Design and function

TIG welding

099-000121-EW501

29.06.2015

5.9 TIG welding

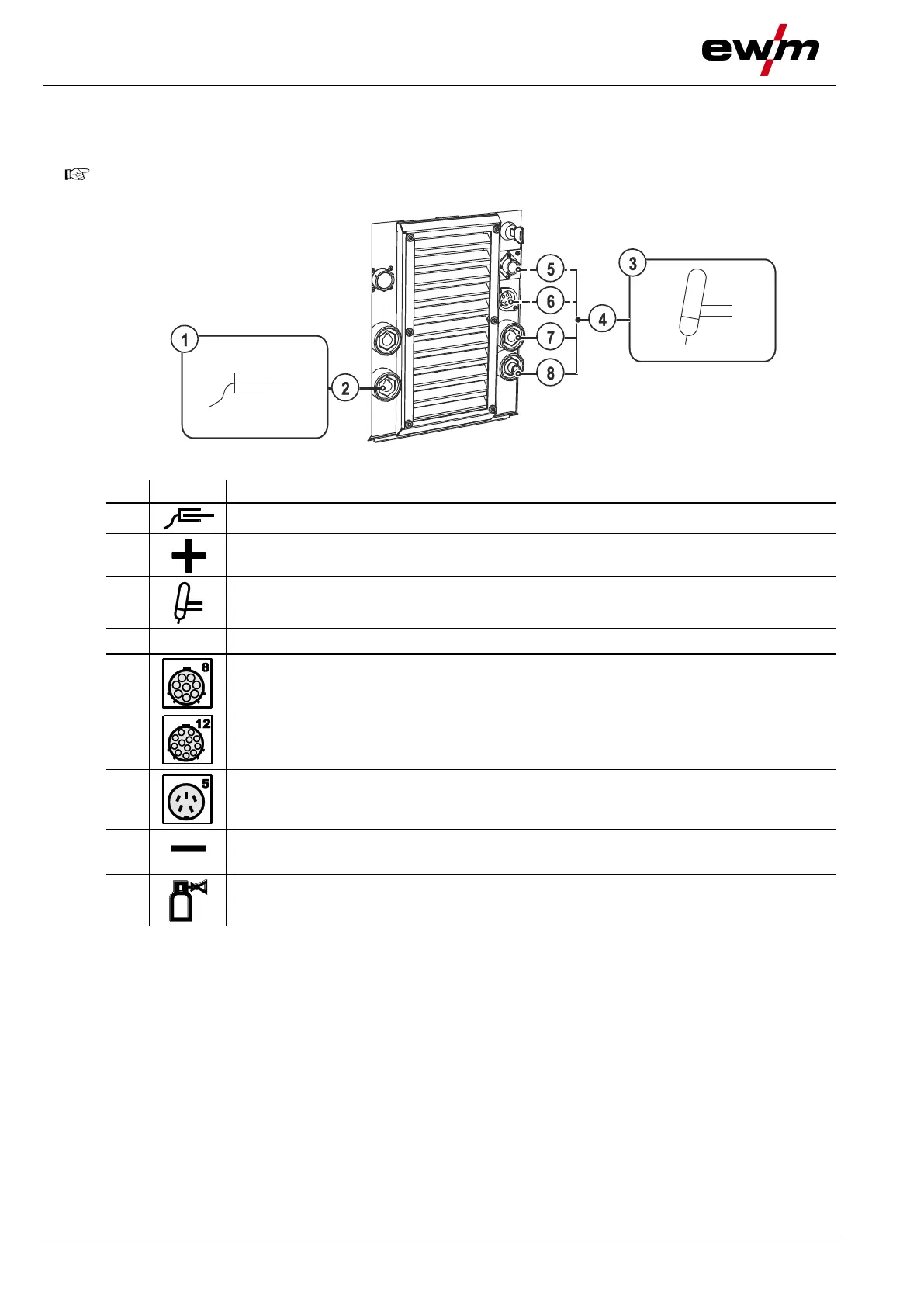

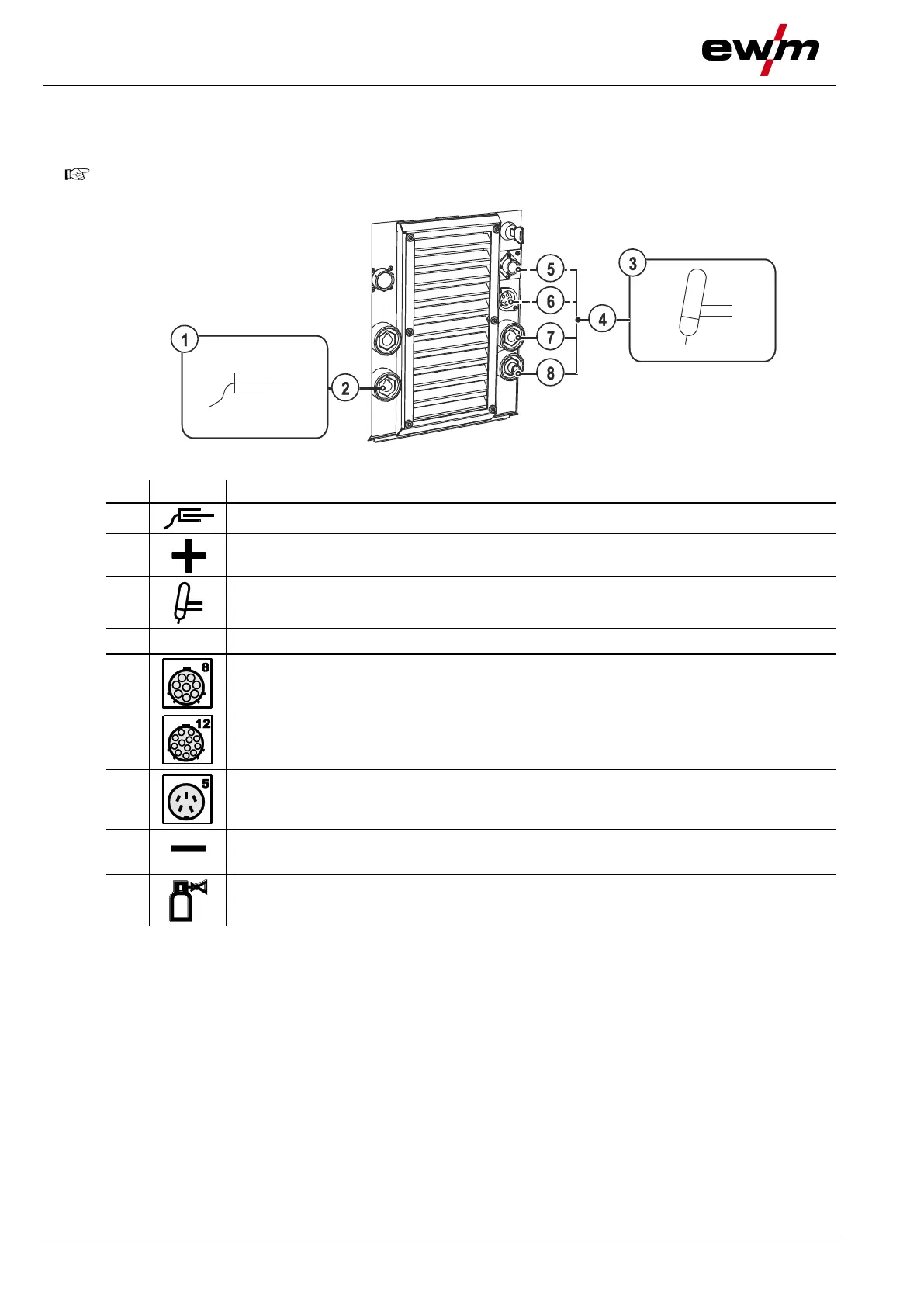

5.9.1 Welding torch and workpiece line connection

Prepare welding torch according to the welding task in hand (see operating instructions for the

torch).

Figure 5-7

Connection socket for "+" welding current

Workpiece lead connection

Welding torch hose package

Connection socket, 8-pole/12-pole (depending on variant)

8-pole: Control cable TIG up/down or potentiometer torch

12-pole: Control cable TIG up/down torch with LED display (option)

Connection socket, 5-pole

Standard TIG torch control lead

Connection socket, "-" welding current

Welding current lead connection for TIG welding torch

G¼" connecting nipple

TIG welding torch shielding gas connection

• Insert the welding current plug on the welding torch into the welding current connection socket and

lock by turning to the right.

• Remove yellow protective cap on G¼ connecting nipple.

• Screw welding torch shielding gas connection tightly onto the G¼" connection nipple.

• Insert the welding torch control lead plug into the connection socket for the welding torch control lead

(5-pole with standard torch, 8-pole with up/down or potentiometer torch and 12-pole with up/down

torch with LED display) and tighten.

• Insert the cable plug on the work piece lead into the "+" welding current connection socket and lock by

turning to the right.

Loading...

Loading...