EPSON Stylus CX3100/3200 Revision A

Troubleshooting Troubleshooting for Printer 24

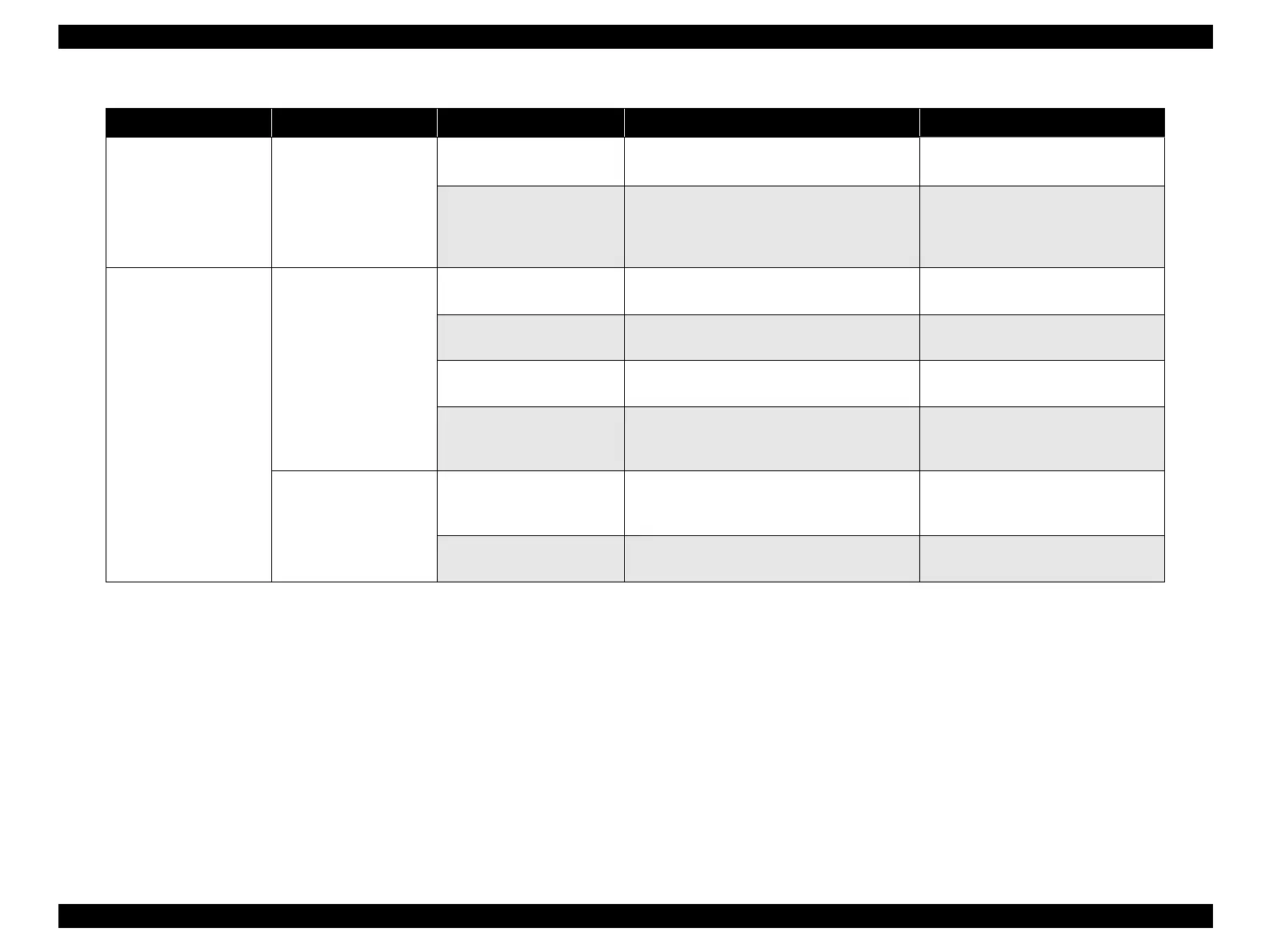

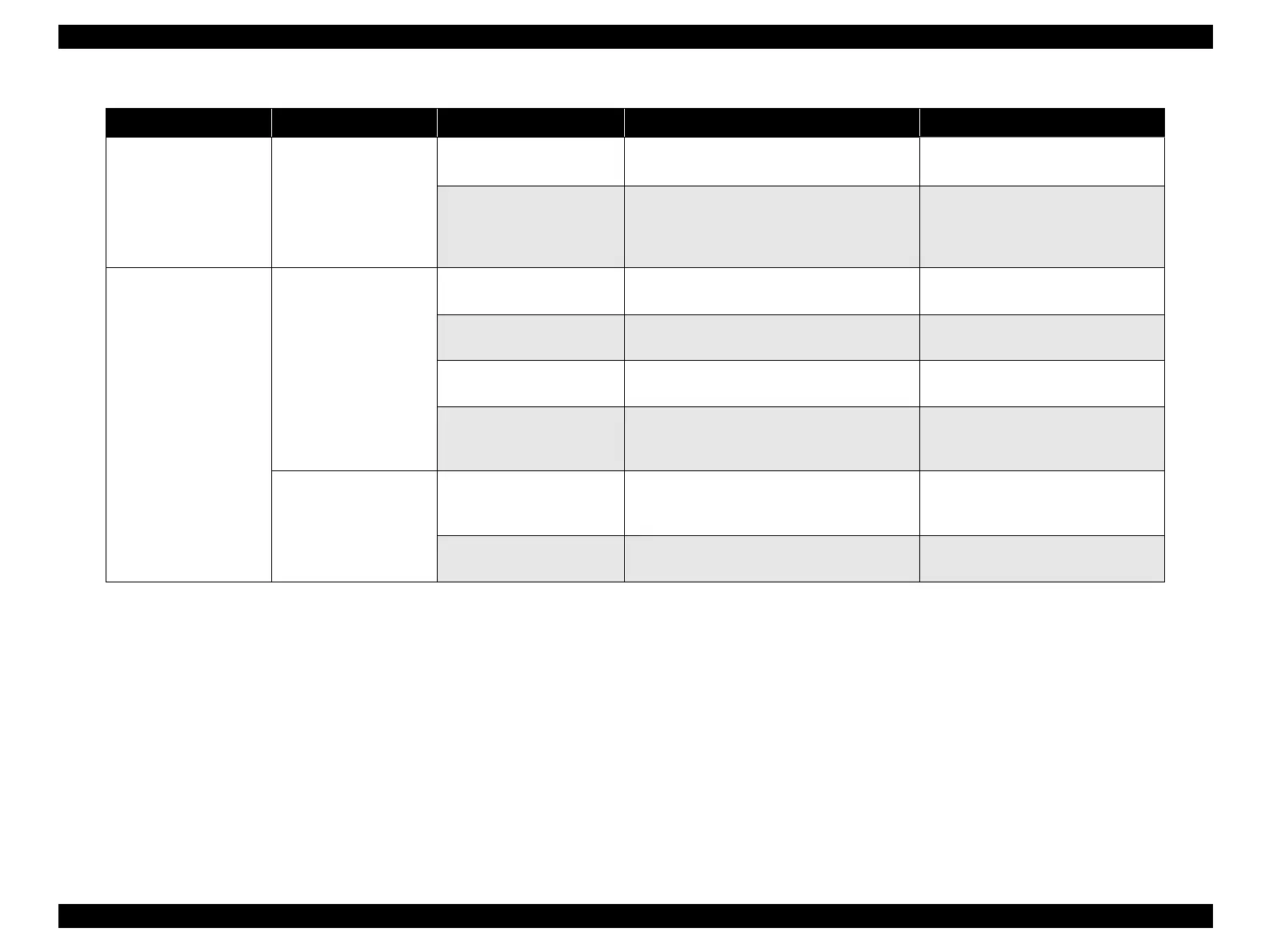

Table 3-4. Printer Mechanism Repair

Observation Condition Cause Check Point Remedy

Faulty pump mechanism When power is turned on,

PF motor operation is

abnormal.

There are foreign matters on

the PF gear.

Operate the platen drive gear by hand and check

whether it rotates properly.

Remove foreign matters.

Replace the printer mechanism.

PF motor is faulty. Check whether the internal coil resistance is just

as specified and whether the harness is connected

properly. See Table 3-13, “Motor Resistance and

Check Point,” on page 33.

Replace the printer mechanism or PF

motor.

Ink is not absorbed at all

or ink absorption is poor.

Ejected ink does not flow

into Ink Eject tube.

Pump tube is crashed. Check tube with the naked eye. Replace the printer mechanism or pump

unit.

Capping unit is faulty. Check capping rubber with the naked eye. Replace the printer mechanism or

capping unit.

Tube is projecting from cap. Check with the naked eye whether tube is

projecting from cap.

Connect the tube correctly.

Pump tube is entangled in the

pump unit.

When cap assembly slides up completely, check

whether there is a small slack in pump tube

between cap assembly and pump unit.

Remove the entangled pump tube

carefully, correct the tube condition and

connect it to the cap assembly.

Ink is not absorbed from

head to cap.

Dirt on cap Check whether any foreign matter is adhering to

cap.

Remove foreign matters from the cap

and if the cap is damaged, replace it

with a new one.

Faulty slide-up of cap Check whether two compression springs are set

on cap assembly.

Set the compression springs on the cap

assembly.

Loading...

Loading...