48 05 2013 4365 00

Conduits and mixers

Periodically, apart from the external parts of the mixers

which need to be cleaned of any powder residue, par-

ticularly in the funnel area, the parts of the mixer which

are in contact with the drink should also be sterilised.

Absolutely do not use jets of water for cleaning.

The parts that need to be cleaned are:

- Powder funnels, mixers and instant drinks dispensing

pipes;

- Pipes and dispensing nozzles;

- Dispensing unit.

Open the cover of the mixer dispensing cell and lift the

powder nozzles up to the end stop.

- Remove the powder funnels, the water conveyors, the

powder deposit funnels and the mixer motor fans from

the mixers;

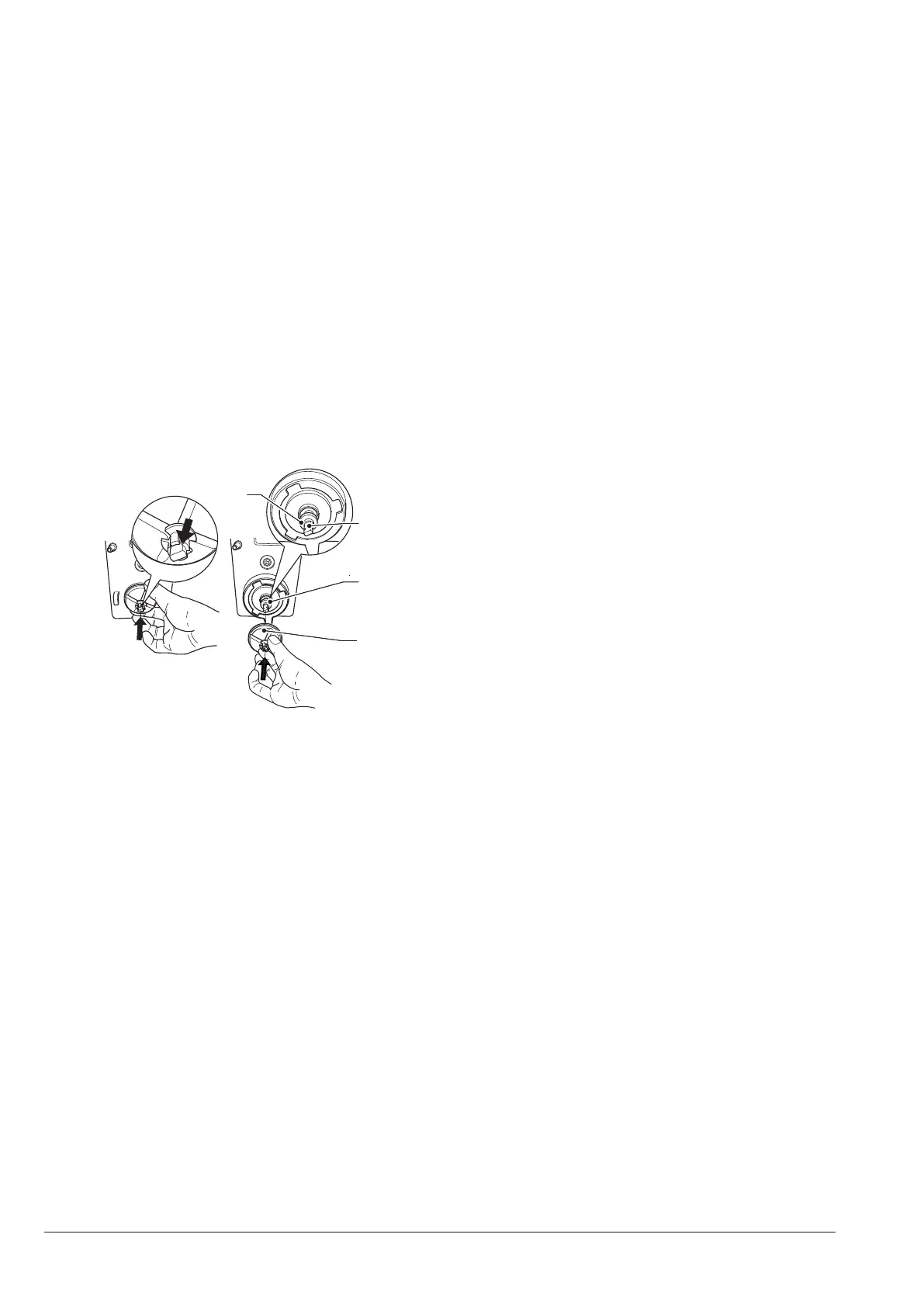

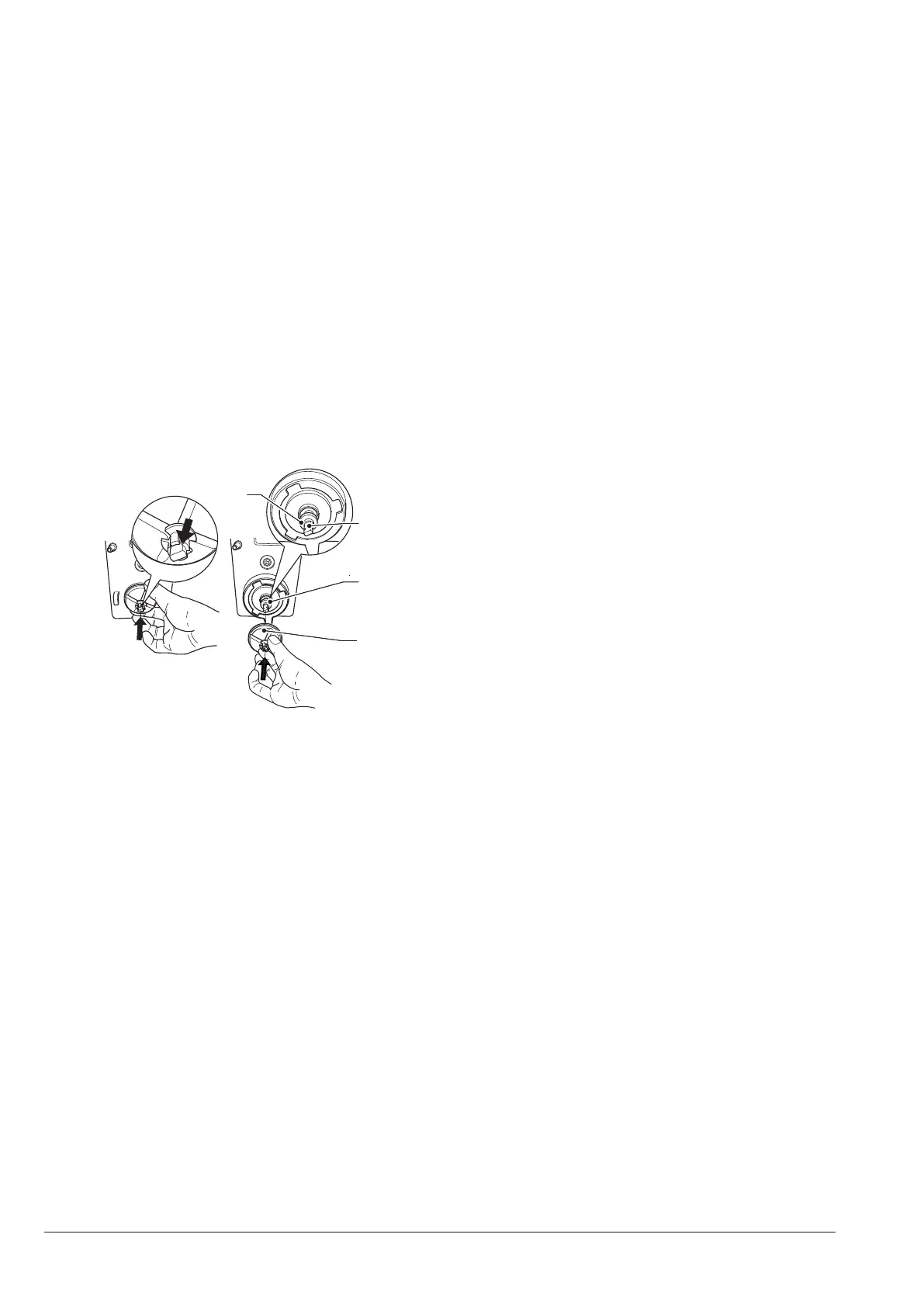

- the fans can be removed by simply pulling gently to free

them (see Fig. 28);

1

2

3

2

Fig. 32

1- Fan

2- Stuffing box seal

3- Shaft discharge

- Verify that the stuffing box lip seal is not broken and

has not lost elasticity; for inserting it, place the seal just

beyond the shaft discharge.

By inserting the fan completely, the stuffing box seal will

assume the correct position (see Fig. 28).

- Wash all the components with sterilising products (fol-

low the dosage indicated by the manufacturer), being

careful to mechanically remove the visible residues

using brushes if necessary.

The sterilisation is performed by means of sterilising

products.

- Dip the parts for approx. 20 minutes in a recipient con-

taining the previously prepared sterilising solution.

- Reinstall the conveyors and the water funnels.

- Reinstall the powder deposit drawers and the powder

funnels after having carefully rinsed and dried them.

- When reassembling the fans make sure to insert them

completely until they click.

After installing the components it is however neces-

sary:

- To wash the mixer and add a few drops of the sterilising

solution into the various funnels.

- Once the sterilisation has been performed, rinse the

components well in order to remove any possible resi-

due of the solution used.

Loading...

Loading...