SC-F9200 Series Revision C

TROUBLE SHOOTING Trouble on Paper Feeding 68

SE Group Confidential (Related Staff Only)

2.5 Trouble on Paper Feeding

This section describes the possible troubles on paper feeding and their causes and remedies.

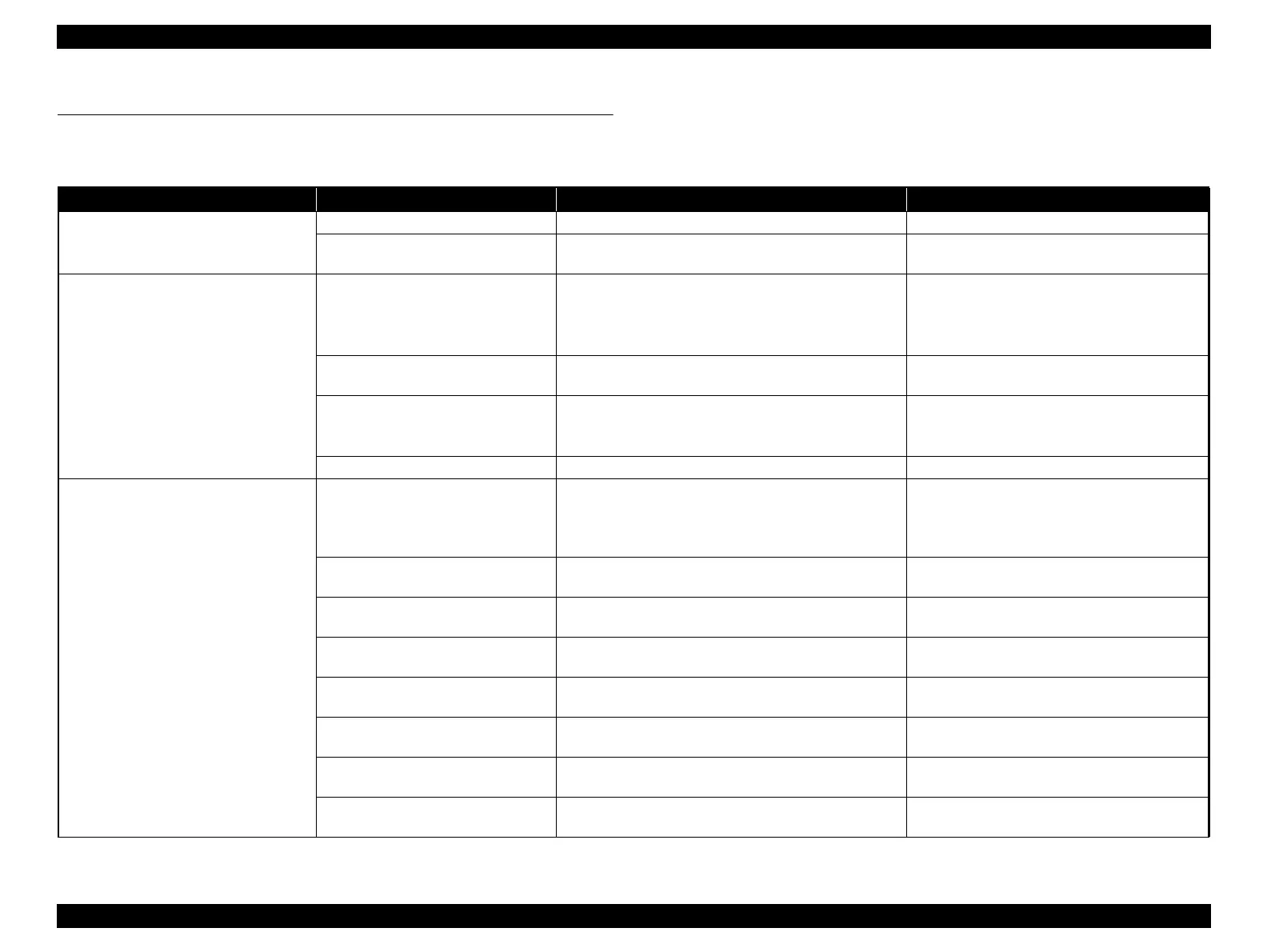

Table 2-6. Trouble on Paper Feeding

Symptom Cause Check Item Remedy

Paper is not fed into the printer properly.

Improper PE Sensor adjustment

---

Perform the Rear AD Adjustment. (Page 358)

PE Sensor failure

Does the PE Sensor work normally? Check it using the

Service Program.

Replace the PE Sensor. (Page 224)

Paper feeding or paper ejecting is

abnormal.

PF Scale or PF Encoder failure

1. Is the PF Scale damaged or contaminated?

2. Is the PF Scale attached properly?

3. Is the PF Encoder installed correctly?

1. Clean the PF Scale.

2. Reinstall the PF Scale and PF Encoder.

3. Replace the PF Scale

(Page 216) and PF

Encoder (Page 215).

The tension of the PF Timing Belt is not

proper.

---

Correct the tension of the PF Timing Belt. (Page

338)

Suction setting failure

Suction fan failure

1. Is the suction setting proper?

2. Does the Suction fan work normally? Check it using the

Service Program.

