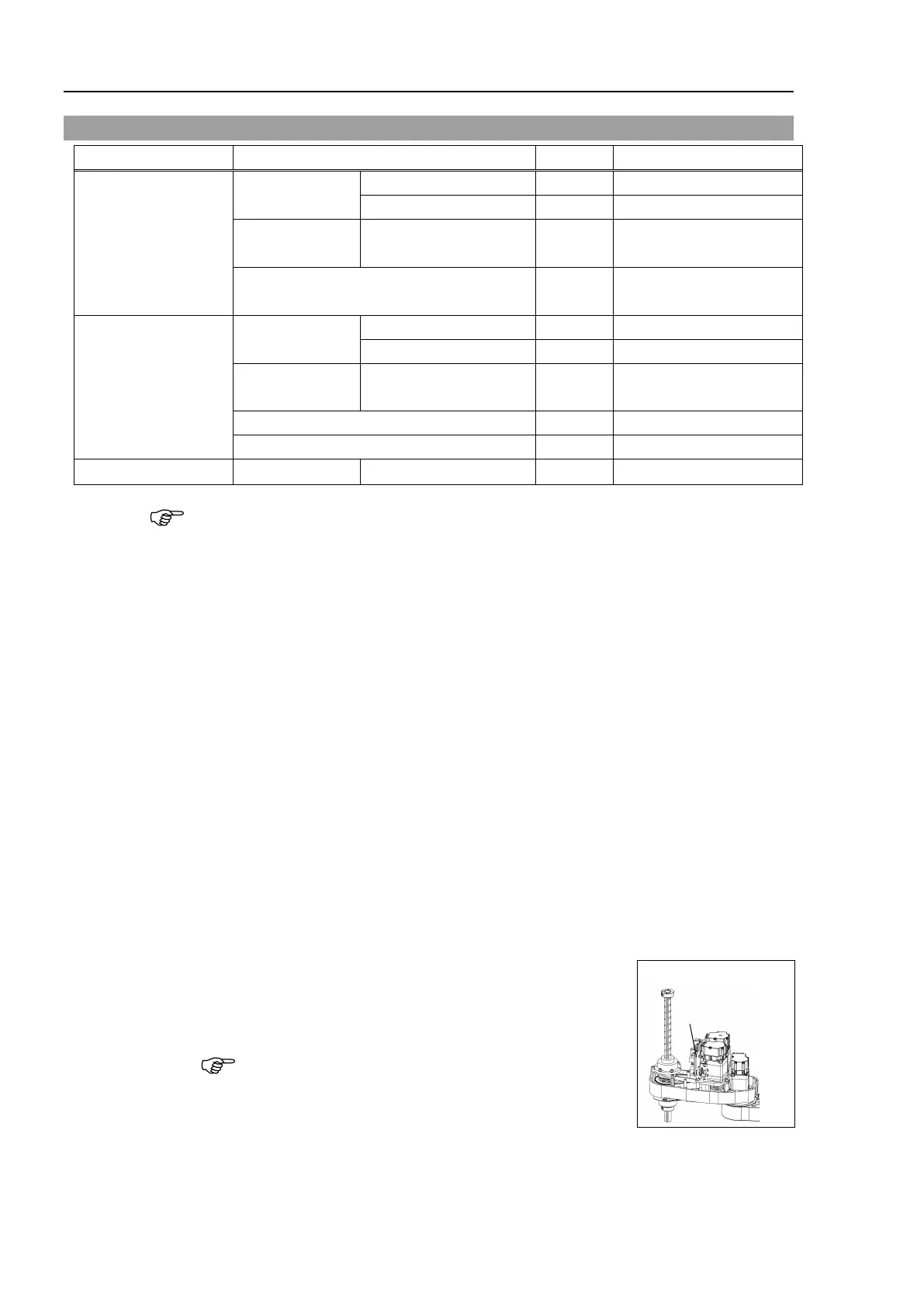

T3-B T6-B Maintenance 10. Joint #2

74 T-B series Maintenance Manual Rev.1

10.1 Replacing Joint #2 Motor

Maintenance

part

Motor

O-ring

Between reduction gear

units and Arm #2

1

T3-B: 1868478

Elliptic cam positioning jig 1

T3-B: 1875189

Tools

Hexagonal

Cross-point

No.2 1 For cross-recessed screw

A brake is mounted on the Joint #3 motor to prevent the shaft from lowering down due to the

weight of the end effector while the power to the Manipulator is OFF or while the motor is

in OFF status (MOTOR OFF).

Refer to removal steps to move the shaft down to its lower limit before the replacement

procedure.

