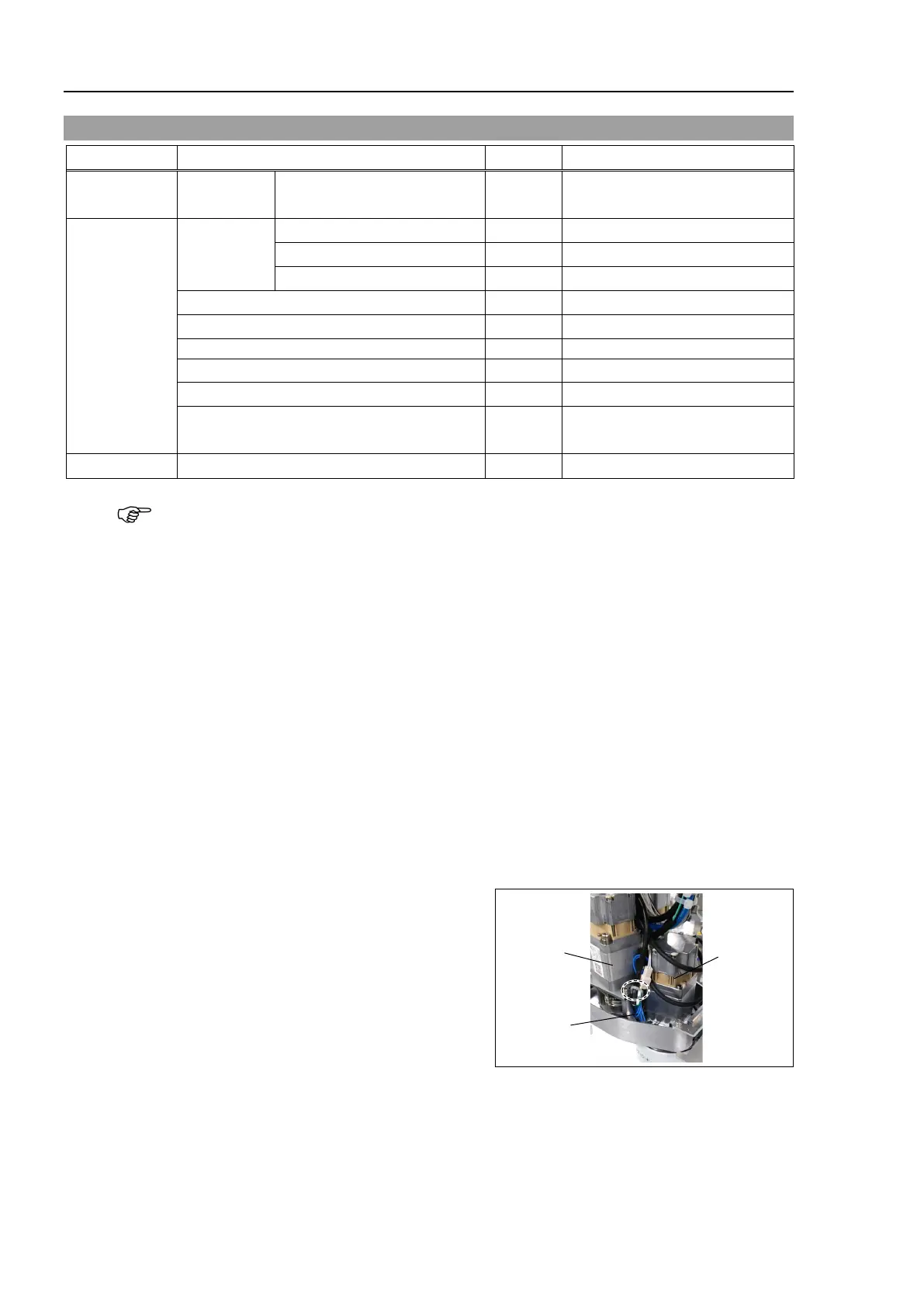

T3-B T6-B Maintenance 11. Joint #3

84 T-B series Maintenance Manual Rev.1

11.1 Replacing Joint #3 Motor

Maintenance

Motor 100W 1 2216544

Tools

Hexagonal

wrench

Width across flats: 1.5 mm

For M3 set screw and M2 screw

Width across flats: 2.5 mm

Cross-point screwdriver (No. 2)

Z: Belt tension 69N (7.0±0.5kgf)

Suitable cord (Length about 800mm)

Feeler gage (0.5mm) 2

For adjusting the pulley securing

A brake is mounted on the Joint #3 motor to prevent the shaft from lowering down due to the

weight of the end effector while the power to the Manipulator is OFF or while the motor is

in OFF status (MOTOR OFF).

