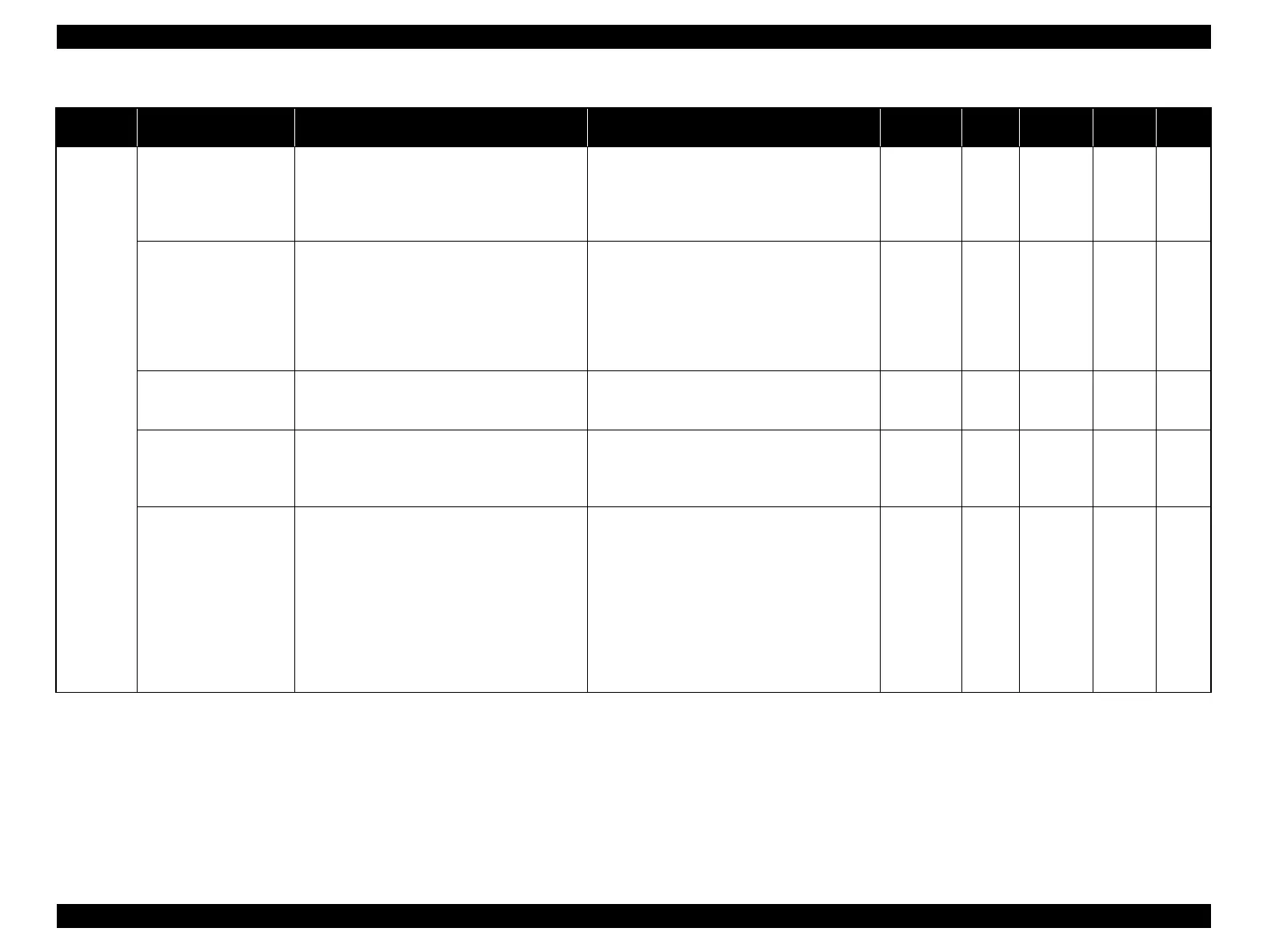

SC-F9200 Series Revision C

ADJUSTMENT Overview 275

SE Group Confidential (Related Staff Only)

Head

related

Head inclination manual

adjustment

(CR direction)

Correct inclination of the Print Head in the CR

direction. Print an adjustment pattern, and

visually check the pattern to see if the adjustment

is needed. To correct the head inclination, turn

the cam.

If this adjustment is not made, print quality

problems such as misaligned lines, grainy image,

banding, or color unevenness may occur in the

scale of Print Head surface area.

Normal

mode

√

PGPP

p.314

Head slant auto

adjustment

(PF direction)

Correct slant of the Print Head in the PF

direction. An adjustment pattern is printed and

the IM Sensor scans the pattern. Based on the

scanned result, a number of steps to move the

lever for the adjustment is displayed. Move the

lever the number of steps to correct the head

slant.

If this adjustment is not made, the gap between

the Print Head surface and paper is kept uneven

(e.g.: the gap at the front side is wider than that at

the rear side), and causes irregularity in size and

position of printed dots. This may be observed as

print quality problems such as grainy image,

banding, or color unevenness.

Normal

mode

√

PGPP p.319

Manual Adjustment for

Data Shift

To make the setting not to use the Head 2 nozzles

that overlap with the Head 1 nozzles in the sub-

scanning direction.

---

Normal

mode

√

PGPP p.321

Manual Uni-d

Adjustment for Between

2pcs heads

Correct the variation of the landing positions

between the Head1 and Head2 in the CR

scanning direction.

If the variation is not corrected, misaligned

landing positions may cause print quality

problems such as misaligned lines, grainy

images, or banding.

Normal

mode

√

PGPP p.323

Ink Mark Sensor check &

Auto Adjustment

Check if the Ink Mark Sensor has any trouble/

connection failure.

Execute IMS Position Auto Correction

(pattern detecting position correction).

Correct the detecting position of the print

pattern in the sub scan direction and the main

scan direction.

Run the nozzle check and to confirm whether

the Ink Mark Sensor detects the nozzle

clogging properly.

If the IMS does not work properly, automatic

adjustments such as Manual Bi-D Adjustment

cannot be executed normally.

Normal

mode

√

PGPP p.303

Table 4-2. Adjustment Items

Class Adjustment Items Overview Symptoms that the Adjustment is Needed Printer Mode

Service

Program

Jig Media Page

Loading...

Loading...