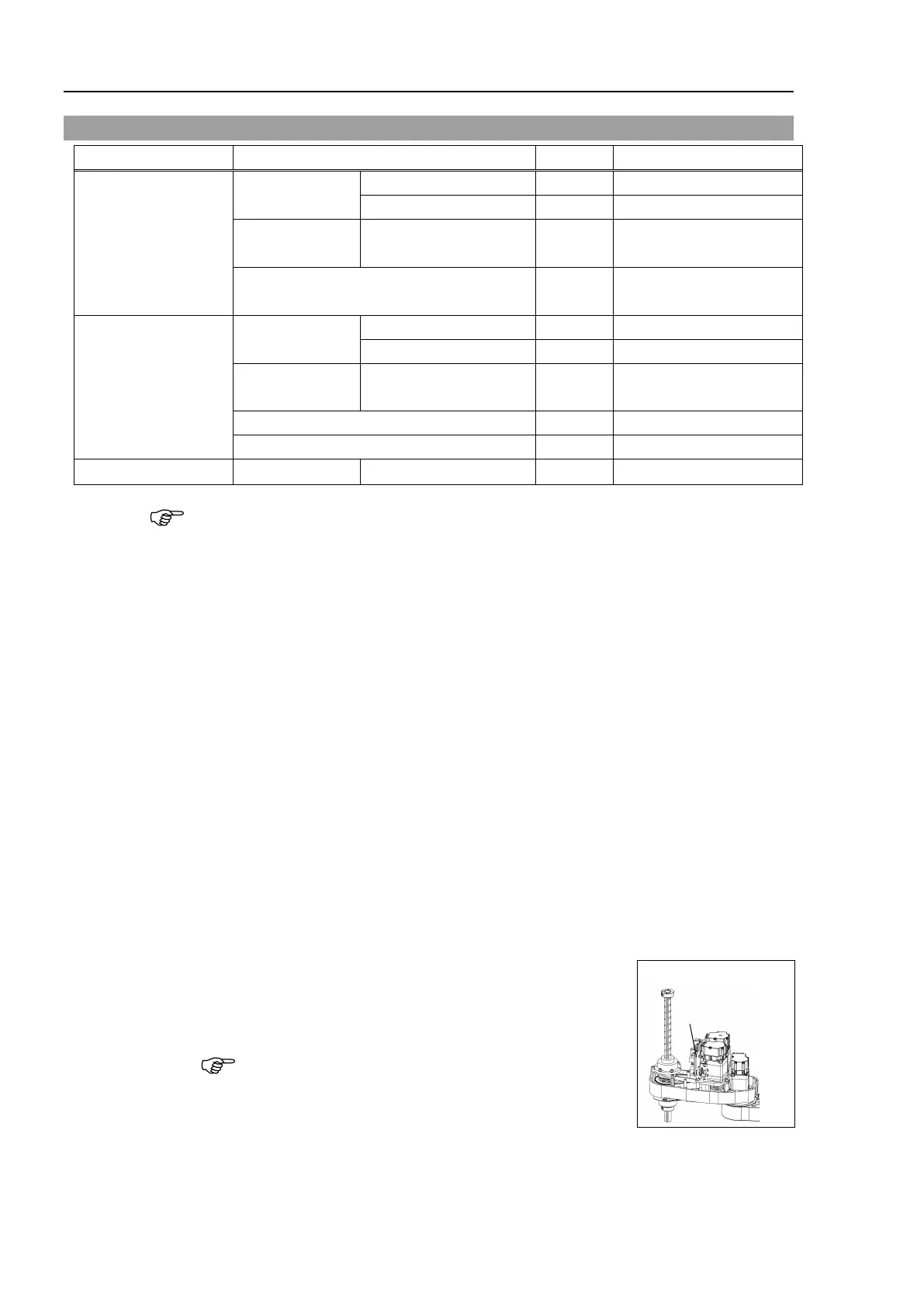

Motor

Press and hold the brake release switch to let the shaft down. Be sure to keep enough

space and prevent the end effe

ctor hitting any peripheral equipment.

The brake release switch affects only Joint #3. When the brake release switch is pressed,

the Joint #3 brake is released.

Be careful of the shaft falling while the brake release switch is being pressed because

the sh

aft may be lowered by the weight of the end effector.

Turn OFF the Manipulator.

Remove the Arm Top Cover.

Reference: 7.1 Arm Top Cover

Reference: 7.7 User Plate

Loosen the mounting screws of the Joint #2,

3, 4 AMP board

unit, and remove the board unit from Arm #2.

2-M3×10 Sems

Do not remove the mounting screws and the connector.

Joint #2

, 3, 4

AMP Board Unit

Loading...

Loading...