1. Make the suction setting properly.

2. Replace the Suction fan.

PF rollers failure Are the PF rollers contaminated or damaged? Clean the rollers or replace them.

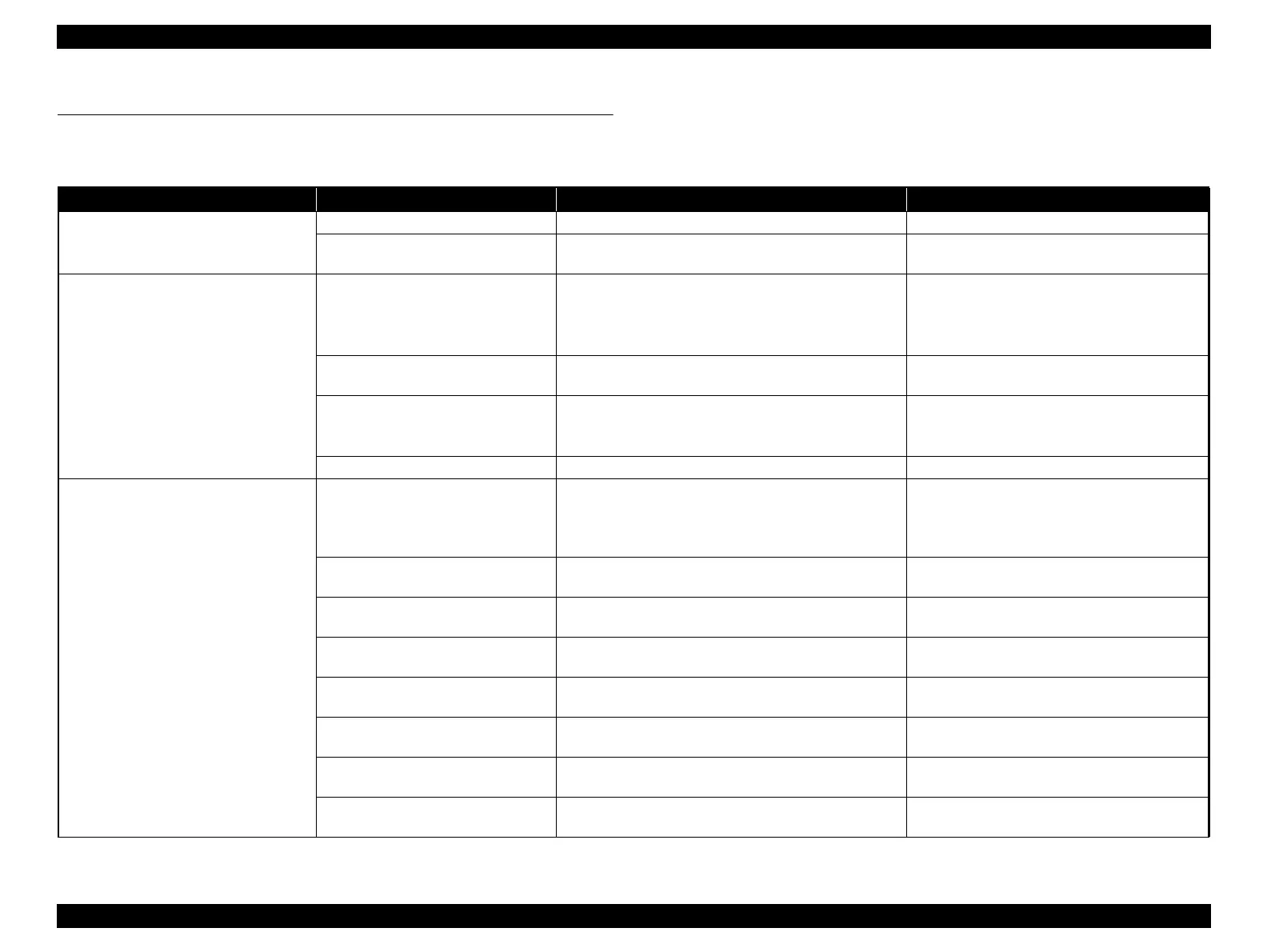

Paper is skewing.

The Roll Unit or Reel Unit is not

parallel.

---

1. Perform the parallelism adjustment of the Roll

Unit or Reel Unit referring the Set Up Guide.

2. If not improved, perform the After Heater

Positioning Check.

(Page 360)

The Paper Skew Check function has

been disabled.

---

Enable (select “ON”) the Paper Skew Check

function.

The Paper Size Check function has

been disabled.

---

Enable (select “ON”) the Media Size Check

function.

The PW Sensor is not working.

Does the PW Sensor work normally? Check it using the

Service Program.

Replace the PW Sensor.

(Page 204)

The Roll Unit parallelism adjustment

has not been made.

---

Carry out the Roll Unit parallelism adjustment.

The Reel Unit parallelism adjustment

has not been made.

---

Carry out the Reel Unit parallelism adjustment.

Roll paper edge is attached to the take-

up reel at an angle.

---

Attach the paper to the take-up reel correctly.

The paper holddown plate is pressing

paper too strong.

---

Align the holes on the plate with the edges of

paper.

Loading...

Loading...