Move the shaft down to its lower limit before the replacement procedure following the

removal steps.

Press and hold the brake release switch to let the shaft down. Be sure to keep enough space

and prevent the end effector hitting any peripheral equipment.

The brake release switch affects only Joint #3. When the brake release switch is pressed,

the Joint #3 brake is released.

Be careful of the shaft falling while the brake release switch is being pressed because the

shaft may be lowered by the weight of the end effector.

Turn OFF the Manipulator.

Remove the arm top cover.

Reference: 7.1 Arm Top Cover

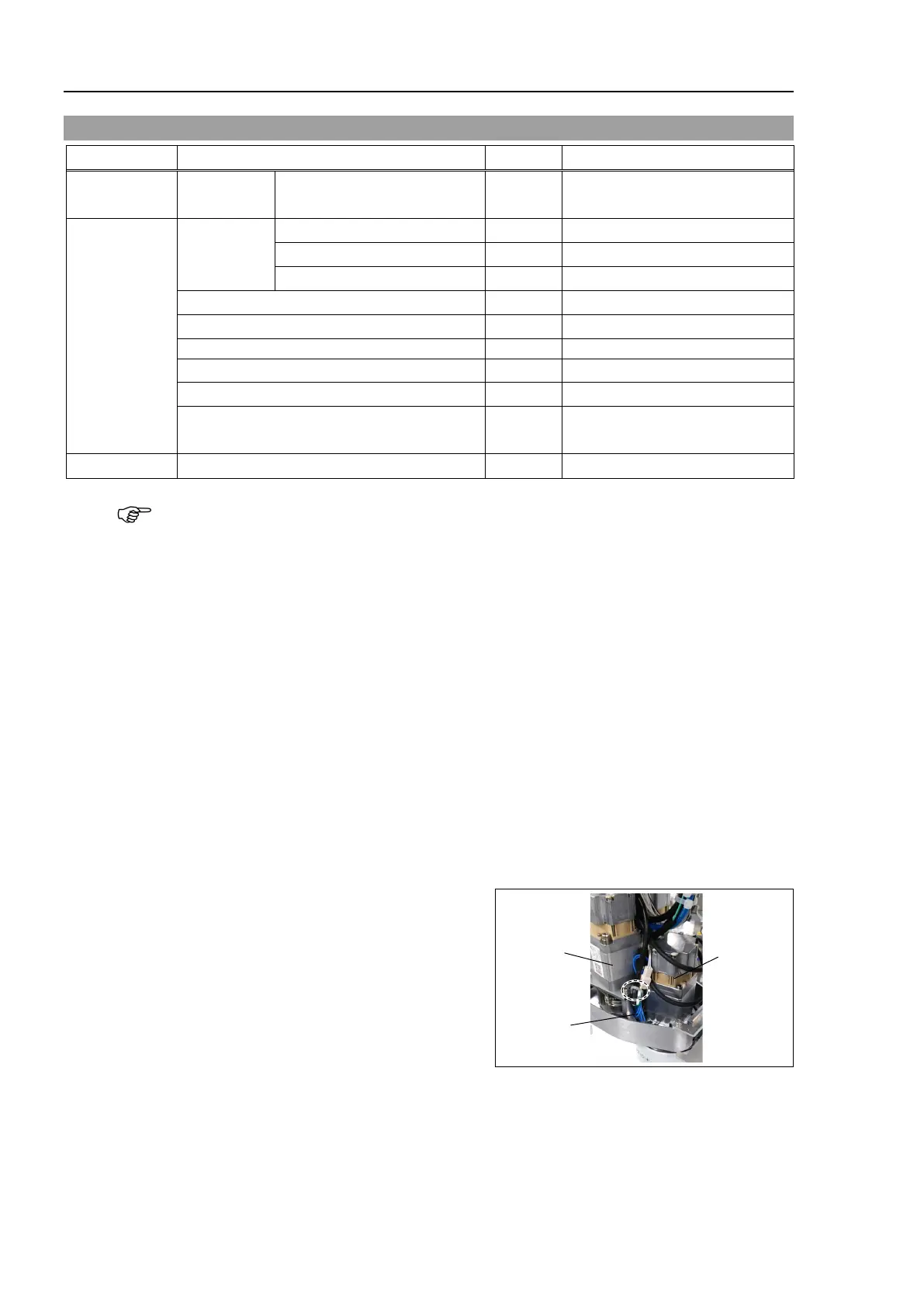

Cut off the wire tie binding the brake

cables.

Loading...

Loading...