EPSON Stylus Photo R1900/R2880/R2000/R2000s/SC-P400 Series Revision I

Adjustment Adjustment 148

5.2.2.1 PG Adjustment Method

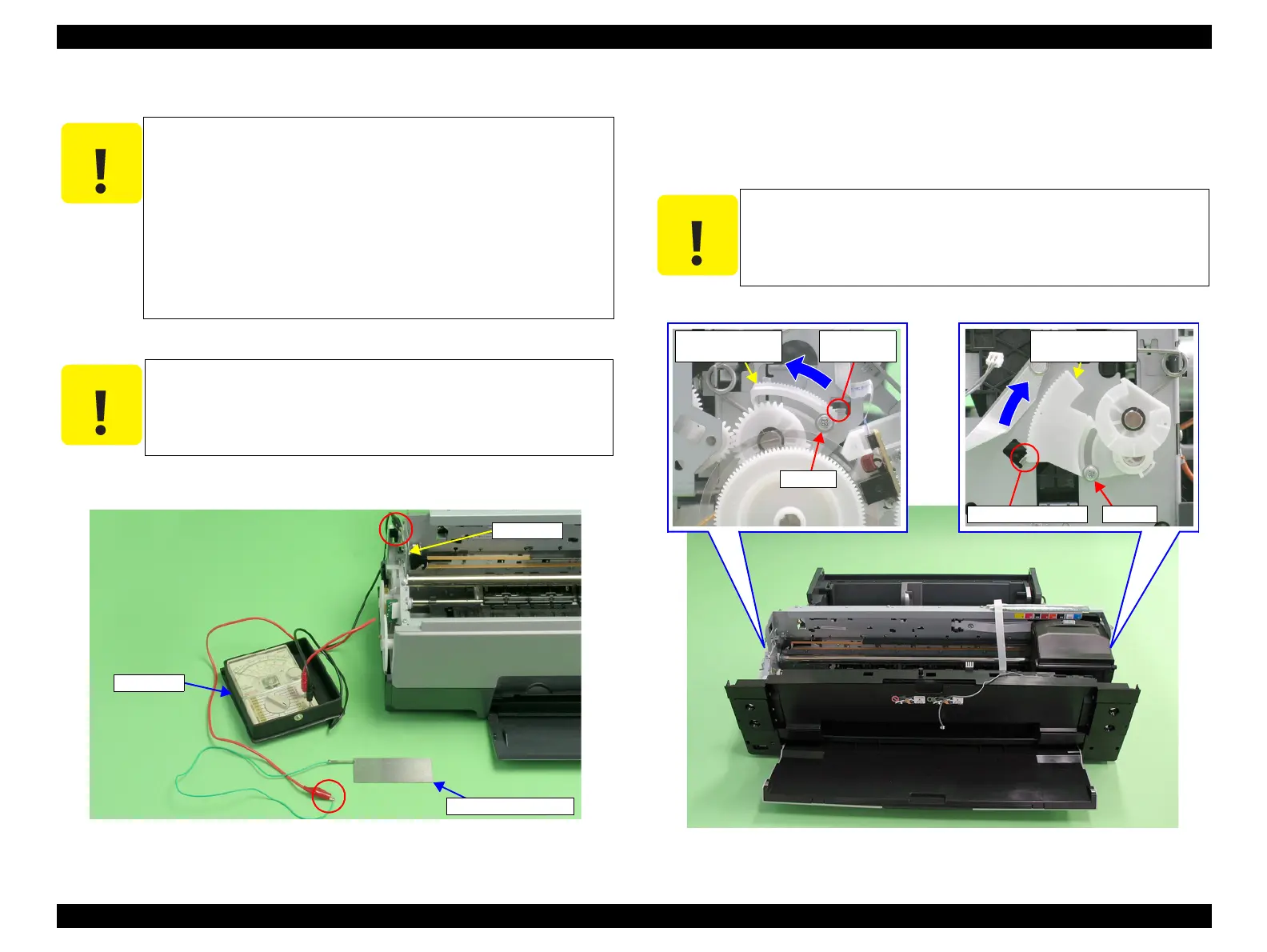

1. Install the printer on a level base.

2. Connect the Tester to the printer frame and Adjustment Gauge.

Figure 5-4. Connecting the Tester

3. Load unused Ink Cartridges of all colors into the Carriage Unit.

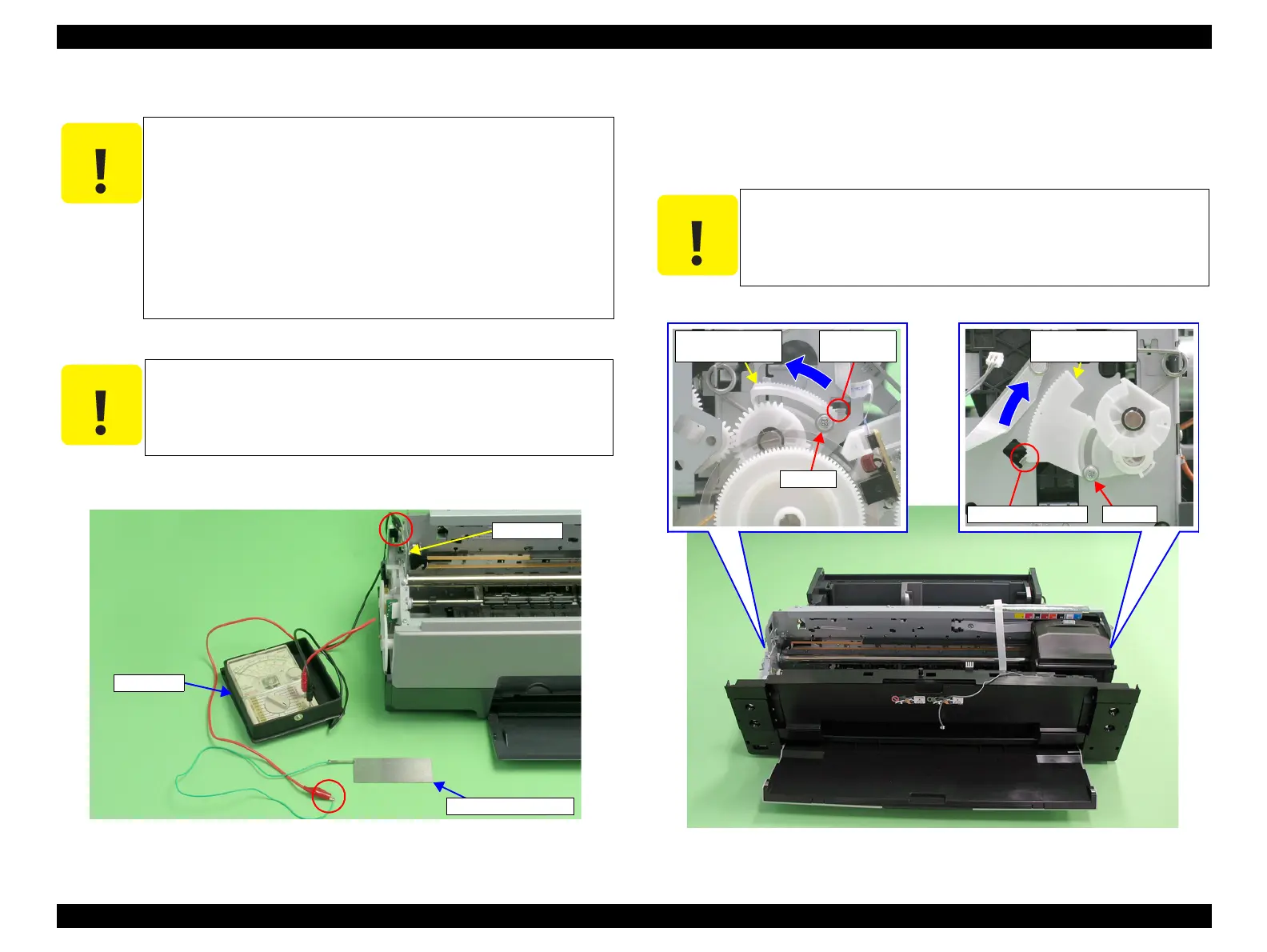

4. Loosen the screw that secures the Parallelism Adjust Bushing.

5. Turn the Parallelism Adjust Bushing upward to match the frame edge and the

bottom of the Parallelism Adjust Bushing gear.

Figure 5-5. Setting the Parallelism Adjust Bushing

Before starting PG adjustment, completely wipe drops of ink

around the Print Head. Remaining drops of ink will stick to the

continuity measurement portion of the Adjustment Gauge, and

generate continuity before the continuity measurement portion

makes contact with the metal frame around the Print Head,

interrupting accurate PG Adjustment.

As the ink in the Print Head may stick fast and damage the

Print Head during PG Adjustment, make the continuity time

detected with a tester as short as possible. (Maximum 3

minutes)

Place the printer on a level, warp-free table. Normal PG

Adjustment cannot be performed on a warped table.

Frame

Tester

Adjustment Gauge

When the Parallelism Adjust Bushing is turned upwards, the frame

rises up and PG narrows. Make sure that the frame does not come

into contact with the Print Head when performing the following

procedure.

Parallelism Adjust

Bushing

Positioning Point

Screw

Positioning

Point

Screw

Parallelism Adjust

Bushing

Loading...

Loading...